Mesh size refers to the number of openings per inch in a screen or sieve, determining the size of particles that can pass through, while particle size is the actual diameter or dimension of individual particles. Understanding the relationship between mesh size and particle size helps you select the appropriate sieve for accurate separation and classification in various industrial or laboratory processes.

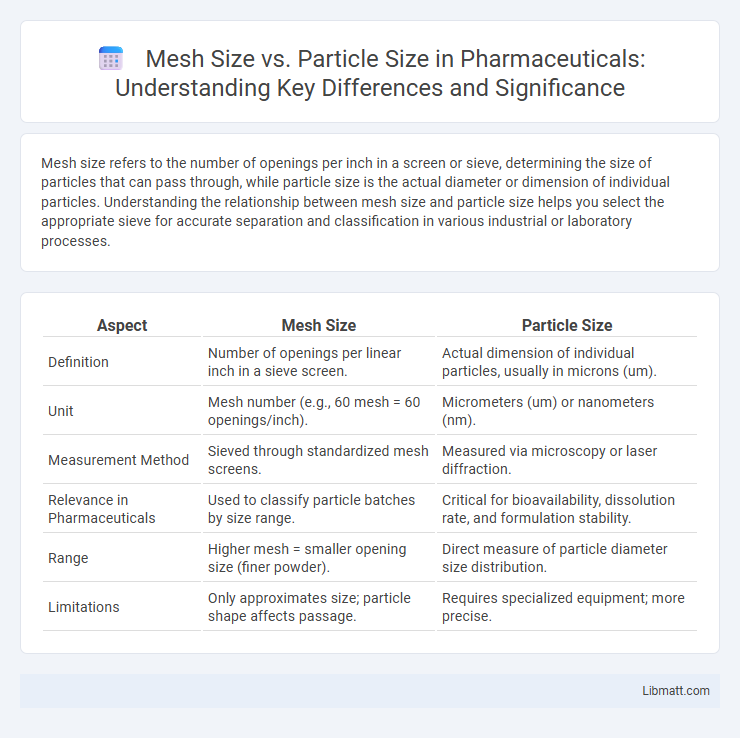

Table of Comparison

| Aspect | Mesh Size | Particle Size |

|---|---|---|

| Definition | Number of openings per linear inch in a sieve screen. | Actual dimension of individual particles, usually in microns (um). |

| Unit | Mesh number (e.g., 60 mesh = 60 openings/inch). | Micrometers (um) or nanometers (nm). |

| Measurement Method | Sieved through standardized mesh screens. | Measured via microscopy or laser diffraction. |

| Relevance in Pharmaceuticals | Used to classify particle batches by size range. | Critical for bioavailability, dissolution rate, and formulation stability. |

| Range | Higher mesh = smaller opening size (finer powder). | Direct measure of particle diameter size distribution. |

| Limitations | Only approximates size; particle shape affects passage. | Requires specialized equipment; more precise. |

Introduction to Mesh Size and Particle Size

Mesh size refers to the number of openings per linear inch in a screen, determining the size of particles that can pass through it. Particle size indicates the actual diameter or dimension of individual particles in a material, often measured in microns or millimeters. Understanding the relationship between mesh size and particle size helps you accurately select or analyze materials for filtration, sieving, and quality control.

Understanding Mesh Size: Definition and Significance

Mesh size refers to the number of openings per linear inch in a screen or sieve used to classify particles by size. It determines the particle size range that passes through, with higher mesh numbers indicating finer particles and smaller openings. Understanding mesh size is crucial in industries such as pharmaceuticals, mining, and agriculture to ensure precise particle size distribution for quality control and process efficiency.

What Is Particle Size? Importance and Measurement

Particle size refers to the diameter or dimensions of individual particles within a material, often measured in microns or millimeters. It is crucial in industries like pharmaceuticals, agriculture, and mining, as it affects product quality, solubility, and reaction rates. Particle size is commonly measured using techniques such as sieving, laser diffraction, and microscopy to ensure precise control over manufacturing processes.

Mesh Size vs Particle Size: Key Differences

Mesh size refers to the number of openings per linear inch in a screen or sieve, directly influencing the size of particles that can pass through it. Particle size denotes the actual diameter or dimension of individual particles, often measured in microns or millimeters, which determines their ability to pass through a given mesh. The key difference lies in mesh size being a standardized screen specification, while particle size is a physical property of the material, essential for applications requiring precise filtration or separation.

How Mesh Size Impacts Particle Size Distribution

Mesh size directly determines the particle size distribution by controlling the maximum particle diameter that can pass through a sieve. A smaller mesh size corresponds to finer openings, resulting in a narrower distribution with smaller particles, while a larger mesh size allows larger particles to pass, leading to a broader particle size range. Consistent mesh size selection is crucial in industries like pharmaceuticals, agriculture, and construction to achieve desired material properties and performance.

Methods for Measuring Mesh and Particle Sizes

Mesh size is determined using standard sieving techniques where particles pass through a mesh screen with uniform openings measured in microns or mesh count per inch. Particle size measurement methods include laser diffraction, dynamic light scattering, and microscopy imaging, which provide detailed size distribution and shape characteristics beyond simple mesh analysis. Combining sieving with advanced particle size analyzers ensures accurate assessment for quality control in industries like pharmaceuticals and mining.

Industry Applications: Choosing the Right Mesh and Particle Size

Selecting the appropriate mesh size and particle size is crucial across industries such as pharmaceuticals, mining, and food processing to ensure product quality and process efficiency. Finer mesh sizes allow for better separation and consistency in powders, while coarser meshes facilitate faster filtration or screening in bulk materials. Optimizing these parameters reduces waste, improves product uniformity, and enhances equipment performance in industrial applications.

Common Mesh Size Standards and Conversions

Common mesh size standards, such as U.S. Standard Sieve Series and ASTM E11, define the number of openings per linear inch, directly correlating with particle size retention capabilities. Mesh size conversions enable translating mesh number into microns or millimeters, facilitating precise particle size measurement and comparison across different testing methods. Accurate understanding of mesh size versus particle size is critical in industries like pharmaceuticals, mining, and agriculture for consistent material classification and quality control.

Factors Influencing Mesh and Particle Size Selection

Mesh size and particle size selection depend on factors such as material type, desired filtration or separation efficiency, and the specific application requirements. The particle size distribution of your sample directly influences the mesh size needed to achieve accurate sieving or filtering, ensuring optimal processing and quality control. Equipment capacity and environmental conditions also play crucial roles in determining the appropriate mesh and particle size combination.

Conclusion: Optimizing Processes with Proper Mesh and Particle Sizes

Optimizing processes with the proper mesh and particle sizes ensures efficient material separation, improved reaction rates, and enhanced product quality. Selecting the appropriate mesh size relative to particle size minimizes clogging and maximizes throughput, directly impacting operational efficiency. Your process will benefit from precise matching of mesh and particle parameters to achieve consistent results and reduce processing costs.

Mesh size vs particle size Infographic

libmatt.com

libmatt.com