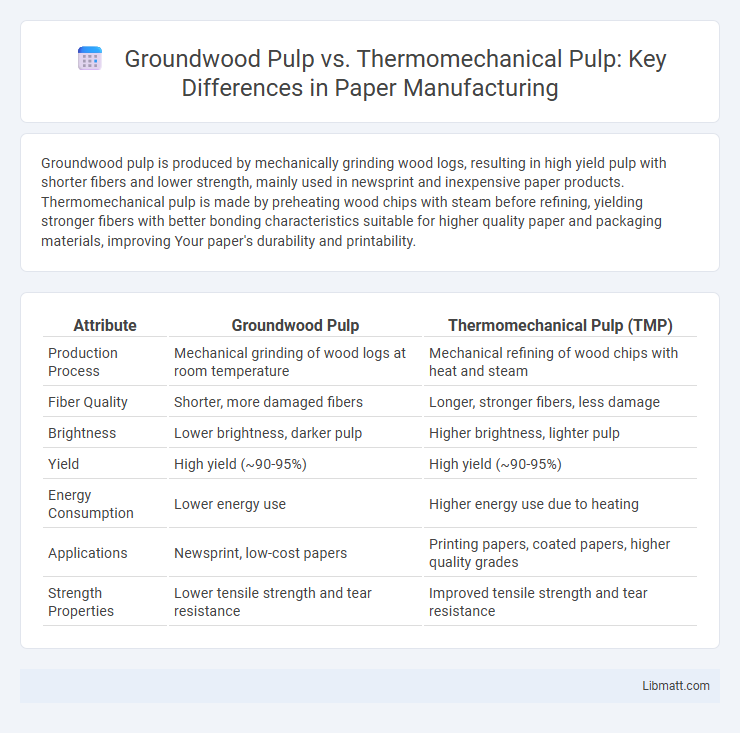

Groundwood pulp is produced by mechanically grinding wood logs, resulting in high yield pulp with shorter fibers and lower strength, mainly used in newsprint and inexpensive paper products. Thermomechanical pulp is made by preheating wood chips with steam before refining, yielding stronger fibers with better bonding characteristics suitable for higher quality paper and packaging materials, improving Your paper's durability and printability.

Table of Comparison

| Attribute | Groundwood Pulp | Thermomechanical Pulp (TMP) |

|---|---|---|

| Production Process | Mechanical grinding of wood logs at room temperature | Mechanical refining of wood chips with heat and steam |

| Fiber Quality | Shorter, more damaged fibers | Longer, stronger fibers, less damage |

| Brightness | Lower brightness, darker pulp | Higher brightness, lighter pulp |

| Yield | High yield (~90-95%) | High yield (~90-95%) |

| Energy Consumption | Lower energy use | Higher energy use due to heating |

| Applications | Newsprint, low-cost papers | Printing papers, coated papers, higher quality grades |

| Strength Properties | Lower tensile strength and tear resistance | Improved tensile strength and tear resistance |

Introduction to Groundwood Pulp and Thermomechanical Pulp

Groundwood pulp is produced by mechanically grinding wood logs against a stone, resulting in high yield pulp with short fibers and coarse texture, ideal for newsprint and lower-quality papers. Thermomechanical pulp (TMP) involves steaming wood chips before refining, which softens the fibers and improves tear strength and brightness compared to groundwood pulp. Your choice between these pulps affects paper strength, print quality, and manufacturing efficiency in various paper products.

Overview of Pulping Processes

Groundwood pulp is produced by mechanically grinding wood logs against a rotating stone, resulting in wood fibers with higher lignin content and shorter fiber length, suitable for newsprint and lower-grade paper. Thermomechanical pulp (TMP) involves steaming wood chips before refining them mechanically, which softens fibers and improves strength and brightness compared to groundwood pulp. Your choice between these pulping processes impacts paper quality, production efficiency, and the balance between fiber strength and energy consumption.

Raw Material Sources and Preparation

Groundwood pulp is produced by mechanically grinding softwood logs or chips against a stone grinder, retaining most of the wood's lignin and resulting in a high yield from raw materials like pine or spruce. Thermomechanical pulp (TMP) involves steaming wood chips to soften fibers before refining them mechanically, which enhances fiber separation and improves pulp strength compared to groundwood pulp. Your choice between these pulps depends on the desired strength and brightness, with TMP offering better fiber quality due to its refined preparation process.

Mechanical Pulping Methods: Groundwood vs Thermomechanical

Groundwood pulp is produced by grinding wood logs against a stone, resulting in fibers with high content of lignin and lower brightness, suitable for newsprint and low-grade paper. Thermomechanical pulp (TMP) uses mechanical refining of wood chips with heat and steam, producing stronger, brighter fibers with improved bulk and tear strength. The main difference lies in the TMP process enhancing fiber quality through thermal softening, while groundwood relies solely on mechanical grinding under ambient conditions.

Fiber Quality and Characteristics

Groundwood pulp consists of fibers mechanically separated from wood chips with minimal heat, resulting in shorter, more damaged fibers that reduce paper strength but enhance opacity. Thermomechanical pulp (TMP) uses heat and mechanical refining, producing longer, stronger fibers with improved bonding potential and better fiber consistency. Your choice impacts paper durability and print quality, with TMP favored for higher-strength applications and groundwood pulp suited for cost-effective, opaque printing grades.

Energy Consumption and Environmental Impact

Groundwood pulp typically consumes less energy compared to thermomechanical pulp, as it involves mechanical grinding with lower pressure and temperature requirements. Thermomechanical pulp demands higher energy input due to the use of heat and mechanical refining, leading to increased electricity consumption in production. Environmentally, groundwood pulp generates more lignin-containing fibers, resulting in higher biological oxygen demand (BOD) in effluents, whereas thermomechanical pulp's energy-intensive process contributes to a larger carbon footprint despite producing stronger fibers.

Applications in the Paper Industry

Groundwood pulp excels in producing newsprint and lower-quality paper due to its high yield and cost-effectiveness, providing good opacity and printability. Thermomechanical pulp (TMP) offers enhanced fiber strength and brightness, making it ideal for higher-quality paper products such as magazines, catalogs, and packaging materials. Your choice between groundwood pulp and TMP will impact the durability, appearance, and suitability of the paper for different publishing and packaging applications.

Cost Comparison: Groundwood Pulp vs Thermomechanical Pulp

Groundwood pulp generally offers a lower cost advantage compared to thermomechanical pulp due to its simpler production process and reduced energy consumption. Thermomechanical pulp involves higher energy inputs and more complex equipment, leading to increased operational expenses. You can expect cost differences to impact material selection significantly in large-scale paper manufacturing.

Advantages and Disadvantages of Each Pulp Type

Groundwood pulp offers high yield and cost-effectiveness by mechanically grinding wood, making it ideal for producing newsprint and low-cost paper products, but it has lower strength and brightness compared to other pulps. Thermomechanical pulp (TMP) combines mechanical grinding with heat treatment, resulting in stronger and brighter fibers suitable for higher-quality paper, though it requires more energy and higher production costs. Your choice depends on the balance between production cost, fiber quality, and the intended paper application.

Future Trends in Mechanical Pulps

Future trends in mechanical pulps highlight increased demand for energy-efficient and environmentally friendly processes, with groundwood pulp benefiting from innovations in refining technology that enhance fiber quality and reduce energy consumption. Thermomechanical pulp sees advancements in steam treatment and pressurized refining to improve fiber bonding strength and paper durability while minimizing chemical usage. Both types are evolving to meet sustainability goals, driven by industry shifts towards renewable materials and circular economy principles.

Groundwood pulp vs thermomechanical pulp Infographic

libmatt.com

libmatt.com