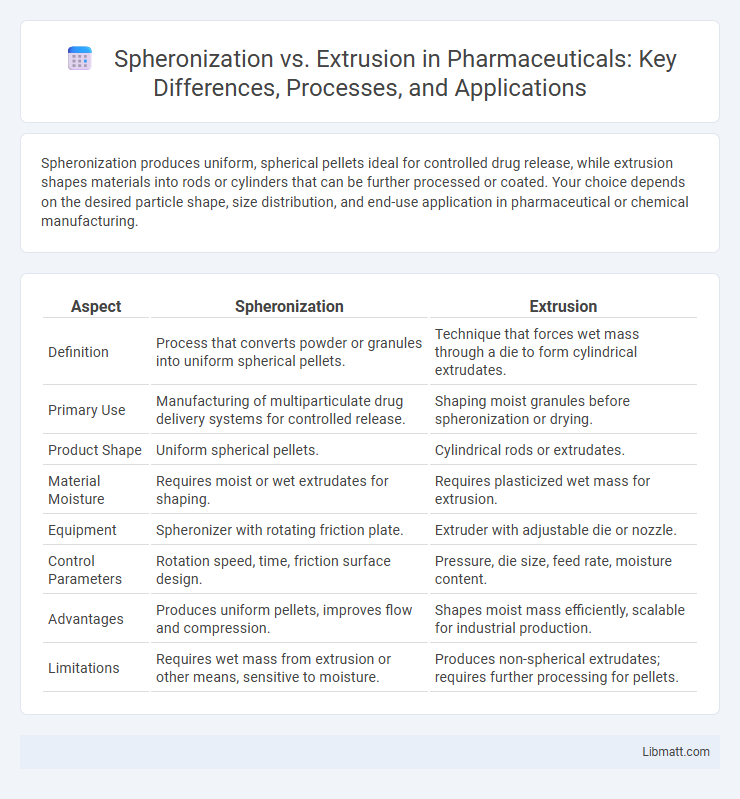

Spheronization produces uniform, spherical pellets ideal for controlled drug release, while extrusion shapes materials into rods or cylinders that can be further processed or coated. Your choice depends on the desired particle shape, size distribution, and end-use application in pharmaceutical or chemical manufacturing.

Table of Comparison

| Aspect | Spheronization | Extrusion |

|---|---|---|

| Definition | Process that converts powder or granules into uniform spherical pellets. | Technique that forces wet mass through a die to form cylindrical extrudates. |

| Primary Use | Manufacturing of multiparticulate drug delivery systems for controlled release. | Shaping moist granules before spheronization or drying. |

| Product Shape | Uniform spherical pellets. | Cylindrical rods or extrudates. |

| Material Moisture | Requires moist or wet extrudates for shaping. | Requires plasticized wet mass for extrusion. |

| Equipment | Spheronizer with rotating friction plate. | Extruder with adjustable die or nozzle. |

| Control Parameters | Rotation speed, time, friction surface design. | Pressure, die size, feed rate, moisture content. |

| Advantages | Produces uniform pellets, improves flow and compression. | Shapes moist mass efficiently, scalable for industrial production. |

| Limitations | Requires wet mass from extrusion or other means, sensitive to moisture. | Produces non-spherical extrudates; requires further processing for pellets. |

Introduction to Spheronization and Extrusion

Spheronization and extrusion are crucial techniques in pharmaceutical and chemical manufacturing for shaping granular materials into uniform particles. Spheronization transforms cylindrical extrudates into spherical pellets with enhanced flow and compaction properties, while extrusion forms continuous shapes by forcing material through a die under controlled pressure. Understanding these processes helps optimize particle size, shape, and density, improving your product's quality and performance.

Defining Spheronization: Process and Applications

Spheronization is a pharmaceutical process that transforms irregularly shaped particles into uniform, spherical pellets by rolling them on a rotating plate, enhancing flow properties and dosing accuracy. Widely applied in drug manufacturing, this technique optimizes controlled-release formulations and improves the bioavailability of active pharmaceutical ingredients. Your production efficiency benefits from spheronization when consistent pellet size and uniform drug distribution are critical.

Understanding Extrusion: Techniques and Uses

Extrusion is a manufacturing process where material is pushed through a shaped die to create continuous objects with uniform cross-sections, commonly used in producing pipes, films, and profiles. Techniques include hot extrusion, cold extrusion, and co-extrusion, each suited for different materials and applications ranging from plastics to metals. This method allows for high production efficiency, precise control over product dimensions, and versatility in producing complex shapes.

Key Differences Between Spheronization and Extrusion

Spheronization and extrusion are distinct pharmaceutical granulation techniques primarily differentiated by their end product shape and process mechanics. Extrusion involves forcing a wet mass through a die to form continuous rods or strands, which are then cut to desired lengths, while spheronization reshapes these extruded strands into uniform spherical pellets using a rotating plate or spheronizer. Key differences include extrusion's role in shaping and densifying material before sizing, compared to spheronization's function of refining particle shape for improved flow and coating properties in drug formulation.

Comparative Advantages of Spheronization

Spheronization offers superior uniformity in pellet size and shape compared to extrusion, enhancing drug release consistency and handling efficiency. This process improves flow properties and compaction behavior, making it ideal for controlled-release formulations. Its ability to produce spherical pellets reduces dust formation, promoting better content uniformity and product stability.

Benefits and Limitations of Extrusion

Extrusion offers precise control over product shape and size, making it ideal for creating uniform pellets or granules in pharmaceutical and food industries. Its continuous processing capability enhances production efficiency but requires significant energy and maintenance costs. Your choice to use extrusion should consider material properties, potential thermal degradation, and equipment investment.

Material Suitability for Spheronization vs Extrusion

Spheronization is ideal for materials with a plastic or semi-solid consistency that can be transformed into uniform spherical pellets, commonly used with moist powders, wet masses, or pastes like pharmaceuticals or fertilizers. Extrusion suits materials that are more malleable and plastically deformable, including granulated or powdered feeds blended with binders to form continuous rods or sheets before cutting, often applied in food processing and polymer shaping. The choice depends on the physical properties, moisture content, and desired particle shape, with spheronization favoring materials that pelletize well and extrusion accommodating a broader range of viscoelastic substances.

Equipment and Operational Requirements

Spheronization requires specialized equipment such as a spheronizer featuring a rotating plate for pellet formation, demanding precise control over moisture content and rotation speed to achieve uniform spherical granules. Extrusion utilizes an extruder apparatus where material is forced through a die under controlled temperature and pressure, requiring robust motors and cooling systems to maintain shape and prevent clogging. Both processes necessitate careful operational adjustments to optimize particle size and surface smoothness for pharmaceutical and food applications.

Quality Parameters and Product Characteristics

Spheronization produces uniform, spherical pellets with controlled size, excellent flowability, and consistent drug release profiles, ideal for multiparticulate delivery systems. Extrusion offers versatility in product shape and density, enabling tailored porosity and mechanical strength, which impacts dissolution rates and bioavailability. Your choice between these methods depends on desired product characteristics such as pellet uniformity, mechanical robustness, and release kinetics.

Choosing the Right Technique: Factors to Consider

Choosing between spheronization and extrusion depends on factors such as material properties, desired particle shape, and production scale. Spheronization excels in creating uniform, spherical pellets with high mechanical strength, ideal for controlled-release formulations, while extrusion is preferred for forming uniform strands from viscous or plasticized masses. Your selection should also consider equipment availability, process complexity, and specific application requirements to ensure optimal product performance.

Spheronization vs Extrusion Infographic

libmatt.com

libmatt.com