The felt side of paper features a softer, smoother texture due to contact with a felt belt during manufacturing, making it ideal for high-quality printing and writing. Your choice between the felt side and wire side depends on your need for texture and print finish, with the wire side offering a rougher, more fibrous surface.

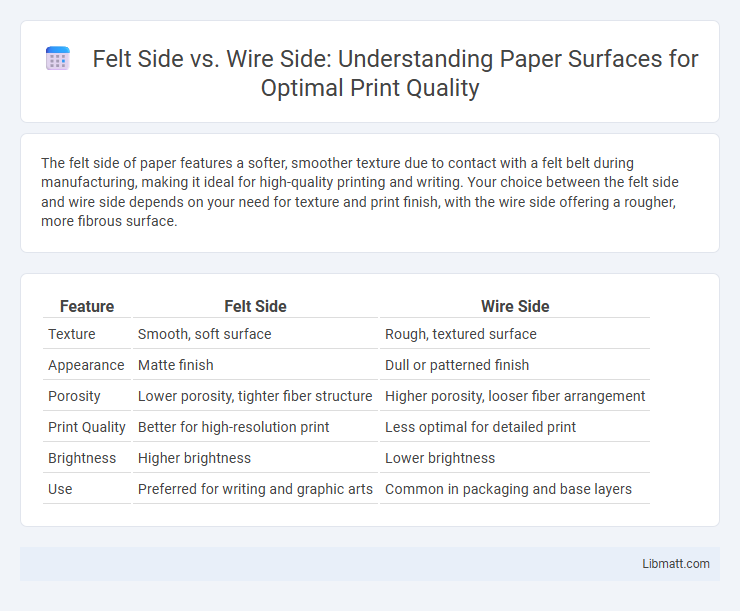

Table of Comparison

| Feature | Felt Side | Wire Side |

|---|---|---|

| Texture | Smooth, soft surface | Rough, textured surface |

| Appearance | Matte finish | Dull or patterned finish |

| Porosity | Lower porosity, tighter fiber structure | Higher porosity, looser fiber arrangement |

| Print Quality | Better for high-resolution print | Less optimal for detailed print |

| Brightness | Higher brightness | Lower brightness |

| Use | Preferred for writing and graphic arts | Common in packaging and base layers |

Introduction to Paper Surfaces: Felt Side vs Wire Side

Felt side and wire side represent the two distinct surfaces of paper produced on a Fourdrinier machine, each with unique texture and properties. The felt side, formed against the smooth felt fabric, exhibits a softer and more uniform appearance, ideal for high-quality printing and writing applications. In contrast, the wire side, contacting the wire mesh, is rougher and more textured, often influencing ink absorption and print clarity in different ways.

Understanding Papermaking: How Sides Are Formed

Felt side and wire side in papermaking refer to the two distinct surfaces of paper formed during the sheet formation process on the wire mesh and felt. The wire side, in direct contact with the wire mesh, typically exhibits a rougher texture and more fibrillation due to fiber orientation and drainage patterns. The felt side, molded against the smoother felt fabric, results in a smoother, more refined surface that often accepts printing and coatings better.

The Distinguishing Characteristics of Felt Side

The felt side of paper is characterized by a smoother, softer texture caused by the cushioning effect of the fabric during the papermaking process, resulting in a more uniform surface ideal for high-quality printing and writing. This side typically exhibits fewer surface irregularities, enhanced ink absorption, and a matte finish, distinguishing it from the wire side's rougher, more textured appearance. Your choice of the felt side can improve print clarity and tactile experience in applications where surface consistency matters.

Unique Features of Wire Side

The wire side of paper features a textured surface created by direct contact with the papermaking wire, resulting in a more pronounced, grid-like pattern compared to the smoother felt side. This distinct texture enhances print adhesion and ink absorption, making the wire side ideal for certain printing techniques that benefit from increased surface grip. Additionally, the wire side typically displays greater porosity, contributing to faster drying times and improved ink setting in specialized paper applications.

Visual and Textural Differences Between Felt and Wire Sides

The felt side of paper exhibits a smooth, soft texture and a matte finish, enhancing print clarity and tactile appeal, while the wire side is rougher with a more irregular surface that often shows subtle patterns from the wire mesh used during paper formation. Visual differences include the felt side's uniform appearance and the wire side's coarser, more fibrous look, which can affect ink absorption and print quality. Understanding these distinctions helps you choose the best surface for specific printing or artistic applications, ensuring optimal visual impact and texture.

Printing Implications: Which Side to Use?

Choosing the correct side for printing between felt side and wire side is essential for optimal print quality, as the felt side offers a smoother, more uniform surface ideal for sharp image reproduction and vibrant colors. The wire side, with its rougher texture and slight irregularities, may cause ink absorption inconsistencies, leading to less precise prints and potential smudging. For your printing projects, selecting the felt side ensures better ink adhesion and clarity, particularly in high-resolution or detailed designs.

Applications in Art and Design

Felt side and wire side paper surfaces offer distinct textures crucial for art and design applications, affecting paint absorption and detail rendering. The felt side is smooth and soft, ideal for watercolor washes and delicate ink drawings, while the wire side is rougher, providing greater tooth for charcoal, pastel, and mixed media techniques. Selecting the appropriate paper side enhances Your artistic expression by optimizing texture interaction and medium adherence in various creative projects.

Impact on Ink Absorption and Print Quality

The felt side of paper, characterized by its smoother and denser fibers, significantly enhances ink absorption, resulting in sharper images and richer color saturation. In contrast, the wire side typically exhibits a rougher texture with less uniform fiber distribution, which can cause uneven ink spread and reduced print clarity. Selecting the felt side for printing applications is crucial for achieving superior print quality, especially in high-resolution processes like offset and digital printing.

Choosing the Right Side for Your Project

Choosing the right paper side, felt side or wire side, is crucial for achieving the desired texture and finish in your project. The felt side, smoother and more absorbent, is ideal for printing and writing where clarity and ink adherence matter most, while the wire side offers a rougher texture that can enhance artistic effects or add grip. Consider the end-use requirements such as print quality, durability, and tactile experience to determine which surface best suits your project's needs.

Conclusion: Making the Most of Paper Surfaces

Felt side and wire side paper surfaces each offer distinct tactile and visual qualities essential for various printing and finishing applications. The felt side features a smoother, softer texture ideal for high-quality image reproduction, while the wire side provides a rougher, more textured finish suited for enhanced ink adhesion and durability. Understanding these characteristics allows printers and designers to optimize material selection, ensuring the best performance, aesthetic appeal, and functionality for specific paper-based projects.

Felt side vs wire side (paper surfaces) Infographic

libmatt.com

libmatt.com