Laminar airflow features smooth, orderly fluid motion with parallel layers, minimizing friction and resistance, while turbulent airflow involves chaotic, irregular fluid movement that increases drag and energy loss. Understanding these differences can optimize your designs in aerodynamics, HVAC systems, and fluid dynamics applications.

Table of Comparison

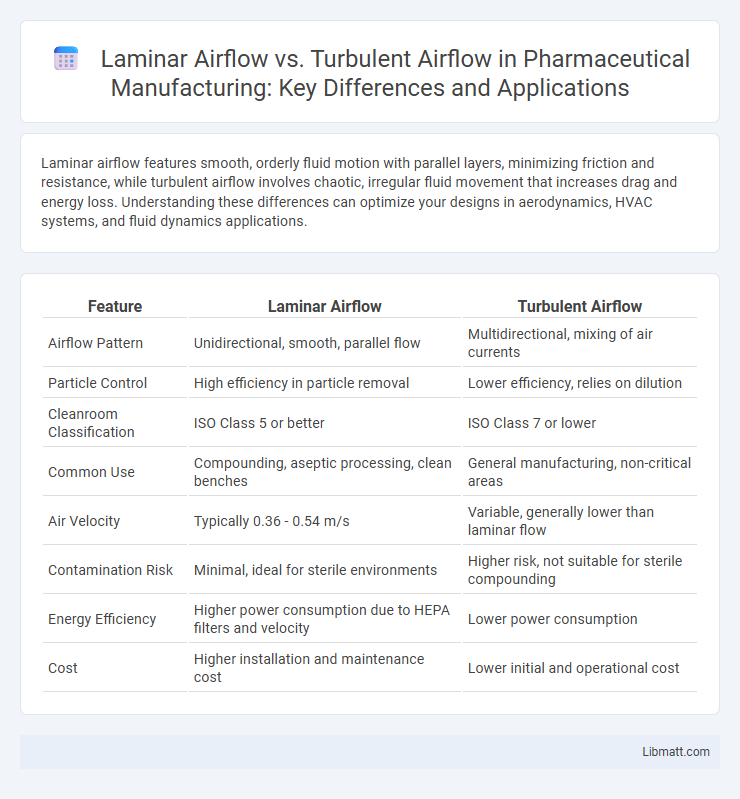

| Feature | Laminar Airflow | Turbulent Airflow |

|---|---|---|

| Airflow Pattern | Unidirectional, smooth, parallel flow | Multidirectional, mixing of air currents |

| Particle Control | High efficiency in particle removal | Lower efficiency, relies on dilution |

| Cleanroom Classification | ISO Class 5 or better | ISO Class 7 or lower |

| Common Use | Compounding, aseptic processing, clean benches | General manufacturing, non-critical areas |

| Air Velocity | Typically 0.36 - 0.54 m/s | Variable, generally lower than laminar flow |

| Contamination Risk | Minimal, ideal for sterile environments | Higher risk, not suitable for sterile compounding |

| Energy Efficiency | Higher power consumption due to HEPA filters and velocity | Lower power consumption |

| Cost | Higher installation and maintenance cost | Lower initial and operational cost |

Introduction to Airflow Dynamics

Laminar airflow is characterized by smooth, parallel layers of air moving uniformly, minimizing turbulence and particle disturbance, which is essential in cleanrooms and controlled environments. Turbulent airflow involves chaotic, irregular air movement that enhances mixing but increases contamination risk and energy consumption in ventilation systems. Understanding these airflow dynamics helps you select the optimal air distribution method for improved indoor air quality and system efficiency.

Understanding Laminar Airflow

Laminar airflow is characterized by smooth, parallel layers of air moving in a uniform direction, minimizing turbulence and particle dispersion. This airflow type is crucial in sterile environments like cleanrooms and operating theaters, where contamination control is essential. Maintaining laminar airflow reduces airborne pathogens and particulate matter, ensuring optimal air quality and safety standards.

Defining Turbulent Airflow

Turbulent airflow is characterized by chaotic and irregular fluid motion, resulting in eddies and vortices that disrupt smooth flow patterns. Unlike laminar airflow, which maintains parallel layers with minimal mixing, turbulent airflow enhances mixing and increases friction, impacting heat transfer and drag. Understanding turbulent airflow is crucial for optimizing designs in aerospace, HVAC, and industrial applications where fluid behavior affects performance and efficiency.

Key Differences Between Laminar and Turbulent Airflow

Laminar airflow features smooth, parallel layers of air moving in a consistent direction, resulting in minimal mixing and reduced friction, whereas turbulent airflow is characterized by chaotic, irregular air movements with eddies and vortices that increase mixing and drag. You experience laminar airflow in applications requiring precision and cleanliness, such as in cleanrooms and aerodynamic surface designs, while turbulent airflow is common in natural environments and situations demanding enhanced mixing, like combustion engines. Understanding these key differences helps optimize performance by selecting the appropriate airflow type for your specific needs in engineering and fluid dynamics.

Factors Influencing Airflow Patterns

Factors influencing airflow patterns include velocity, surface roughness, and fluid viscosity, which determine whether airflow remains laminar or becomes turbulent. Smooth, steady, and slower-moving air tends to maintain laminar flow, characterized by parallel layers, while increased speed, obstacles, or irregular surfaces promote chaotic, unpredictable turbulent flow. Reynolds number, a dimensionless value, quantifies these influences, with lower values indicating laminar conditions and higher values signaling turbulence.

Applications of Laminar Airflow

Laminar airflow provides a controlled, unidirectional flow of air that drastically reduces contamination, making it essential in environments like cleanrooms, pharmaceutical manufacturing, and operating theaters. Your work benefits from laminar airflow by ensuring particle-free air, which protects sensitive equipment and critical processes from airborne contaminants. This precise airflow control supports the production of high-quality sterile products and maintains compliance with stringent hygiene standards.

Applications of Turbulent Airflow

Turbulent airflow is widely used in applications requiring efficient mixing and heat transfer, such as combustion engines, HVAC systems, and industrial drying processes. Its chaotic flow enhances the rate of mass and energy exchange, making it ideal for mixing fuels with air in combustion chambers or dispersing temperature effectively in ventilation. Your systems benefit from turbulent airflow when rapid, uniform mixing is essential for optimal performance and energy efficiency.

Advantages and Disadvantages: Laminar vs Turbulent

Laminar airflow offers advantages such as smooth, predictable air movement that minimizes particle contamination and ensures precise control in cleanroom environments, but it can be less effective in mixing and dispersing pollutants. Turbulent airflow provides better air mixing and contaminant dilution, enhancing ventilation effectiveness but increasing the risk of cross-contamination due to irregular flow patterns. Your choice depends on specific needs for contamination control versus air distribution efficiency in applications like healthcare or manufacturing.

Impact on Energy Efficiency and System Performance

Laminar airflow systems maintain smooth, consistent air movement, minimizing friction and pressure drops, which enhances energy efficiency by reducing the load on HVAC components. Turbulent airflow, characterized by chaotic and irregular patterns, increases energy consumption due to greater resistance and mixing losses within ducts and ventilation systems. Optimizing your setup with laminar airflow can improve overall system performance, lowering operational costs and maintaining stable environmental conditions.

Choosing the Right Airflow for Your Application

Laminar airflow provides a uniform, unidirectional flow ideal for cleanrooms and environments requiring minimal particle contamination, ensuring consistent air quality and precise control. Turbulent airflow generates thorough mixing, suitable for general ventilation and industrial spaces where robust air distribution and dilution of contaminants are essential. Selecting between laminar and turbulent airflow depends on application-specific needs like contamination control, air velocity, and space configuration to optimize performance and safety.

Laminar airflow vs Turbulent airflow Infographic

libmatt.com

libmatt.com