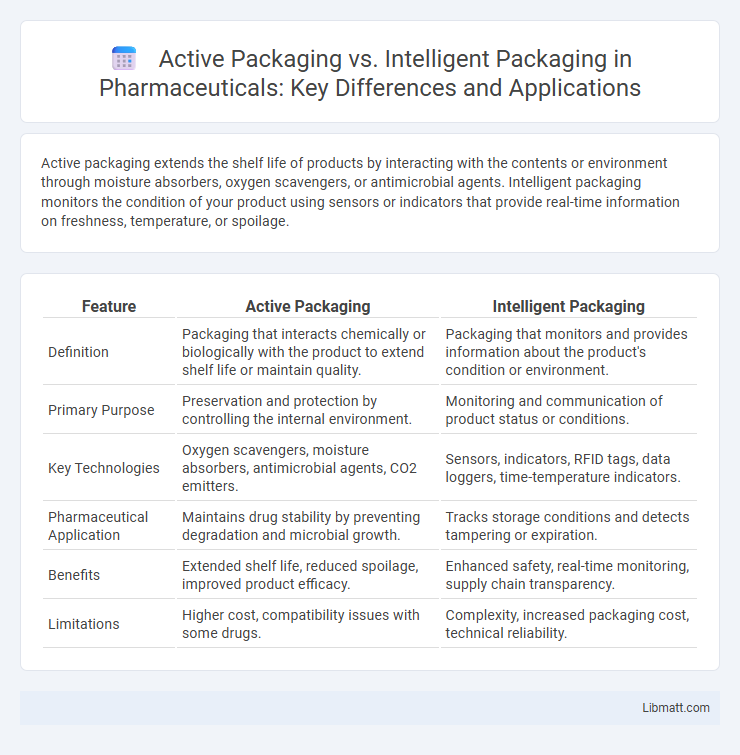

Active packaging extends the shelf life of products by interacting with the contents or environment through moisture absorbers, oxygen scavengers, or antimicrobial agents. Intelligent packaging monitors the condition of your product using sensors or indicators that provide real-time information on freshness, temperature, or spoilage.

Table of Comparison

| Feature | Active Packaging | Intelligent Packaging |

|---|---|---|

| Definition | Packaging that interacts chemically or biologically with the product to extend shelf life or maintain quality. | Packaging that monitors and provides information about the product's condition or environment. |

| Primary Purpose | Preservation and protection by controlling the internal environment. | Monitoring and communication of product status or conditions. |

| Key Technologies | Oxygen scavengers, moisture absorbers, antimicrobial agents, CO2 emitters. | Sensors, indicators, RFID tags, data loggers, time-temperature indicators. |

| Pharmaceutical Application | Maintains drug stability by preventing degradation and microbial growth. | Tracks storage conditions and detects tampering or expiration. |

| Benefits | Extended shelf life, reduced spoilage, improved product efficacy. | Enhanced safety, real-time monitoring, supply chain transparency. |

| Limitations | Higher cost, compatibility issues with some drugs. | Complexity, increased packaging cost, technical reliability. |

Introduction to Active and Intelligent Packaging

Active packaging involves materials designed to interact with the packaged product to extend shelf life, such as oxygen scavengers or moisture absorbers. Intelligent packaging incorporates sensors or indicators that monitor the condition of the product, providing real-time information about freshness, temperature, or contamination. Both technologies enhance food safety and quality but serve distinct roles in preservation and monitoring throughout the supply chain.

Defining Active Packaging

Active packaging actively interacts with the contents or environment to extend shelf life and maintain product quality by incorporating components like oxygen scavengers or moisture absorbers. It differs from intelligent packaging, which monitors and provides information about the condition of the product without altering the environment. Understanding active packaging helps you choose the right solution for enhancing freshness and safety in food or pharmaceutical products.

Understanding Intelligent Packaging

Intelligent packaging integrates sensors and indicators to monitor product condition, such as temperature, freshness, and tampering, enhancing consumer safety and supply chain transparency. Unlike active packaging, which interacts chemically or biologically to extend shelf life, intelligent packaging provides real-time data without altering the product environment. This technology leverages RFID tags, time-temperature indicators, and biosensors to deliver precise information, supporting quality assurance and reducing food waste.

Key Differences Between Active and Intelligent Packaging

Active packaging interacts directly with the product or its environment to extend shelf life or maintain quality by releasing or absorbing substances, whereas intelligent packaging monitors the condition of the product or environment and provides information about its status. Key differences include active packaging's role in altering product conditions through moisture control, oxygen scavenging, or antimicrobial agents, while intelligent packaging uses sensors, indicators, and RFID tags to track freshness, temperature, or tampering. The core distinction lies in active packaging's functional intervention versus intelligent packaging's information-providing capabilities.

Benefits of Active Packaging in Food Preservation

Active packaging enhances food preservation by actively interacting with the contents to extend shelf life, control moisture, and prevent microbial growth. It uses components like oxygen scavengers, moisture absorbers, and antimicrobial agents that protect freshness and maintain product quality. Your food remains safer and fresher longer, reducing waste and improving consumer satisfaction.

Advantages of Intelligent Packaging in Supply Chain Management

Intelligent packaging enhances supply chain management by providing real-time monitoring of product conditions such as temperature, humidity, and freshness, ensuring quality control and reducing spoilage. Advanced sensors and RFID technologies enable precise tracking and improved inventory management, leading to optimized logistics and reduced waste. This data-driven approach strengthens transparency and accountability throughout the supply chain, facilitating faster response to disruptions and more accurate demand forecasting.

Applications of Active Packaging in Various Industries

Active packaging is widely used in the food industry to extend shelf life by controlling moisture, oxygen, and microbial growth, thereby preserving freshness and safety. In the pharmaceutical sector, it enhances product stability and efficacy by protecting medications from environmental factors such as humidity and contamination. Your choice of active packaging can significantly improve product quality and consumer satisfaction across these industries.

Innovative Technologies in Intelligent Packaging

Innovative technologies in intelligent packaging include sensors, RFID tags, and time-temperature indicators that monitor product conditions in real-time, ensuring freshness and safety. Unlike active packaging, which interacts directly with the product to extend shelf life by releasing or absorbing substances, intelligent packaging provides critical data to you about the status of the product without altering it. These advancements enhance supply chain transparency and consumer trust through precise condition tracking and communication.

Challenges and Limitations of Each Packaging Type

Active packaging faces challenges such as potential chemical interactions with food products, limited shelf-life extension capabilities, and higher production costs. Intelligent packaging often encounters limitations including complexity in technology integration, dependency on sensor accuracy, and increased cost that can hinder widespread adoption. Both packaging types require careful consideration of environmental impact and regulatory compliance to ensure safety and sustainability.

Future Trends in Active and Intelligent Packaging

Future trends in active and intelligent packaging emphasize sustainability and advanced sensor integration to enhance product freshness and safety. Innovations in biodegradable materials and real-time monitoring technologies will empower your supply chain with improved traceability and waste reduction. These developments are set to revolutionize packaging by combining proactive preservation methods with smart data insights.

Active packaging vs Intelligent packaging Infographic

libmatt.com

libmatt.com