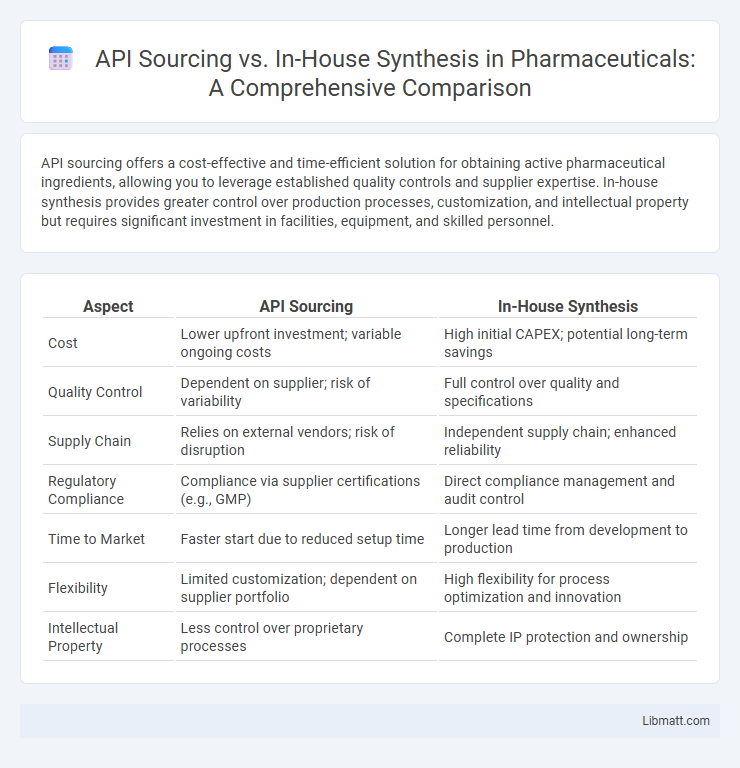

API sourcing offers a cost-effective and time-efficient solution for obtaining active pharmaceutical ingredients, allowing you to leverage established quality controls and supplier expertise. In-house synthesis provides greater control over production processes, customization, and intellectual property but requires significant investment in facilities, equipment, and skilled personnel.

Table of Comparison

| Aspect | API Sourcing | In-House Synthesis |

|---|---|---|

| Cost | Lower upfront investment; variable ongoing costs | High initial CAPEX; potential long-term savings |

| Quality Control | Dependent on supplier; risk of variability | Full control over quality and specifications |

| Supply Chain | Relies on external vendors; risk of disruption | Independent supply chain; enhanced reliability |

| Regulatory Compliance | Compliance via supplier certifications (e.g., GMP) | Direct compliance management and audit control |

| Time to Market | Faster start due to reduced setup time | Longer lead time from development to production |

| Flexibility | Limited customization; dependent on supplier portfolio | High flexibility for process optimization and innovation |

| Intellectual Property | Less control over proprietary processes | Complete IP protection and ownership |

Introduction to API Sourcing and In-House Synthesis

API sourcing involves procuring active pharmaceutical ingredients from external specialized manufacturers, ensuring access to high-quality substances without the need for extensive internal production facilities. In-house synthesis, on the other hand, enables pharmaceutical companies to maintain greater control over the manufacturing process, quality standards, and intellectual property by producing APIs within their own laboratories or plants. Your choice between these methods depends on factors such as cost efficiency, scalability, regulatory compliance, and strategic control over API development.

Defining API Sourcing: Process and Key Players

API sourcing involves procuring active pharmaceutical ingredients from external suppliers, streamlining drug manufacturing by leveraging specialized manufacturers. Key players in API sourcing include contract manufacturing organizations (CMOs), regulatory bodies ensuring compliance, and pharmaceutical companies prioritizing cost efficiency and quality assurance. This process emphasizes supplier evaluation, quality control, and adherence to international standards such as GMP to ensure reliable API supply chains.

Understanding In-House Synthesis: Capabilities and Resources

In-house synthesis requires specialized capabilities including advanced laboratory equipment, skilled chemists, and rigorous quality control protocols to produce active pharmaceutical ingredients (APIs) efficiently. Your organization must invest in state-of-the-art technology and maintain compliance with regulatory standards to ensure consistent product quality and scalability. This approach offers greater control over production timelines and customization but demands significant resource allocation and expertise.

Cost Comparison: API Sourcing vs. In-House Production

API sourcing often offers lower upfront costs by leveraging established manufacturing facilities and economies of scale, reducing capital expenditure on equipment and infrastructure. In-house synthesis entails higher initial investment due to the need for dedicated laboratories, skilled personnel, and quality control systems, but it allows greater control over production timelines and customization. Long-term cost efficiency depends on production volume, with API sourcing favored for small to medium batches, while in-house synthesis becomes economical at high volumes due to reduced per-unit costs.

Quality Control and Regulatory Compliance

API sourcing ensures consistent quality control through established supplier audits and compliance with international regulatory standards like GMP and FDA. In-house synthesis offers direct oversight of production processes, enabling customized quality checks but requires significant investment to meet stringent regulatory requirements. Balancing regulatory compliance and quality control in API sourcing often reduces risk and accelerates market entry compared to the complexities of maintaining in-house synthesis.

Speed to Market: Efficiency and Time Considerations

API sourcing significantly reduces speed to market by leveraging established suppliers with streamlined production processes and regulatory compliance, enabling faster delivery of active pharmaceutical ingredients. In-house synthesis often involves extensive development, optimization, and validation phases, which extend timelines but offer greater control over quality and supply chain. Strategic evaluation of project timelines and critical milestones determines whether the expedited efficiency of API sourcing or the customized control of in-house synthesis best aligns with market entry goals.

Intellectual Property and Confidentiality Concerns

API sourcing offers enhanced protection of intellectual property and confidentiality by allowing you to rely on specialized manufacturers with secure processes and strict compliance protocols. In-house synthesis may expose proprietary formulations and sensitive data to greater risk due to internal handling and potential employee turnover. Choosing external API sourcing reduces the likelihood of IP leakage and safeguards your confidential information through contractual agreements and dedicated security measures.

Scalability and Flexibility in API Supply

API sourcing offers superior scalability by leveraging external manufacturers' established production capacities, enabling rapid adaptation to market demand fluctuations. In-house synthesis provides greater flexibility in process customization and quality control but may face limitations in scaling operations quickly due to fixed facility resources. Strategic integration of both approaches can optimize supply chain resilience and responsiveness in active pharmaceutical ingredient production.

Risk Management: Supply Chain vs. Operational Risks

API sourcing involves managing supply chain risks such as supplier reliability, quality consistency, and geopolitical disruptions that can delay production and increase costs. In-house synthesis focuses on operational risks, including equipment failure, workforce expertise, and process control, which directly impact production efficiency and product quality. Your choice should balance these risk profiles to ensure steady supply and maintain manufacturing integrity.

Choosing the Right Approach: Factors to Consider

Evaluating factors such as cost efficiency, production scale, regulatory compliance, and time-to-market is crucial when choosing between API sourcing and in-house synthesis. API sourcing often offers faster access to high-quality active pharmaceutical ingredients with established supply chains, while in-house synthesis provides greater control over production processes and customization. Considerations around intellectual property protection, quality assurance, and logistical capabilities further influence the optimal strategy for pharmaceutical manufacturing.

API sourcing vs In-house synthesis Infographic

libmatt.com

libmatt.com