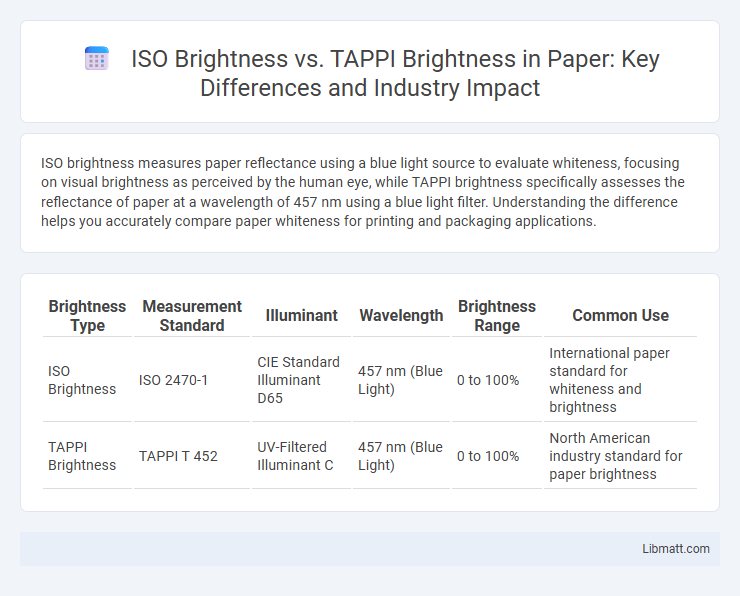

ISO brightness measures paper reflectance using a blue light source to evaluate whiteness, focusing on visual brightness as perceived by the human eye, while TAPPI brightness specifically assesses the reflectance of paper at a wavelength of 457 nm using a blue light filter. Understanding the difference helps you accurately compare paper whiteness for printing and packaging applications.

Table of Comparison

| Brightness Type | Measurement Standard | Illuminant | Wavelength | Brightness Range | Common Use |

|---|---|---|---|---|---|

| ISO Brightness | ISO 2470-1 | CIE Standard Illuminant D65 | 457 nm (Blue Light) | 0 to 100% | International paper standard for whiteness and brightness |

| TAPPI Brightness | TAPPI T 452 | UV-Filtered Illuminant C | 457 nm (Blue Light) | 0 to 100% | North American industry standard for paper brightness |

Introduction to Paper Brightness Standards

ISO brightness measures the reflectance of blue light at 457 nm, representing the paper's perceived whiteness under standardized lighting conditions. TAPPI brightness assesses reflectance at 457 nm as well but uses a different calibration standard, leading to slightly higher brightness values compared to ISO. Understanding these differences is crucial for accurately comparing paper brightness across industries and ensuring consistent quality control.

Defining ISO Brightness

ISO brightness measures the reflectance of a paper surface using a blue light source at 457 nm wavelength, standardized by the International Organization for Standardization (ISO 2470-1). This metric indicates how much light is reflected from the paper to quantify its whiteness and visual luminosity. Understanding ISO brightness helps You evaluate paper quality in applications requiring consistent optical properties compared to TAPPI brightness, which is measured at a different wavelength and standard (TAPPI T452).

What is TAPPI Brightness?

TAPPI Brightness measures the reflectance of a paper surface in blue light at a wavelength of 457 nanometers, indicating how much blue light is reflected by the sheet. It is a key quality parameter in the paper industry used to assess whiteness and visual brightness according to TAPPI standard T452. Compared to ISO brightness, TAPPI brightness values are slightly lower due to differences in measurement methods and light sources used.

Measurement Methods: ISO vs TAPPI

ISO brightness measures the reflectance of blue light at a wavelength of 457 nm using an angle of 45 degrees from the paper surface, providing higher comparability across different types of paper. TAPPI brightness also assesses reflectance but uses a wavelength of 457 nm with more specific instrument calibration focused on pulp and paper products, often yielding slightly different brightness values due to varied illumination and detector specifications. The distinction in measurement geometry and reference standards between ISO 2470 and TAPPI T452 leads to subtle differences critical for quality control in paper manufacturing and converting industries.

Spectral Differences in ISO and TAPPI Brightness

ISO brightness measures reflectance using blue light at 457 nm, emphasizing the cyan spectral region, whereas TAPPI brightness is assessed using a narrower band of blue light at 457 nm with an emphasis on the blue spectral region around 457 nm. The spectral differences result in ISO brightness capturing more reflectance from fluorescent whitening agents absorbing UV light below 400 nm, leading to higher brightness values compared to TAPPI. These distinctions impact the interpretation of brightness in paper and pulp industries, affecting quality control and optical property assessments.

Geographic Preference: ISO vs TAPPI

ISO brightness measurements are predominantly used in Europe and Asia, reflecting international standards preferred in these regions. TAPPI brightness is favored mainly in North America, aligning with industry practices in the United States and Canada. Your choice between ISO and TAPPI brightness standards may depend on the geographic location of your paper suppliers or markets.

Impact on Paper Appearance and Quality

ISO brightness measures the reflectance of blue light at 457 nm, resulting in a higher value that emphasizes whiteness and brightness, which directly influences the perceived cleanliness and vibrancy of your paper. TAPPI brightness, assessed at 449 nm, tends to yield slightly lower values and reflects a more traditional standard focused on common printing and copying requirements, affecting the uniformity and contrast of the printed images. The difference in measurement wavelengths means ISO brightness typically correlates with a cooler, bluish tone, while TAPPI brightness aligns with a warmer appearance, impacting the visual quality and market acceptance of your paper products.

Applications in Industry: When to Use Each Standard

ISO brightness measures the reflectance of blue light at 457 nm, commonly used in the paper industry for assessing paper whiteness in graphic arts and printing applications. TAPPI brightness evaluates reflectance at 457 nm as well but with different measurement geometry, making it suitable for pulp and paper manufacturers focusing on bleaching and quality control processes. Your choice between ISO and TAPPI brightness depends on whether you need standardization for end-use printing quality (ISO) or internal process control in pulp production (TAPPI).

Common Misconceptions About Paper Brightness

ISO brightness measures the reflectance of a blue light at 457 nm wavelength, whereas TAPPI brightness assesses reflectance specifically at 457 nm with different calibration standards. A common misconception is that these two brightness values can be used interchangeably; however, the ISO method often results in higher brightness readings due to its calibration against a magnesium oxide standard instead of barium sulfate used in TAPPI. Understanding these measurement nuances is crucial for accurate paper quality assessment and avoiding errors in specifying brightness levels.

Conclusion: Choosing the Right Brightness Standard

ISO brightness measures the reflectance of blue light at 457 nm wavelength, while TAPPI brightness evaluates reflectance at 457 nm but under a different test method and illumination conditions, leading to slightly different values. Your choice between ISO and TAPPI brightness depends on the specific industry standards and quality control requirements, with ISO often preferred for international consistency and TAPPI for paper industry benchmarks. Ensuring alignment with your target market or production specifications guarantees accurate brightness assessment and product quality.

ISO brightness vs TAPPI brightness Infographic

libmatt.com

libmatt.com