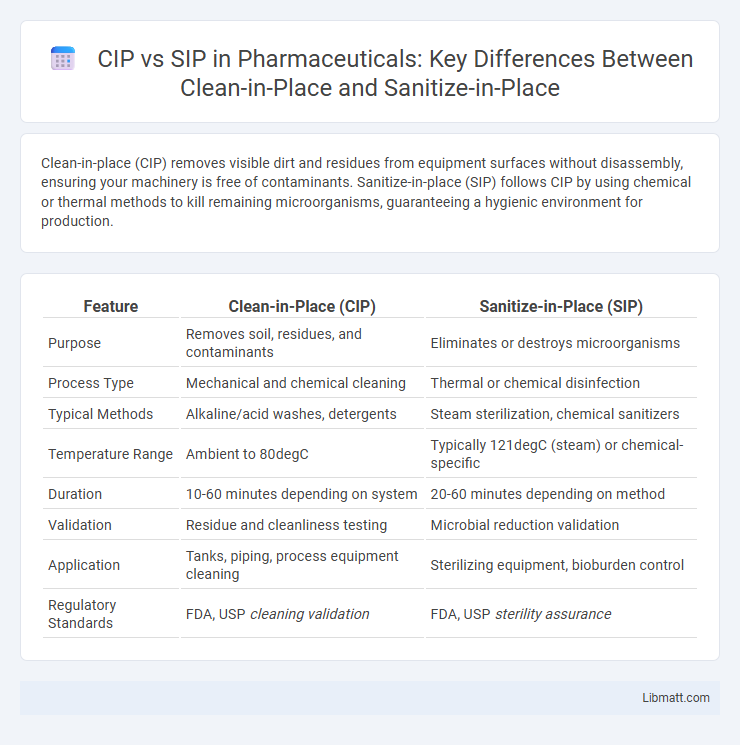

Clean-in-place (CIP) removes visible dirt and residues from equipment surfaces without disassembly, ensuring your machinery is free of contaminants. Sanitize-in-place (SIP) follows CIP by using chemical or thermal methods to kill remaining microorganisms, guaranteeing a hygienic environment for production.

Table of Comparison

| Feature | Clean-in-Place (CIP) | Sanitize-in-Place (SIP) |

|---|---|---|

| Purpose | Removes soil, residues, and contaminants | Eliminates or destroys microorganisms |

| Process Type | Mechanical and chemical cleaning | Thermal or chemical disinfection |

| Typical Methods | Alkaline/acid washes, detergents | Steam sterilization, chemical sanitizers |

| Temperature Range | Ambient to 80degC | Typically 121degC (steam) or chemical-specific |

| Duration | 10-60 minutes depending on system | 20-60 minutes depending on method |

| Validation | Residue and cleanliness testing | Microbial reduction validation |

| Application | Tanks, piping, process equipment cleaning | Sterilizing equipment, bioburden control |

| Regulatory Standards | FDA, USP cleaning validation | FDA, USP sterility assurance |

Introduction to CIP and SIP

Clean-in-place (CIP) and sanitize-in-place (SIP) are automated methods used in industries like food processing and pharmaceuticals to clean and sanitize equipment without disassembly. CIP focuses on removing residues, soils, and biofilms using detergents and water, while SIP involves applying chemical or thermal agents to eliminate microorganisms after CIP. Implementing CIP and SIP ensures your equipment meets hygiene standards efficiently, reducing downtime and contamination risks.

Key Differences Between CIP and SIP

Clean-in-place (CIP) focuses on the automated removal of soil and contaminants from equipment surfaces using detergents and water without disassembly, while Sanitize-in-place (SIP) employs chemical or thermal agents to reduce microbial populations to safe levels after cleaning. CIP primarily targets physical and chemical residues, whereas SIP specifically aims at microbial inactivation to ensure hygienic safety. The operational parameters such as temperature, chemical concentration, and exposure time differ significantly between CIP and SIP to meet their distinct sanitation goals.

How Clean-in-Place (CIP) Works

Clean-in-Place (CIP) works by circulating cleaning solutions such as detergents and water through equipment piping, vessels, and filters without disassembly, ensuring removal of residue and contaminants. The process involves predefined cycles including rinsing, washing, and final rinsing stages that are controlled automatically for thorough cleanliness. Your facility benefits from reduced downtime and consistent hygiene standards, making CIP essential for industries like food and pharmaceuticals.

How Sanitize-in-Place (SIP) Functions

Sanitize-in-Place (SIP) functions by applying heat and/or chemical agents to eliminate or reduce microbial contaminants on equipment surfaces without disassembly, ensuring microbial safety in production environments. This process typically involves circulating sanitizing solutions such as steam, hot water, or chemical sanitizers through the system under controlled parameters like temperature and contact time. SIP is essential in industries like pharmaceuticals and food processing, where sterile conditions are mandatory, and it complements Clean-in-Place (CIP) by focusing specifically on microbial inactivation rather than just soil removal.

Equipment and Systems Involved in CIP and SIP

Clean-in-place (CIP) systems involve equipment such as automated spray nozzles, pumps, valves, and piping designed to circulate cleaning solutions through processing lines without disassembly. Sanitize-in-place (SIP) typically incorporates steam generators, heat exchangers, and control units to apply sanitizing agents or steam at regulated temperatures, ensuring microbial safety. Your facility's choice between CIP and SIP depends on the compatibility of equipment materials and the specific hygiene requirements of the production process.

Applications of CIP in Various Industries

Clean-in-place (CIP) systems are widely utilized in industries such as food and beverage, pharmaceuticals, and dairy processing to efficiently clean internal surfaces of equipment without disassembly. These automated processes ensure removal of residues, microbial contaminants, and soil, maintaining hygiene standards crucial for product safety and compliance with regulatory guidelines like FDA and USDA. CIP applications enhance operational efficiency by reducing downtime and minimizing manual cleaning errors in breweries, juice production, and biotechnology manufacturing.

Applications of SIP Across Sectors

Sanitize-in-place (SIP) is widely applied in pharmaceutical manufacturing, food and beverage processing, and biotechnology industries to ensure sterile conditions without equipment disassembly. SIP technology effectively eliminates microbial contaminants within complex processing systems, minimizing downtime and maintaining product safety. Your operations benefit from SIP's compliance with stringent regulatory standards such as FDA and GMP, making it essential for high-purity and contamination-sensitive environments.

Advantages and Limitations of CIP

Clean-in-place (CIP) systems offer significant advantages such as reducing labor costs, minimizing equipment disassembly, and ensuring consistent cleaning quality in food and pharmaceutical industries. CIP limitations include high initial setup costs, potential for incomplete removal of biofilms if improperly designed, and reliance on chemical and water efficiency for optimal performance. Proper monitoring and validation are essential to overcome these constraints and maintain hygiene standards.

Benefits and Drawbacks of SIP

Sanitize-in-place (SIP) offers the significant benefit of eliminating microbial contaminants without disassembling equipment, reducing downtime and labor costs in food and pharmaceutical manufacturing. However, SIP's reliance on high temperatures or chemical agents can cause wear on sensitive components and may not remove physical residues as effectively as clean-in-place (CIP) methods. Your choice between SIP and CIP should balance the need for microbial safety with equipment durability and operational efficiency.

Choosing Between CIP and SIP: Factors to Consider

Choosing between Clean-in-Place (CIP) and Sanitize-in-Place (SIP) depends on the degree of microbial control and residue removal required in food and pharmaceutical processing. CIP systems are optimized for removing soil, biofilms, and product residues through automated cleaning cycles, reducing downtime and labor costs. SIP, involving sterilization often via steam or chemical agents, is essential for equipment requiring a high level of microbial inactivation to meet stringent hygiene standards.

Clean-in-place (CIP) vs sanitize-in-place (SIP) Infographic

libmatt.com

libmatt.com