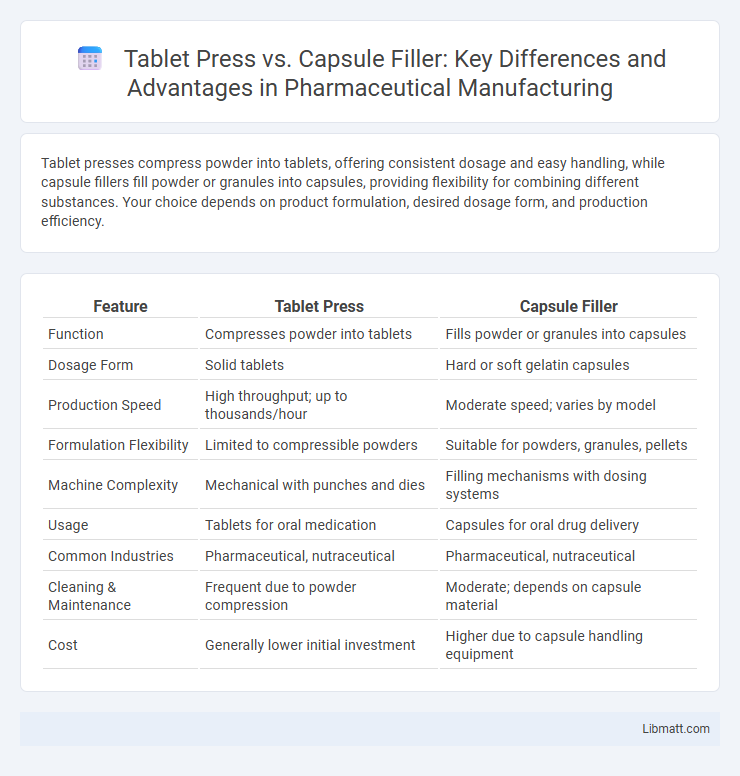

Tablet presses compress powder into tablets, offering consistent dosage and easy handling, while capsule fillers fill powder or granules into capsules, providing flexibility for combining different substances. Your choice depends on product formulation, desired dosage form, and production efficiency.

Table of Comparison

| Feature | Tablet Press | Capsule Filler |

|---|---|---|

| Function | Compresses powder into tablets | Fills powder or granules into capsules |

| Dosage Form | Solid tablets | Hard or soft gelatin capsules |

| Production Speed | High throughput; up to thousands/hour | Moderate speed; varies by model |

| Formulation Flexibility | Limited to compressible powders | Suitable for powders, granules, pellets |

| Machine Complexity | Mechanical with punches and dies | Filling mechanisms with dosing systems |

| Usage | Tablets for oral medication | Capsules for oral drug delivery |

| Common Industries | Pharmaceutical, nutraceutical | Pharmaceutical, nutraceutical |

| Cleaning & Maintenance | Frequent due to powder compression | Moderate; depends on capsule material |

| Cost | Generally lower initial investment | Higher due to capsule handling equipment |

Overview: Tablet Press vs Capsule Filler

Tablet presses compress powder into solid tablets, offering high-speed production with precise dosage control and consistent tablet weight. Capsule fillers automate the packing of powdered or granulated substances into capsules, ensuring uniform fill volume and flexibility for various capsule sizes. Both machines play critical roles in pharmaceutical manufacturing, with tablet presses suited for solid, compact dosing forms and capsule fillers ideal for encapsulating diverse formulations requiring protection from environmental exposure.

Core Functions and Mechanisms

Tablet presses compress powdered materials into solid tablets using precise punches and dies, ensuring uniform shape and dosage in pharmaceutical manufacturing. Capsule fillers automate the process of filling empty capsules with powders, granules, or liquids, maintaining product consistency and efficiency for encapsulated medications. Understanding these core mechanisms helps optimize your production line for either tablet or capsule formulation.

Key Differences in Operation

Tablet presses use compression force to form powdered materials into solid tablets, offering precise control over tablet weight and hardness, while capsule fillers deposit powders or pellets into preformed gelatin or vegetarian capsules with high speed and accuracy. Tablet presses typically require die and punch alignment for shaping tablets, whereas capsule fillers emphasize capsule size compatibility and filling mechanisms like tamping or dosator systems. Your choice depends on whether you need solid tablet dosage forms with uniform compaction or encapsulated powders that offer easier swallowing and customized release profiles.

Output and Production Efficiency

Tablet presses typically offer higher output rates, producing thousands of tablets per minute, making them ideal for large-scale pharmaceutical manufacturing. Capsule fillers generally operate at slower speeds due to the complexity of capsule encapsulation, with output ranging from hundreds to thousands of capsules per hour. Production efficiency in tablet presses benefits from quicker cycle times and easier automation, whereas capsule fillers often require more manual intervention, impacting overall throughput.

Suitability for Different Dosage Forms

Tablet presses are ideal for producing solid tablets from powdered or granulated ingredients, offering precise control over tablet size, shape, and dosage. Capsule fillers are better suited for filling powdered, granular, or liquid formulations into gelatin or vegetarian capsules, providing flexibility for sensitive or hygroscopic materials. Your choice depends on the dosage form, with tablet presses favoring compressed solids and capsule fillers accommodating diverse contents requiring encapsulation.

Material Compatibility and Flexibility

Tablet presses offer excellent material compatibility with powders and granules, making them ideal for compressing a wide range of substances into uniform tablets. Capsule fillers provide greater flexibility in filling various materials, including powders, pellets, and liquids, allowing customization of dosage forms. Your choice depends on whether you prioritize the consistent density of tablets or the versatile dosing options capsules provide.

Cost Analysis and Investment Considerations

Tablet presses typically require higher initial capital investment compared to capsule fillers due to their complex mechanical components and precision tooling. Operating costs for tablet presses include maintenance of punch and die sets, while capsule fillers involve lower parts wear and simpler changeover processes, reducing ongoing expenses. Businesses must weigh the volume requirements and product specifications to determine whether the higher upfront cost of tablet presses or the flexibility and lower maintenance costs of capsule fillers align better with their production goals.

Batch Size and Scalability

Tablet presses are ideal for large batch production, offering high scalability with the ability to produce thousands of tablets per minute, making them suitable for commercial manufacturing. Capsule fillers excel in small to medium batch sizes, providing flexibility for customized formulations but limited scalability compared to tablet presses. Understanding your batch size requirements is crucial in selecting the right equipment to optimize production efficiency.

Maintenance and Technical Support

Tablet press machines require regular maintenance of punches, dies, and compression rollers to prevent wear and ensure consistent tablet quality, with technical support often specializing in mechanical adjustments and software calibration. Capsule fillers demand frequent cleaning and inspection of dosing units and sealing components to avoid contamination and maintain capsule integrity, while technical support primarily addresses hopper calibration and electronic feeding systems. Both industries offer specialized after-sales service, but the complexity of tablet press machinery typically necessitates more advanced technical expertise for troubleshooting and part replacements.

Choosing the Right Solution for Your Facility

Choosing the right solution for your facility depends on production volume, product type, and budget considerations. Tablet presses excel in producing high-dose, uniform tablets with precise weight control, ideal for large-scale pharmaceutical manufacturing. Capsule fillers offer flexibility for powders and granules, suitable for smaller batches and formulations requiring minimal compression.

Tablet Press vs Capsule Filler Infographic

libmatt.com

libmatt.com