Tangential Flow Filtration (TFF) offers continuous filtration by flowing fluid tangentially across the membrane surface, reducing fouling and allowing high-volume processing, while Ultrafiltration/Diafiltration (UF/DF) focuses on separating molecules based on size and buffer exchange in batch mode. Your choice depends on processing scale and specific purification needs, as TFF is ideal for large volumes and UF/DF suits precise concentration and diafiltration steps.

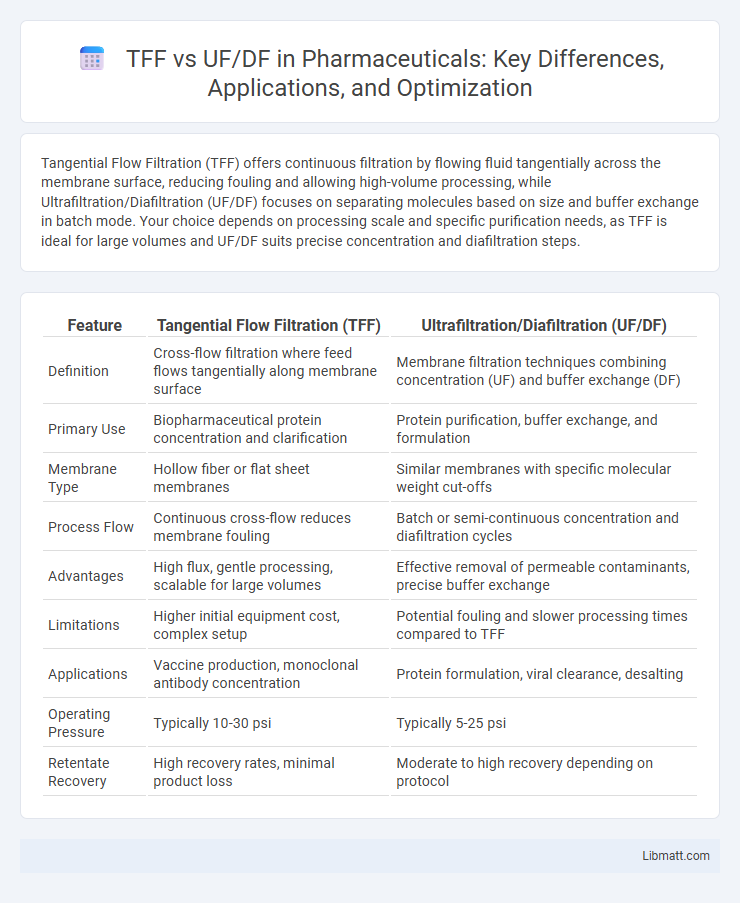

Table of Comparison

| Feature | Tangential Flow Filtration (TFF) | Ultrafiltration/Diafiltration (UF/DF) |

|---|---|---|

| Definition | Cross-flow filtration where feed flows tangentially along membrane surface | Membrane filtration techniques combining concentration (UF) and buffer exchange (DF) |

| Primary Use | Biopharmaceutical protein concentration and clarification | Protein purification, buffer exchange, and formulation |

| Membrane Type | Hollow fiber or flat sheet membranes | Similar membranes with specific molecular weight cut-offs |

| Process Flow | Continuous cross-flow reduces membrane fouling | Batch or semi-continuous concentration and diafiltration cycles |

| Advantages | High flux, gentle processing, scalable for large volumes | Effective removal of permeable contaminants, precise buffer exchange |

| Limitations | Higher initial equipment cost, complex setup | Potential fouling and slower processing times compared to TFF |

| Applications | Vaccine production, monoclonal antibody concentration | Protein formulation, viral clearance, desalting |

| Operating Pressure | Typically 10-30 psi | Typically 5-25 psi |

| Retentate Recovery | High recovery rates, minimal product loss | Moderate to high recovery depending on protocol |

Introduction to TFF and UF/DF

Tangential Flow Filtration (TFF) and Ultrafiltration/Diafiltration (UF/DF) are advanced membrane filtration techniques used in bioprocessing and pharmaceutical manufacturing. TFF operates by flowing the feed solution tangentially across the membrane surface, minimizing fouling and enabling continuous processing, while UF/DF primarily focuses on concentrating and diafiltering biomolecules by selective membrane separation. Your choice between TFF and UF/DF depends on specific operational goals, such as volume reduction, buffer exchange, or purification efficiency.

Principles of Tangential Flow Filtration (TFF)

Tangential Flow Filtration (TFF) operates by directing fluid flow parallel to the membrane surface, minimizing membrane fouling and allowing continuous processing of large volumes. Unlike Ultrafiltration/Diafiltration (UF/DF), which relies on perpendicular flow causing rapid membrane clogging, TFF maintains a steady shear force that enhances filtration efficiency and product recovery. Your filtration process benefits from TFF's ability to concentrate and diafilter biomolecules gently while preserving their structural integrity.

Understanding Ultrafiltration/Diafiltration (UF/DF)

Ultrafiltration/Diafiltration (UF/DF) is a membrane filtration process utilized primarily in biopharmaceutical manufacturing to concentrate and purify biomolecules. Ultrafiltration employs semipermeable membranes that selectively retain macromolecules such as proteins while allowing solvents and small solutes to pass through, enhancing product concentration. Diafiltration complements ultrafiltration by continuously exchanging the buffer solution, effectively removing impurities and enabling precise formulation adjustments.

Key Differences Between TFF and UF/DF

Tangential Flow Filtration (TFF) and Ultrafiltration/Diafiltration (UF/DF) differ primarily in their operational flow and application focus. TFF uses a cross-flow technique that minimizes membrane fouling and increases filtration efficiency, ideal for large-scale biomolecule separation. UF/DF combines ultrafiltration for concentration and diafiltration for buffer exchange, making it essential for purification and formulation processes in biopharmaceutical manufacturing.

Applications of TFF in Bioprocessing

Tangential Flow Filtration (TFF) is widely used in bioprocessing for efficient concentration and diafiltration of biomolecules such as proteins, antibodies, and vaccines. TFF enables high-throughput processing with minimal shear stress, preserving the bioactivity and structural integrity of sensitive compounds. Its scalability and adaptability make TFF essential for virus removal, buffer exchange, and cell harvest clarification in drug development and large-scale manufacturing.

UF/DF in Downstream Processing

Ultrafiltration/Diafiltration (UF/DF) plays a crucial role in downstream processing by concentrating and diafiltering bioproducts, effectively removing impurities and exchanging buffers. Unlike Tangential Flow Filtration (TFF), UF/DF specifically targets molecular weight-based separation, enabling precise purification and formulation of therapeutic proteins. This technique enhances product quality and consistency by maintaining solute retention while efficiently eliminating smaller contaminants during bioprocessing.

Membrane Selection Criteria for TFF and UF/DF

Membrane selection criteria for Tangential Flow Filtration (TFF) and Ultrafiltration/Diafiltration (UF/DF) center on molecular weight cutoff (MWCO), chemical compatibility, and fouling resistance to optimize separation efficiency. TFF typically requires membranes with higher flux and shear tolerance to maintain crossflow velocity, whereas UF/DF membranes prioritize tight MWCO ranges tailored to concentrate or exchange macromolecules without compromising retention. Your choice should consider application-specific parameters such as solute size, process scalability, and cleaning protocols to ensure membrane durability and performance.

Advantages and Limitations of TFF versus UF/DF

Tangential Flow Filtration (TFF) offers superior scalability and higher flux rates compared to Ultrafiltration/Diafiltration (UF/DF), enabling efficient processing of large volumes with reduced fouling. UF/DF excels in precision buffer exchange and concentration for small to medium-scale operations but is limited by slower processing times and membrane clogging. TFF's cross-flow mechanism maintains consistent filtration performance, whereas UF/DF's dead-end filtration often necessitates frequent membrane cleaning and replacement.

Scale-Up Considerations for Each Technique

Tangential Flow Filtration (TFF) offers reliable scalability with consistent product quality and process control, making it ideal for larger volumes and industrial-scale applications. Ultrafiltration/Diafiltration (UF/DF) systems excel in scalability by allowing precise buffer exchange and concentration adjustments, but may require more frequent membrane replacement and cleaning during scale-up. Your choice depends on balancing cost efficiency, equipment footprint, and the specific requirements of your bioprocess.

Choosing Between TFF and UF/DF: Decision Factors

Choosing between Tangential Flow Filtration (TFF) and Ultrafiltration/Diafiltration (UF/DF) depends on factors such as feed volume, molecular weight cut-off, and process scalability. TFF is ideal for larger volumes and provides continuous operation with efficient concentration and diafiltration capabilities. Your selection should be guided by specific process requirements including product recovery rate, membrane type, and desired throughput.

TFF vs UF/DF Infographic

libmatt.com

libmatt.com