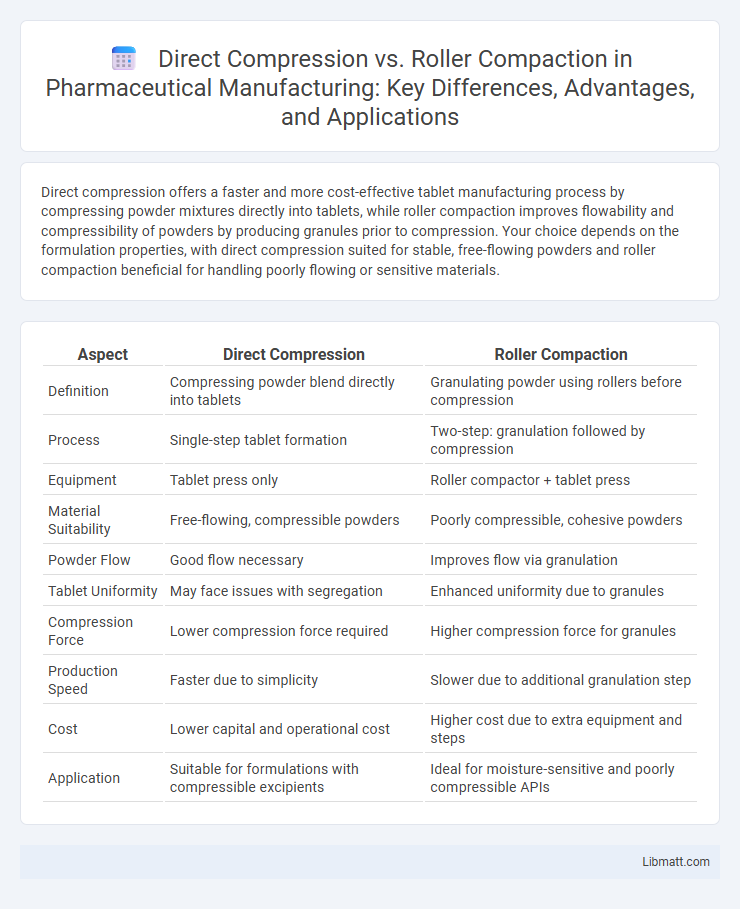

Direct compression offers a faster and more cost-effective tablet manufacturing process by compressing powder mixtures directly into tablets, while roller compaction improves flowability and compressibility of powders by producing granules prior to compression. Your choice depends on the formulation properties, with direct compression suited for stable, free-flowing powders and roller compaction beneficial for handling poorly flowing or sensitive materials.

Table of Comparison

| Aspect | Direct Compression | Roller Compaction |

|---|---|---|

| Definition | Compressing powder blend directly into tablets | Granulating powder using rollers before compression |

| Process | Single-step tablet formation | Two-step: granulation followed by compression |

| Equipment | Tablet press only | Roller compactor + tablet press |

| Material Suitability | Free-flowing, compressible powders | Poorly compressible, cohesive powders |

| Powder Flow | Good flow necessary | Improves flow via granulation |

| Tablet Uniformity | May face issues with segregation | Enhanced uniformity due to granules |

| Compression Force | Lower compression force required | Higher compression force for granules |

| Production Speed | Faster due to simplicity | Slower due to additional granulation step |

| Cost | Lower capital and operational cost | Higher cost due to extra equipment and steps |

| Application | Suitable for formulations with compressible excipients | Ideal for moisture-sensitive and poorly compressible APIs |

Introduction to Direct Compression and Roller Compaction

Direct compression is a widely used pharmaceutical tablet manufacturing process where powders are compressed directly into tablets without prior granulation, ensuring high efficiency and simplicity. Roller compaction, also known as dry granulation, involves compacting powders into ribbons or flakes using rollers, which are then milled into granules to improve flowability and compressibility. Both methods influence tablet properties, with direct compression favored for moisture-sensitive materials and roller compaction suited for formulations requiring improved powder handling characteristics.

Principles of Direct Compression

Direct compression relies on the ability of powders to flow and compress into tablets without the need for granulation, emphasizing excipients with good binding and flow properties such as microcrystalline cellulose and lactose. This method improves manufacturing efficiency by eliminating wet or dry granulation steps, reducing moisture exposure and processing time. Optimal particle size distribution and moisture content are critical to achieve uniform tablet weight and hardness in direct compression processes.

Fundamentals of Roller Compaction

Roller compaction is a dry granulation process that uses pressure to convert powder into dense ribbons or sheets, which are subsequently milled into granules. This method ensures improved flowability and compressibility of challenging powders without the need for moisture or high temperatures. Unlike direct compression, roller compaction offers enhanced control over particle size distribution and granule density, optimizing downstream tableting performance.

Key Differences Between Direct Compression and Roller Compaction

Direct Compression involves blending powder ingredients and compressing them into tablets without prior granulation, ideal for heat-sensitive or moisture-sensitive drugs. Roller Compaction, on the other hand, is a dry granulation process where powders are compacted into ribbons and then milled into granules, enhancing flowability and compressibility for formulations prone to poor flow. Understanding these key differences helps optimize your tablet manufacturing process based on drug properties and production efficiency.

Advantages of Direct Compression

Direct compression offers the advantage of a simpler manufacturing process, reducing production time and costs by eliminating granulation steps. It ensures superior content uniformity and tablet hardness due to direct powder compaction, enhancing overall product quality. This method also allows for better control over moisture-sensitive or heat-sensitive materials, preserving active pharmaceutical ingredients' stability.

Advantages of Roller Compaction

Roller compaction offers superior advantages for processing moisture-sensitive and heat-sensitive materials due to its dry granulation process, which eliminates the need for binders or solvents. This method enhances powder flowability and compressibility, resulting in uniform granules that improve tablet quality and reduce production variability. Your pharmaceutical manufacturing benefits from increased scalability, cost efficiency, and reduced dust generation compared to direct compression techniques.

Material Suitability and Formulation Considerations

Direct compression is ideal for materials with good flowability and compressibility, such as microcrystalline cellulose and lactose, enabling simple formulations without granulation. Roller compaction suits powders with poor flow properties or moisture sensitivity, allowing dry granulation to improve blend uniformity and compressibility for challenging active pharmaceutical ingredients (APIs). Formulation considerations include particle size distribution, moisture content, and API stability, which influence the choice between the two methods to ensure tablet quality and performance.

Process Equipment and Operational Steps

Direct compression uses a single-step process where powders are blended and directly compressed into tablets using a rotary tablet press, requiring minimal equipment such as a blender and tablet press. Roller compaction involves multiple operational steps including powder feeding, slugging by compaction between rollers on a roller compactor, milling the slugs into granules, and subsequent tablet compression, necessitating equipment like a roller compactor, mill, blender, and tablet press. The complexity of roller compaction equipment and steps allows processing of powders with poor flow or compressibility, unlike the simpler, faster direct compression method suited for free-flowing, compressible powders.

Common Challenges and Troubleshooting Strategies

Direct compression frequently contends with issues such as poor powder flow and segregation, demanding precise excipient selection and rigorous powder characterization to ensure uniformity. Roller compaction faces challenges including ribbon sticking and inconsistent compact density, which can be mitigated through optimization of roll pressure, speed, and granule moisture content. Troubleshooting strategies for both techniques emphasize real-time process monitoring, implementation of robust formulation modifications, and advanced PAT tools to maintain product quality and process efficiency.

Application Examples and Industry Trends

Direct compression is widely used in the pharmaceutical industry for producing tablets with heat-sensitive ingredients, such as vitamins and antibiotics, due to its minimal processing steps and cost efficiency. Roller compaction is preferred in industries requiring granulated materials, like detergents and food products, because it improves flowability and compressibility without the need for solvents. Your choice between these methods should consider current industry trends favoring continuous manufacturing and sustainability, where direct compression supports faster production and reduced energy consumption.

Direct Compression vs Roller Compaction Infographic

libmatt.com

libmatt.com