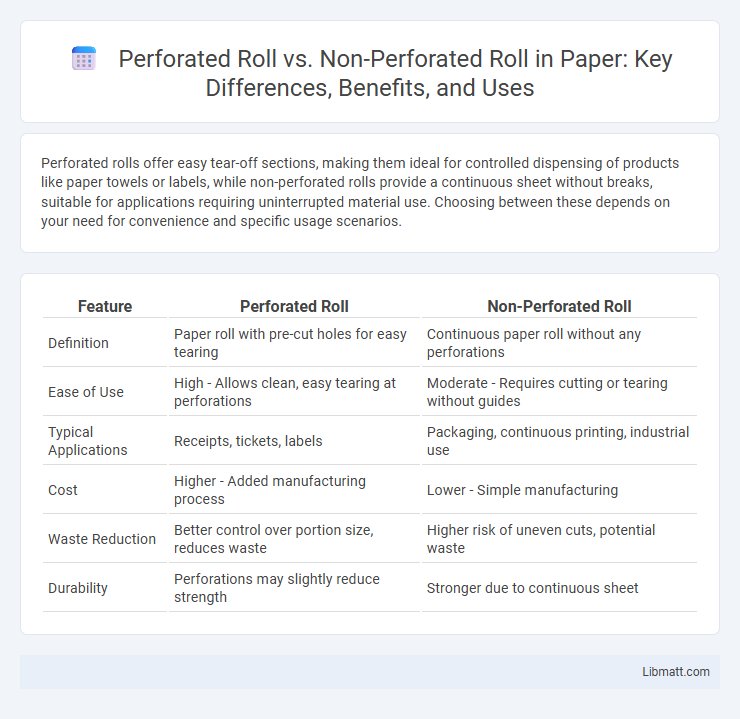

Perforated rolls offer easy tear-off sections, making them ideal for controlled dispensing of products like paper towels or labels, while non-perforated rolls provide a continuous sheet without breaks, suitable for applications requiring uninterrupted material use. Choosing between these depends on your need for convenience and specific usage scenarios.

Table of Comparison

| Feature | Perforated Roll | Non-Perforated Roll |

|---|---|---|

| Definition | Paper roll with pre-cut holes for easy tearing | Continuous paper roll without any perforations |

| Ease of Use | High - Allows clean, easy tearing at perforations | Moderate - Requires cutting or tearing without guides |

| Typical Applications | Receipts, tickets, labels | Packaging, continuous printing, industrial use |

| Cost | Higher - Added manufacturing process | Lower - Simple manufacturing |

| Waste Reduction | Better control over portion size, reduces waste | Higher risk of uneven cuts, potential waste |

| Durability | Perforations may slightly reduce strength | Stronger due to continuous sheet |

Introduction to Perforated and Non-Perforated Rolls

Perforated rolls feature evenly spaced holes designed to facilitate easy tearing or allow air and moisture passage, commonly used in packaging, baking, and industrial applications. Non-perforated rolls offer a continuous, solid surface, providing strength and containment for products requiring uninterrupted material, such as in printing or wrapping. Choosing between perforated and non-perforated rolls depends on the specific needs for durability, usability, and product protection in various industries.

Defining Perforated Roll: Key Features

Perforated rolls feature evenly spaced holes or slits that enable ventilation, drainage, or easy tearing, making them ideal for applications like packaging, medical wraps, and industrial filters. These rolls often use materials such as paper, film, or fabric, optimized for breathability and enhanced functionality. The precision of the perforation pattern directly impacts the product's usability and performance in specific applications.

Understanding Non-Perforated Roll: Essential Characteristics

Non-perforated rolls are continuous sheets without pre-cut holes or lines, offering maximum strength and durability for various applications like packaging, printing, and industrial uses. These rolls provide a smooth, uninterrupted surface ideal for customization and precise cutting to your specific size requirements. Choose non-perforated rolls when flexibility and seamless material are essential for your project's success.

Advantages of Perforated Rolls

Perforated rolls offer enhanced convenience by allowing easy tearing at precise intervals, reducing waste and improving efficiency during use. Their design ensures better portion control and cleaner handling for products like paper towels, packaging materials, or adhesive tapes. You benefit from faster application and minimized frustration compared to non-perforated rolls, which require manual cutting or tearing.

Benefits of Non-Perforated Rolls

Non-perforated rolls offer superior durability and are ideal for applications requiring continuous sheets without tear lines, such as heavy-duty packaging and industrial use. Your projects will benefit from increased strength and uniformity, ensuring materials remain intact during transport or storage. These rolls also reduce waste by allowing customized cutting, enhancing efficiency in various commercial settings.

Common Applications: Perforated vs Non-Perforated Rolls

Perforated rolls are ideal for applications requiring easy separation, such as paper towels, postage stamps, and coupons, where individual sheet removal is essential. Non-perforated rolls are commonly used for continuous printing tasks, like receipts, thermal labels, and packaging films, where uninterrupted material is necessary. Your choice between perforated and non-perforated rolls depends on whether you need quick sheet separation or a seamless, continuous feed for your specific application.

Cost Comparison: Perforated vs Non-Perforated Rolls

Perforated rolls typically cost more than non-perforated rolls due to the additional manufacturing process involved in creating the perforations. Non-perforated rolls are generally more economical for bulk use where tearing precision is less critical, making them a cost-effective choice for large-scale applications. Your decision should weigh the cost difference against the convenience and functionality that perforated rolls offer.

Environmental Impact and Sustainability Considerations

Perforated rolls reduce waste by allowing precise tearing, minimizing excess paper use compared to non-perforated rolls, which often lead to unnecessary consumption. The manufacturing process of perforated rolls incorporates energy-efficient equipment, contributing to lower carbon emissions and resource use. Choosing perforated rolls supports sustainability efforts by enhancing recycling efficiency and reducing landfill contributions through controlled paper consumption.

Choosing the Right Roll Type for Your Needs

Selecting between perforated roll and non-perforated roll depends on your specific application and convenience needs. Perforated rolls offer easy tearing and portion control, ideal for projects requiring frequent division, while non-perforated rolls provide uninterrupted material for continuous use or larger tasks. Assessing your usage frequency and cut precision helps determine the most efficient roll type to optimize your workflow.

Conclusion: Which Roll is Best for You?

Choosing between a perforated roll and a non-perforated roll depends on your specific application needs, ease of use, and waste management preferences. Perforated rolls provide convenience through pre-cut sections, reducing waste and improving handling efficiency in industries like packaging and food service. Non-perforated rolls offer flexibility for custom lengths and continuous use, making them ideal for specialized tasks requiring variable measurements or continuous material flow.

Perforated roll vs non-perforated roll Infographic

libmatt.com

libmatt.com