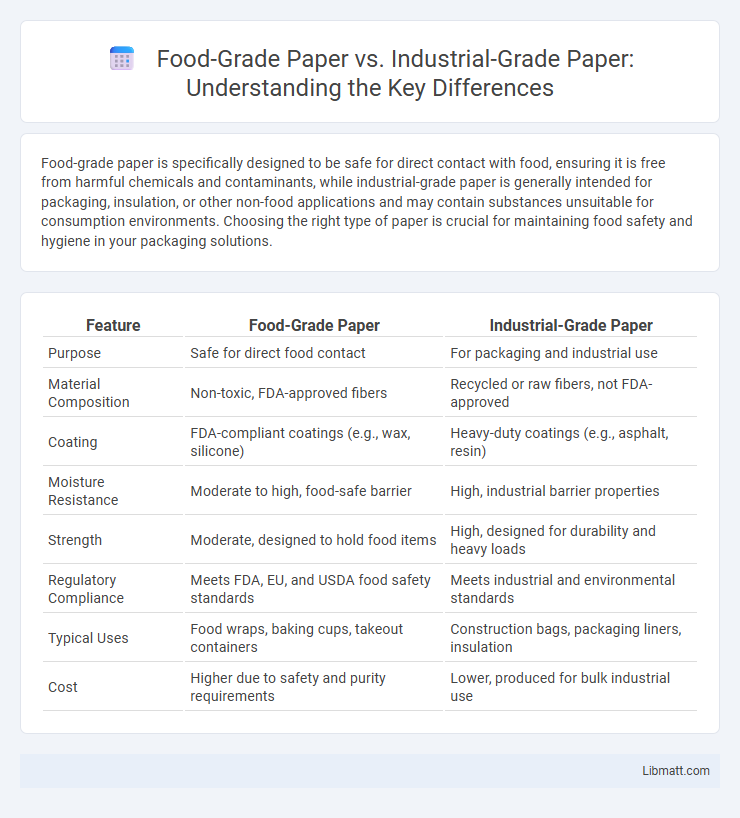

Food-grade paper is specifically designed to be safe for direct contact with food, ensuring it is free from harmful chemicals and contaminants, while industrial-grade paper is generally intended for packaging, insulation, or other non-food applications and may contain substances unsuitable for consumption environments. Choosing the right type of paper is crucial for maintaining food safety and hygiene in your packaging solutions.

Table of Comparison

| Feature | Food-Grade Paper | Industrial-Grade Paper |

|---|---|---|

| Purpose | Safe for direct food contact | For packaging and industrial use |

| Material Composition | Non-toxic, FDA-approved fibers | Recycled or raw fibers, not FDA-approved |

| Coating | FDA-compliant coatings (e.g., wax, silicone) | Heavy-duty coatings (e.g., asphalt, resin) |

| Moisture Resistance | Moderate to high, food-safe barrier | High, industrial barrier properties |

| Strength | Moderate, designed to hold food items | High, designed for durability and heavy loads |

| Regulatory Compliance | Meets FDA, EU, and USDA food safety standards | Meets industrial and environmental standards |

| Typical Uses | Food wraps, baking cups, takeout containers | Construction bags, packaging liners, insulation |

| Cost | Higher due to safety and purity requirements | Lower, produced for bulk industrial use |

Introduction to Food-Grade and Industrial-Grade Paper

Food-grade paper meets strict safety standards set by regulatory agencies such as the FDA, ensuring it is non-toxic, free from harmful chemicals, and safe for direct contact with food products. Industrial-grade paper, typically used in packaging, insulation, or manufacturing, lacks these stringent specifications and may contain additives or coatings unsuitable for food contact. Understanding the distinction between these types is crucial for food industry compliance and consumer safety.

Defining Food-Grade Paper: Key Characteristics

Food-grade paper is specifically designed to meet stringent safety standards for direct contact with food, characterized by its non-toxic, grease-resistant, and moisture-barrier properties. It is free from harmful chemicals, additives, and contaminants, ensuring that your food remains uncontaminated and safe for consumption. These key features distinguish food-grade paper from industrial-grade paper, which lacks such rigorous quality controls and is unsuitable for packaging or handling edible products.

Understanding Industrial-Grade Paper: Uses and Properties

Industrial-grade paper is designed for heavy-duty applications such as packaging, insulation, and manufacturing processes, offering high durability, resistance to moisture, and structural strength. Unlike food-grade paper, it is not safe for direct food contact due to potential chemical treatments and additives. Understanding these properties helps you select the right paper for non-food industrial uses where performance and durability are critical.

Regulatory Standards for Food-Grade Paper

Food-grade paper must comply with stringent regulatory standards such as FDA 21 CFR Part 176 and EU Regulation No 1935/2004, ensuring it is safe for direct contact with food by limiting chemical migration and contaminants. Industrial-grade paper lacks these certifications and is typically designed for packaging or printing applications where food safety is not a concern. Compliance with these regulatory frameworks guarantees that food-grade paper maintains hygiene, prevents contamination, and preserves food quality during storage and handling.

Material Composition Differences

Food-grade paper is primarily composed of natural fibers such as cellulose derived from wood pulp, often treated to be free of harmful chemicals and additives, ensuring safety for direct contact with food. Industrial-grade paper incorporates recycled fibers, synthetic additives, and sometimes fillers to enhance durability, tensile strength, and moisture resistance, which may introduce contaminants unsuitable for food use. The absence of bleaching agents like chlorine and the use of FDA-approved materials distinguish food-grade paper from the chemically intensive compositions found in industrial-grade paper.

Application Areas: Food vs Industrial Sectors

Food-grade paper is primarily used in packaging, wrapping, and storing consumables, ensuring safety and hygiene in sectors like bakeries, fast food outlets, and grocery stores. Industrial-grade paper serves in manufacturing processes, insulation, and protective packaging within sectors such as automotive, electronics, and construction. The food sector demands compliance with strict FDA and FDA-compliant materials standards, while the industrial sector prioritizes durability and resistance to chemicals and temperature fluctuations.

Health and Safety Considerations

Food-grade paper undergoes stringent testing and certification to ensure it is free from harmful chemicals and contaminants, making it safe for direct contact with food. Industrial-grade paper often contains additives, dyes, and recycled fibers that pose health risks if used for food packaging. Choosing food-grade paper protects Your health by preventing chemical leaching and contamination during food storage or consumption.

Environmental Impact and Sustainability

Food-grade paper is designed to be biodegradable and compostable, minimizing environmental impact through its use of non-toxic, sustainably sourced fibers that reduce landfill waste. Industrial-grade paper, often treated with chemicals and coatings for durability, poses greater challenges for recycling and biodegradation, contributing to higher carbon footprints and pollution. Selecting food-grade paper supports sustainable practices by promoting circular economy principles and reducing reliance on synthetic materials.

Cost Implications and Economic Factors

Food-grade paper commands a higher price due to stringent safety standards and certifications required to prevent contamination and ensure hygiene in packaging. Industrial-grade paper, while more cost-effective, lacks these certifications and is unsuitable for direct food contact, limiting its use to secondary or external packaging. The economic trade-off involves balancing the increased material cost against compliance and consumer safety benefits in the food industry supply chain.

Choosing the Right Paper for Your Needs

Selecting food-grade paper ensures safety and compliance with health regulations, making it ideal for packaging direct-contact food items by preventing contamination and preserving freshness. Industrial-grade paper offers greater durability and cost-effectiveness for non-food applications such as shipping and packing, but it lacks FDA approval for food contact. Prioritize food-grade paper for edible products and industrial-grade paper for structural support or external packaging to meet quality and safety standards effectively.

Food-grade paper vs industrial-grade paper Infographic

libmatt.com

libmatt.com