Calendered paper undergoes a smoothing process through rollers, resulting in a glossy, polished finish ideal for high-quality printing and detailed images. Uncalendered paper retains a rougher texture with a matte appearance, providing better ink absorption and a more tactile feel suitable for artistic or industrial applications.

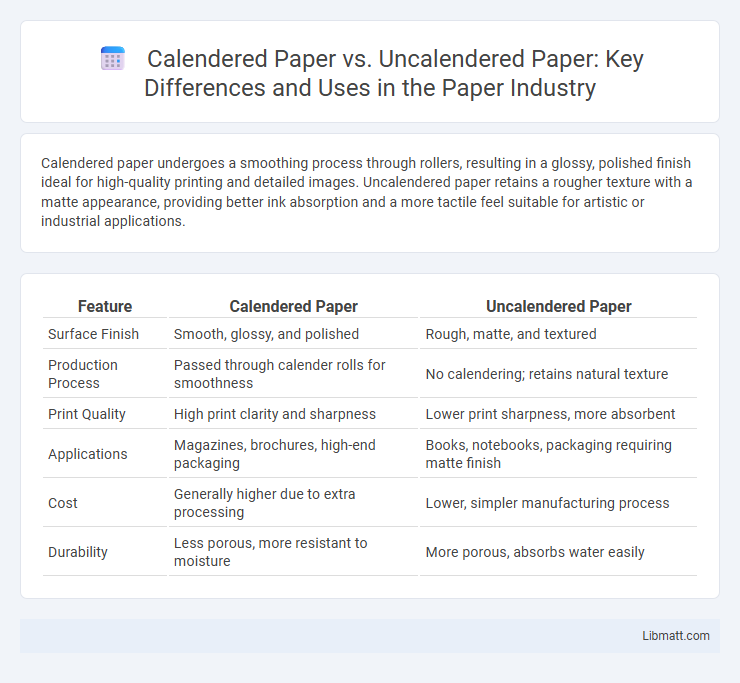

Table of Comparison

| Feature | Calendered Paper | Uncalendered Paper |

|---|---|---|

| Surface Finish | Smooth, glossy, and polished | Rough, matte, and textured |

| Production Process | Passed through calender rolls for smoothness | No calendering; retains natural texture |

| Print Quality | High print clarity and sharpness | Lower print sharpness, more absorbent |

| Applications | Magazines, brochures, high-end packaging | Books, notebooks, packaging requiring matte finish |

| Cost | Generally higher due to extra processing | Lower, simpler manufacturing process |

| Durability | Less porous, more resistant to moisture | More porous, absorbs water easily |

Introduction to Calendered and Uncalendered Paper

Calendered paper undergoes a finishing process where it is passed through heated rollers to achieve a smooth, glossy surface ideal for high-quality printing and vibrant color reproduction. Uncalendered paper retains a rougher texture, providing better ink absorption and a more natural, tactile feel suitable for artistic prints and packaging materials. Your choice between calendered and uncalendered paper depends on the desired finish, print quality, and functional requirements of your project.

Understanding the Calendering Process

The calendering process involves passing paper through heated rollers to create a smooth, glossy finish by compressing fibers and reducing thickness variations. Calendered paper exhibits enhanced surface uniformity, improved brightness, and better printability compared to uncalendered paper, which retains a rougher texture and higher porosity. This finishing technique directly affects paper quality, making calendered paper ideal for high-resolution printing and graphic applications.

Key Characteristics of Calendered Paper

Calendered paper features a smooth, glossy surface achieved through a series of rollers that compress the paper fibers, enhancing print quality and image sharpness. Its even texture and reduced porosity make it ideal for high-resolution printing, delivering vibrant colors and detailed graphics. You benefit from calendered paper's consistent finish that improves both the aesthetic appeal and durability of printed materials.

Defining Features of Uncalendered Paper

Uncalendered paper is characterized by its rough surface texture and higher porosity compared to calendered paper, making it ideal for applications requiring enhanced ink absorption and superior grip. Unlike calendered paper, which undergoes a smoothing process using heated rollers to achieve a glossy finish and reduced thickness, uncalendered paper retains its natural, fibrous feel and increased bulk. These defining features make uncalendered paper suitable for packaging, labels, and artistic printing where texture and ink receptivity are crucial.

Surface Finish: Smoothness and Texture Comparison

Calendered paper undergoes a finishing process where it passes through heated rollers, resulting in a smooth, glossy surface with enhanced brightness and uniform texture ideal for high-quality printing. Uncalendered paper retains a rougher, more fibrous texture due to the absence of this finishing step, offering better ink absorption but less surface sheen. The choice between calendered and uncalendered paper significantly impacts print clarity, color vibrancy, and tactile experience in applications such as packaging, labels, and fine art printing.

Print Quality: Calendered vs Uncalendered Paper

Calendered paper offers a smoother, more uniform surface that enhances print quality by providing sharper images and vibrant colors, ideal for high-resolution printing. Uncalendered paper has a rougher texture, which reduces ink absorption control, resulting in a more matte finish and less precise image reproduction. The choice between calendered and uncalendered paper significantly impacts print sharpness, color accuracy, and overall visual appeal in printed materials.

Typical Applications and Industry Uses

Calendered paper, with its smooth, glossy finish, is commonly used in high-quality printing, packaging, and graphic arts where enhanced image reproduction and surface uniformity are critical, such as magazines, brochures, and product labels. Uncalendered paper, characterized by its rougher texture and higher absorbency, finds extensive application in packaging, industrial wrapping, and artistic uses where strength and ink absorption are prioritized, such as kraft papers, grocery bags, and watercolors. Both paper types serve diverse industries including publishing, retail packaging, and fine arts, chosen based on the required surface properties and mechanical strength.

Cost Differences and Economic Considerations

Calendered paper typically incurs higher production costs due to the additional smoothing and finishing processes involved, which enhance surface gloss and print quality. Uncalendered paper is generally more economical, making it suitable for bulk printing tasks where surface finish is less critical. Businesses must weigh the increased expense of calendered paper against the value of premium print results when considering budget constraints and project requirements.

Environmental Impact and Sustainability

Calendered paper undergoes a smoothing process that uses more energy and chemicals, resulting in a higher environmental footprint compared to uncalendered paper, which retains its natural texture and requires less processing. Uncalendered paper often supports sustainability efforts by minimizing chemical use and energy consumption, making it a better choice for eco-conscious applications. Choosing uncalendered paper can help reduce your environmental impact through lower resource usage and enhanced recyclability.

Choosing the Right Paper for Your Project

Calendered paper features a smooth, glossy finish achieved through pressing between rollers, making it ideal for high-quality printing and detailed images. Uncalendered paper retains a textured, matte surface that enhances ink absorption, suitable for projects requiring a natural or rustic look. Selecting the right paper depends on your project's aesthetic goals and printing needs, where calendered paper delivers sharpness and shine, while uncalendered offers better texture and ink hold.

Calendered paper vs uncalendered paper Infographic

libmatt.com

libmatt.com