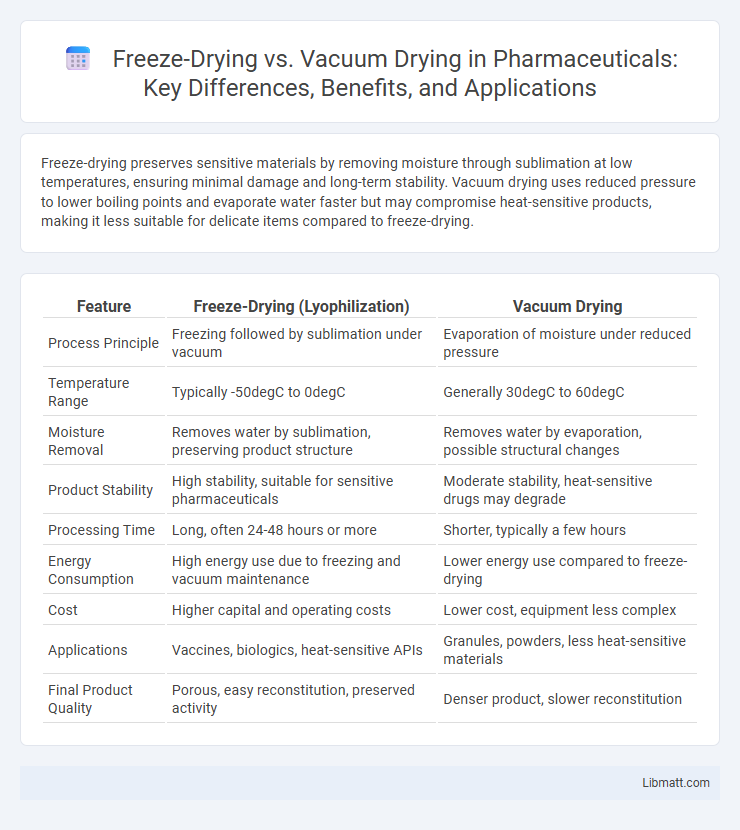

Freeze-drying preserves sensitive materials by removing moisture through sublimation at low temperatures, ensuring minimal damage and long-term stability. Vacuum drying uses reduced pressure to lower boiling points and evaporate water faster but may compromise heat-sensitive products, making it less suitable for delicate items compared to freeze-drying.

Table of Comparison

| Feature | Freeze-Drying (Lyophilization) | Vacuum Drying |

|---|---|---|

| Process Principle | Freezing followed by sublimation under vacuum | Evaporation of moisture under reduced pressure |

| Temperature Range | Typically -50degC to 0degC | Generally 30degC to 60degC |

| Moisture Removal | Removes water by sublimation, preserving product structure | Removes water by evaporation, possible structural changes |

| Product Stability | High stability, suitable for sensitive pharmaceuticals | Moderate stability, heat-sensitive drugs may degrade |

| Processing Time | Long, often 24-48 hours or more | Shorter, typically a few hours |

| Energy Consumption | High energy use due to freezing and vacuum maintenance | Lower energy use compared to freeze-drying |

| Cost | Higher capital and operating costs | Lower cost, equipment less complex |

| Applications | Vaccines, biologics, heat-sensitive APIs | Granules, powders, less heat-sensitive materials |

| Final Product Quality | Porous, easy reconstitution, preserved activity | Denser product, slower reconstitution |

Introduction to Freeze-Drying and Vacuum Drying

Freeze-drying, also known as lyophilization, removes moisture from materials by freezing and then applying a vacuum to sublimate ice directly into vapor, preserving the structure and nutrients. Vacuum drying involves lowering the pressure to reduce the boiling point of water, allowing drying at lower temperatures but without freezing, which can impact heat-sensitive products differently. Your choice between freeze-drying and vacuum drying depends on the sensitivity of the material and the desired quality of the final product.

Principles Behind Each Drying Method

Freeze-drying, or lyophilization, operates by freezing the material and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to vapor. Vacuum drying removes moisture by applying reduced pressure and gentle heat, causing water to evaporate at lower temperatures without freezing the product. Both methods rely on pressure manipulation, but freeze-drying uniquely preserves structure through sublimation, while vacuum drying emphasizes moisture removal via evaporation.

Key Equipment and Technology Used

Freeze-drying involves specialized equipment such as a freeze dryer or lyophilizer, which uses a vacuum chamber, refrigeration systems, and a condenser to sublimate ice directly from solid to vapor. Vacuum drying relies on vacuum ovens or vacuum dryers that reduce atmospheric pressure to lower the boiling point of water, enabling drying at lower temperatures without freezing. Your choice between these technologies depends on the precise control requirements and sensitivity of the material being processed.

Drying Process Overview: Step-by-Step

Freeze-drying begins with freezing the material, followed by placing it under a vacuum where sublimation allows ice to transition directly into vapor, preserving the product's structure and nutrients. Vacuum drying involves lowering the pressure to reduce the boiling point of water, enabling moisture to evaporate at lower temperatures, which helps maintain heat-sensitive qualities. Your choice between these methods depends on the specific drying goals, product sensitivity, and desired preservation of quality attributes.

Efficiency and Energy Consumption Comparison

Freeze-drying typically consumes more energy and requires longer processing times due to its low-temperature sublimation process, making it less energy-efficient compared to vacuum drying. Vacuum drying operates at higher temperatures and shorter cycles, reducing energy consumption while maintaining product quality for heat-sensitive materials. Your choice between freeze-drying and vacuum drying should consider the balance between energy efficiency and the desired preservation of product integrity.

Effects on Product Quality and Nutrient Retention

Freeze-drying preserves product quality and nutrient retention more effectively than vacuum drying by sublimating ice directly from the frozen state, which minimizes thermal degradation and maintains cellular structure. Vacuum drying, although conducted at lower pressures and temperatures than conventional drying, can still cause heat-sensitive nutrient loss and texture changes due to prolonged exposure to elevated temperatures. The preservation of bioactive compounds and flavor is significantly higher in freeze-dried products, making this method preferable for high-value food and pharmaceutical applications.

Applications in Food, Pharmaceuticals, and Biotechnology

Freeze-drying preserves the nutritional content and bioactivity of food, pharmaceuticals, and biotech products by removing moisture at low temperatures, making it ideal for heat-sensitive materials like vaccines and probiotics. Vacuum drying, offering faster dehydration at moderate temperatures, is commonly used for drying bulk food ingredients and pharmaceutical powders where rapid processing is prioritized over maximal preservation quality. Both technologies enhance shelf life and stability, but freeze-drying is preferred for maintaining structural integrity in delicate biologics and high-value nutraceuticals.

Cost Analysis and Economic Considerations

Freeze-drying typically incurs higher initial equipment and operational costs compared to vacuum drying due to the prolonged processing time and energy-intensive freezing phase. Vacuum drying offers reduced energy consumption and faster cycle times, translating to lower operational expenses and improved throughput. Evaluating long-term economic benefits involves considering product sensitivity, quality requirements, and volume, with freeze-drying favored for high-value, delicate products despite its higher cost.

Advantages and Limitations of Freeze-Drying

Freeze-drying offers the advantage of preserving the structural integrity and nutritional content of heat-sensitive products by removing moisture through sublimation at low temperatures, making it ideal for pharmaceuticals and food. Limitations include high operational costs, longer processing times, and the need for specialized equipment compared to vacuum drying. Your choice depends on the balance between product quality requirements and budget constraints.

Advantages and Limitations of Vacuum Drying

Vacuum drying offers faster drying times and lower temperature requirements compared to freeze-drying, making it suitable for heat-sensitive materials. It reduces oxidative degradation and preserves product quality but may not completely retain the original texture and nutritional content. Limitations include potential uneven drying and the need for careful control of vacuum pressure to prevent product collapse.

Freeze-drying vs vacuum drying Infographic

libmatt.com

libmatt.com