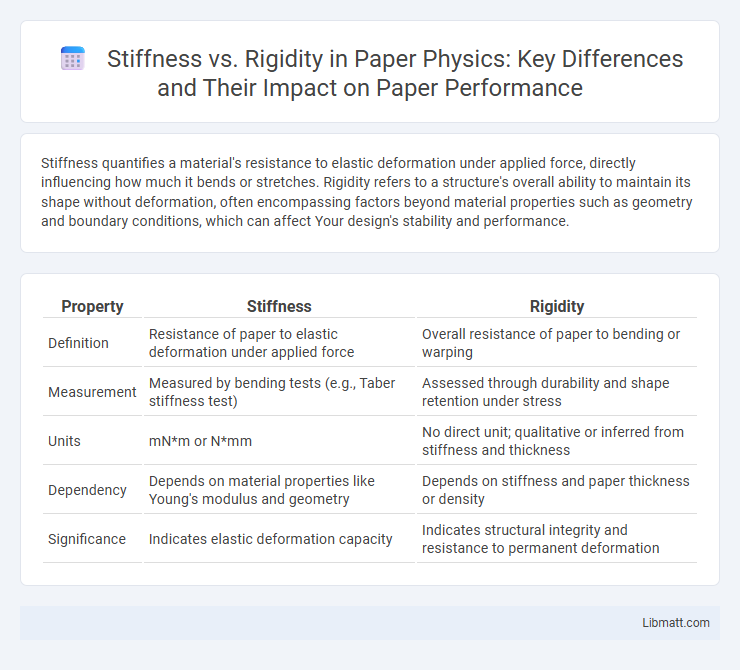

Stiffness quantifies a material's resistance to elastic deformation under applied force, directly influencing how much it bends or stretches. Rigidity refers to a structure's overall ability to maintain its shape without deformation, often encompassing factors beyond material properties such as geometry and boundary conditions, which can affect Your design's stability and performance.

Table of Comparison

| Property | Stiffness | Rigidity |

|---|---|---|

| Definition | Resistance of paper to elastic deformation under applied force | Overall resistance of paper to bending or warping |

| Measurement | Measured by bending tests (e.g., Taber stiffness test) | Assessed through durability and shape retention under stress |

| Units | mN*m or N*mm | No direct unit; qualitative or inferred from stiffness and thickness |

| Dependency | Depends on material properties like Young's modulus and geometry | Depends on stiffness and paper thickness or density |

| Significance | Indicates elastic deformation capacity | Indicates structural integrity and resistance to permanent deformation |

Introduction to Stiffness and Rigidity in Paper Physics

In paper physics, stiffness refers to a material's resistance to bending or deformation under applied force, directly influencing the paper's durability and usability in printing and packaging. Rigidity, on the other hand, describes the inherent structural resistance to shape changes without permanent deformation, reflecting the paper's ability to maintain form under stress. Your understanding of both stiffness and rigidity is essential for optimizing paper quality and performance in various engineering and industrial applications.

Defining Stiffness: What It Means in Paper Science

Stiffness in paper science refers to the resistance of paper to bending or deformation under an applied force, primarily influenced by fiber orientation, thickness, and bonding. It quantifies how much a paper sheet can withstand load without significant deflection, crucial for packaging and printing applications requiring dimensional stability. Unlike rigidity, which denotes overall structural inflexibility, stiffness specifically measures elastic resistance to bending at given stress levels in paper materials.

Understanding Rigidity: The Fundamentals

Rigidity in paper physics refers to the material's resistance to deformation under applied force, fundamentally dictated by the fiber network structure and bonding strength. It measures the ability to maintain shape without bending, influenced by factors such as fiber length, density, and moisture content. Precise evaluation of rigidity helps optimize paper performance in applications requiring dimensional stability and structural integrity.

Key Differences Between Stiffness and Rigidity

Stiffness in paper physics refers to the material's resistance to deformation under applied force, quantified by the modulus of elasticity and measured using bending or tensile tests. Rigidity denotes the structural property of an object or assembly that resists deformation, influenced by shape, size, and support conditions rather than solely material properties. Key differences include stiffness being a material-specific characteristic, whereas rigidity depends on both material stiffness and geometric configuration, affecting paper strength and performance in applications like packaging and printing.

Measurement Methods for Stiffness in Paper

Stiffness in paper is commonly measured using instruments like the Taber stiffness tester, which quantifies bending resistance by applying a fixed force to a paper sample and recording the degree of deflection. Another prevalent method involves the Gurley stiffness tester that measures the force required to bend a standardized paper strip through a specified angle. Dynamic mechanical analysis (DMA) also provides precise stiffness measurements by applying oscillating forces and assessing the material's mechanical response over a range of frequencies and temperatures.

Techniques for Assessing Rigidity of Paper Materials

Techniques for assessing the rigidity of paper materials often involve three-point bending tests and dynamic mechanical analysis (DMA), which quantify resistance to deformation under applied forces. Measurements of flexural modulus and stiffness coefficients help determine the paper's ability to retain shape under mechanical stress. Advanced imaging methods, such as scanning electron microscopy (SEM), provide insights into fiber orientation and bonding that influence the material's rigidity.

Factors Influencing Stiffness and Rigidity in Paper

Fiber composition, moisture content, and paper density significantly influence stiffness and rigidity in paper, with higher cellulose content and low moisture enhancing stiffness. The paper's internal bonding and fiber orientation contribute to rigidity by resisting deformation under stress. Calendering and coating processes also affect these properties by altering surface smoothness and fiber interlocking, which impacts the paper's mechanical strength.

Practical Applications: When to Prioritize Stiffness vs Rigidity

In paper physics, stiffness determines how well a paper resists bending under load, while rigidity refers to its resistance to deformation under applied stress. Practical applications prioritize stiffness when structural stability and maintaining shape in printing or packaging are critical, whereas rigidity is emphasized for durability and resistance to mechanical forces during handling or processing. Understanding the difference helps you select paper that optimizes performance based on the specific demands of your project or manufacturing process.

Impact of Stiffness and Rigidity on Paper Performance

Stiffness and rigidity critically influence paper performance by determining its ability to resist deformation under applied forces, directly affecting handling and printing quality. High stiffness improves paper flatness and durability, ensuring smoother feed through printing machines, while rigidity impacts the paper's resistance to bending and folding stresses during usage. Optimizing your paper's stiffness and rigidity balance enhances overall product reliability and user experience in various applications.

Optimizing Paper Design for Desired Stiffness and Rigidity

Optimizing paper design for desired stiffness and rigidity requires precise control over fiber orientation, sheet density, and moisture content to achieve structural integrity without compromising flexibility. Enhancing stiffness involves increasing the modulus of elasticity through fiber bonding and sheet consolidation, while rigidity depends on geometric factors such as thickness and curvature. Your paper's performance in packaging or printing applications benefits from balancing these properties to meet specific mechanical requirements.

Stiffness vs rigidity (paper physics) Infographic

libmatt.com

libmatt.com