Testliner is made primarily from recycled fibers and is often used for outer layers in corrugated packaging, offering cost-effective strength. Kraftliner consists of virgin fibers, providing higher durability and moisture resistance, making it ideal for heavy-duty cartons where Your packaging requires superior quality.

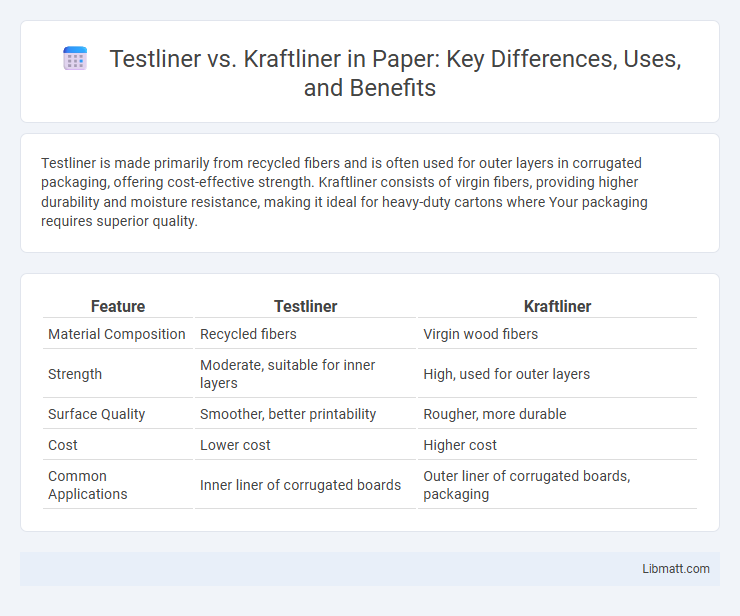

Table of Comparison

| Feature | Testliner | Kraftliner |

|---|---|---|

| Material Composition | Recycled fibers | Virgin wood fibers |

| Strength | Moderate, suitable for inner layers | High, used for outer layers |

| Surface Quality | Smoother, better printability | Rougher, more durable |

| Cost | Lower cost | Higher cost |

| Common Applications | Inner liner of corrugated boards | Outer liner of corrugated boards, packaging |

Overview of Testliner and Kraftliner

Testliner is a recycled fiber-based paperboard commonly used for packaging and carton production, known for its cost-effectiveness and decent strength. Kraftliner, made from virgin wood fibers through the kraft process, offers superior durability, higher tear resistance, and better water resistance, making it ideal for heavy-duty packaging. Both types serve distinct purposes, with testliner favoring economical and sustainable applications, while kraftliner supports high-strength packaging needs.

Key Differences Between Testliner and Kraftliner

Testliner is made from recycled fibers and is primarily used for the inner layers of corrugated cardboard, offering cost-effectiveness and eco-friendliness, while Kraftliner is produced from virgin wood pulp, providing higher strength and durability suitable for outer layers. The key differences lie in their fiber source, strength properties, and application; Kraftliner delivers superior tear resistance and stiffness, essential for packaging that requires robust protection. Your choice depends on whether you prioritize sustainability and cost savings with Testliner or high-performance durability with Kraftliner.

Raw Materials Used in Testliner and Kraftliner

Testliner is primarily produced from recycled fiber, utilizing recovered paper materials such as old newspapers, magazines, and office paper, which contributes to its cost-effectiveness and sustainability. Kraftliner, however, is manufactured from virgin long fiber pulp derived mainly from softwood trees, offering superior strength and durability suited for heavy-duty packaging. The raw material composition directly influences the mechanical properties and applications of testliner and kraftliner in the packaging industry.

Strength and Durability Comparison

Testliner and kraftliner both serve as essential materials in packaging, with kraftliner exhibiting superior strength and durability due to its virgin pulp composition and higher fiber quality. Kraftliner's robust structure offers greater resistance to tears, punctures, and moisture, making it ideal for heavy-duty packaging applications. Testliner, often made from recycled fibers, provides moderate strength suitable for lighter packaging needs but generally falls short in durability compared to kraftliner.

Environmental Impact and Sustainability

Testliner and kraftliner differ significantly in environmental impact and sustainability due to their raw material sources and production processes. Testliner is primarily produced from recycled paper fibers, reducing deforestation and promoting circular economy principles, while kraftliner is made from virgin wood pulp, offering higher durability but a greater environmental footprint from logging activities. Choosing testliner supports waste reduction and energy savings, whereas kraftliner's longevity can decrease overall material consumption in heavy-duty packaging applications.

Typical Applications of Testliner

Testliner is primarily used for the production of corrugated board and packaging materials due to its cost-effectiveness and adequate strength properties. It often serves as the outer and inner layers of corrugated boxes, providing a smooth surface for printing and good recyclability. Your choice of testliner ensures efficient packaging solutions, especially in food, retail, and industrial sectors.

Typical Applications of Kraftliner

Kraftliner is primarily used in the production of heavy-duty packaging materials such as corrugated boxes and shipping containers due to its high strength and durability. It is suitable for applications requiring superior load-bearing capacity and resistance to punctures, often found in industries like automotive, industrial goods, and food packaging. Unlike testliner, which is commonly used for inner layers or recycled content, kraftliner is typically employed as the outer liner to provide structural integrity and protection.

Cost Analysis: Testliner vs Kraftliner

Testliner generally offers a more cost-effective solution compared to kraftliner due to its use of recycled fibers, reducing raw material expenses and production costs. Kraftliner, made primarily from virgin fibers, incurs higher manufacturing costs but provides superior strength and durability, which may justify the premium in applications requiring robust packaging. An effective cost analysis balances the lower price point of testliner with the enhanced performance and longevity benefits provided by kraftliner, depending on specific project requirements.

Industry Standards and Certifications

Testliner and kraftliner comply with industry standards such as ISO 9001 for quality management and FSC certification ensuring sustainable sourcing. Kraftliner typically meets higher strength and durability standards, aligning with regulations for heavy-duty packaging applications. Testliner often adheres to recycling content guidelines, making it suitable for eco-friendly and cost-effective packaging solutions.

Choosing the Right Liner for Your Packaging Needs

Testliner offers a cost-effective, recycled fiber-based option ideal for lightweight packaging and environmentally friendly solutions, while Kraftliner provides superior strength and durability with virgin fibers, perfect for heavy-duty or high-performance packaging. Your choice depends on balancing budget constraints with the need for toughness and moisture resistance, where Kraftliner excels in protecting fragile or heavy items. Evaluating the specific requirements of your packaging, such as weight, sustainability goals, and durability, ensures you select the optimal liner for your product's protection and presentation.

Testliner vs kraftliner Infographic

libmatt.com

libmatt.com