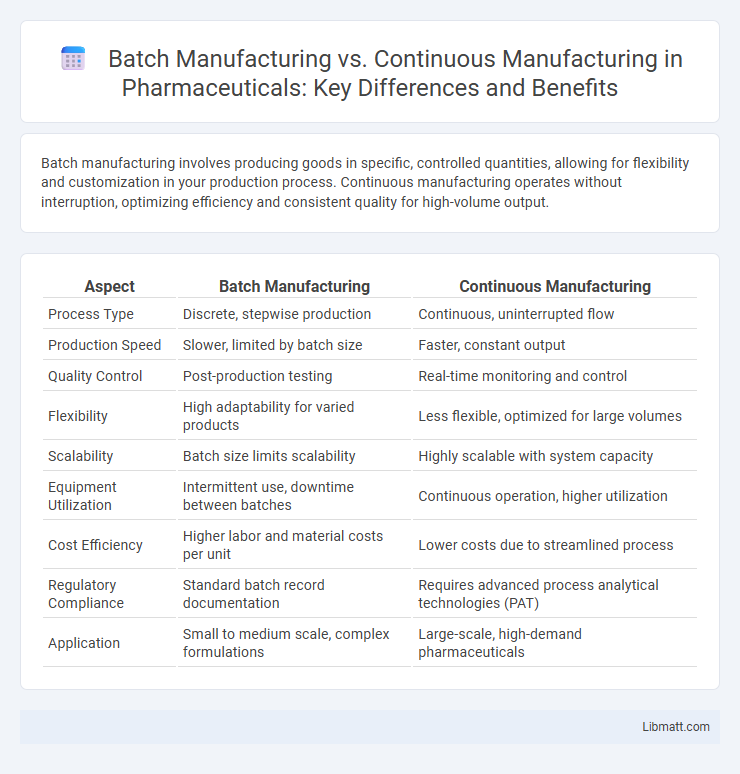

Batch manufacturing involves producing goods in specific, controlled quantities, allowing for flexibility and customization in your production process. Continuous manufacturing operates without interruption, optimizing efficiency and consistent quality for high-volume output.

Table of Comparison

| Aspect | Batch Manufacturing | Continuous Manufacturing |

|---|---|---|

| Process Type | Discrete, stepwise production | Continuous, uninterrupted flow |

| Production Speed | Slower, limited by batch size | Faster, constant output |

| Quality Control | Post-production testing | Real-time monitoring and control |

| Flexibility | High adaptability for varied products | Less flexible, optimized for large volumes |

| Scalability | Batch size limits scalability | Highly scalable with system capacity |

| Equipment Utilization | Intermittent use, downtime between batches | Continuous operation, higher utilization |

| Cost Efficiency | Higher labor and material costs per unit | Lower costs due to streamlined process |

| Regulatory Compliance | Standard batch record documentation | Requires advanced process analytical technologies (PAT) |

| Application | Small to medium scale, complex formulations | Large-scale, high-demand pharmaceuticals |

Introduction to Batch and Continuous Manufacturing

Batch manufacturing produces products in specific, discrete quantities, allowing flexibility for varied or custom orders. Continuous manufacturing operates non-stop, producing large volumes of standardized products with consistent quality and efficiency. Both methods play crucial roles in industries ranging from pharmaceuticals to food processing, balancing production speed and customization.

Key Differences Between Batch and Continuous Manufacturing

Batch manufacturing produces goods in specific quantities or batches, allowing flexibility in product variation and easier quality control for each batch. Continuous manufacturing operates non-stop with a steady flow of materials, enhancing efficiency and reducing downtime but offering less adaptability for product changes. The key differences lie in production scale, process control, and responsiveness, with batch favoring customization and continuous prioritizing volume and consistency.

Advantages of Batch Manufacturing

Batch manufacturing offers superior flexibility in producing diverse product variations, allowing manufacturers to quickly adjust recipes and scales for different batches. It enables precise quality control by isolating production runs, reducing the risk of widespread defects and facilitating easier troubleshooting. This method also supports lower initial capital investment compared to continuous manufacturing, making it ideal for small to medium-scale production and rapid response to market demand changes.

Advantages of Continuous Manufacturing

Continuous manufacturing offers significant advantages including consistent product quality, increased production efficiency, and reduced operational costs. This process minimizes downtime by operating 24/7, allowing for faster response to market demand and improved scalability compared to batch manufacturing. Your production line benefits from streamlined workflows and enhanced real-time monitoring, resulting in higher overall throughput and reliability.

Industries Suited for Batch Manufacturing

Batch manufacturing is ideal for pharmaceutical production, specialty chemicals, and food and beverage industries where product variation and customization are essential. This method supports industries requiring strict quality control and frequent product changeovers to meet diverse customer specifications. It effectively manages smaller production volumes and complex formulations compared to continuous manufacturing.

Industries Favoring Continuous Manufacturing

Pharmaceutical, chemical, and food industries favor continuous manufacturing due to its ability to enhance production efficiency, reduce waste, and maintain consistent product quality. Continuous manufacturing supports real-time monitoring and automated adjustments, crucial for meeting stringent regulatory standards in these sectors. The method enables higher scalability and faster response to market demand compared to batch processing.

Cost Implications and Operational Efficiency

Batch manufacturing often incurs higher costs due to frequent changeovers, setup times, and increased labor, impacting overall operational efficiency. Continuous manufacturing reduces downtime and material waste by maintaining constant production flow, leading to lower production costs and improved scalability. Your choice between the two methods should consider product complexity and volume demands to optimize cost-effectiveness and efficiency.

Quality Control and Flexibility Comparison

Batch manufacturing offers greater flexibility, allowing you to adjust production volumes and formulations between batches, which is ideal for custom or varied product lines, whereas continuous manufacturing provides consistent quality through steady-state processes, minimizing variability and defects. Quality control in batch manufacturing relies on batch-by-batch testing, potentially leading to variability, while continuous manufacturing integrates real-time monitoring and automated controls to ensure uniform output and rapid detection of deviations. Your choice depends on the priority between adaptability in product variation (batch) and precise, constant quality with higher efficiency (continuous).

Environmental Impact of Manufacturing Methods

Batch manufacturing generates more waste and energy consumption due to frequent start-stop cycles and cleaning processes, leading to higher environmental footprints. Continuous manufacturing operates with steady-state production, enhancing resource efficiency, reducing emissions, and minimizing waste generation. Industries adopting continuous manufacturing benefit from lower carbon emissions and decreased water usage, supporting sustainable manufacturing goals.

Choosing the Right Manufacturing Process

Choosing the right manufacturing process depends on your product volume, complexity, and flexibility requirements. Batch manufacturing offers adaptability for producing varied products in discrete quantities, ideal for customized orders or small-scale production. Continuous manufacturing excels in high-volume, consistent output with lower per-unit costs, making it suitable for mass production and streamlined operations.

Batch Manufacturing vs Continuous Manufacturing Infographic

libmatt.com

libmatt.com