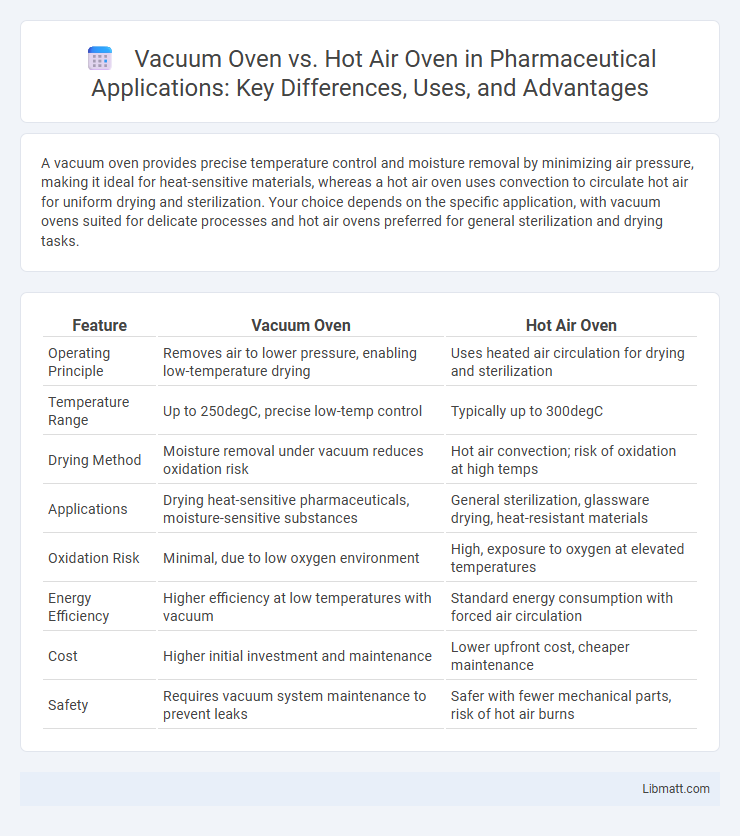

A vacuum oven provides precise temperature control and moisture removal by minimizing air pressure, making it ideal for heat-sensitive materials, whereas a hot air oven uses convection to circulate hot air for uniform drying and sterilization. Your choice depends on the specific application, with vacuum ovens suited for delicate processes and hot air ovens preferred for general sterilization and drying tasks.

Table of Comparison

| Feature | Vacuum Oven | Hot Air Oven |

|---|---|---|

| Operating Principle | Removes air to lower pressure, enabling low-temperature drying | Uses heated air circulation for drying and sterilization |

| Temperature Range | Up to 250degC, precise low-temp control | Typically up to 300degC |

| Drying Method | Moisture removal under vacuum reduces oxidation risk | Hot air convection; risk of oxidation at high temps |

| Applications | Drying heat-sensitive pharmaceuticals, moisture-sensitive substances | General sterilization, glassware drying, heat-resistant materials |

| Oxidation Risk | Minimal, due to low oxygen environment | High, exposure to oxygen at elevated temperatures |

| Energy Efficiency | Higher efficiency at low temperatures with vacuum | Standard energy consumption with forced air circulation |

| Cost | Higher initial investment and maintenance | Lower upfront cost, cheaper maintenance |

| Safety | Requires vacuum system maintenance to prevent leaks | Safer with fewer mechanical parts, risk of hot air burns |

Introduction: Vacuum Oven vs Hot Air Oven

Vacuum ovens operate by removing air and reducing pressure to enable low-temperature drying and curing, preserving sensitive materials and preventing oxidation. Hot air ovens use convection heating with circulating hot air to ensure uniform temperature distribution for sterilization and drying processes. Choosing between vacuum and hot air ovens depends on specific applications requiring controlled atmosphere or higher temperature durability.

How Vacuum Ovens Work

Vacuum ovens operate by removing air and other gases from the chamber, creating a low-pressure environment that reduces oxidation and contamination during the drying or curing process. This low-pressure setting lowers the boiling point of liquids, enabling faster drying at lower temperatures, which is essential for heat-sensitive materials. Their precise temperature control and vacuum system make them ideal for pharmaceutical, electronics, and chemical industries where preserving product integrity is critical.

How Hot Air Ovens Operate

Hot air ovens operate by circulating heated air uniformly throughout the chamber using a fan, ensuring consistent temperature distribution for effective drying and sterilization. The heating element warms the air, which is then pushed by the fan to maintain stable temperatures typically ranging from 50degC to 300degC. This convection process enables hot air ovens to remove moisture by evaporation, making them ideal for sterilizing metal instruments, glassware, and heat-resistant materials in laboratories and medical settings.

Key Differences Between Vacuum and Hot Air Ovens

Vacuum ovens operate under reduced pressure, enabling low-temperature drying and preventing oxidation while preserving sensitive materials. Hot air ovens use ambient atmospheric pressure with circulated heated air, achieving rapid drying and sterilization through higher temperatures. The key differences lie in their operational environment, temperature control, and suitability for heat-sensitive versus general-purpose applications.

Advantages of Using a Vacuum Oven

Vacuum ovens provide precise temperature control and reduced oxidation risk, ideal for sensitive materials and pharmaceutical applications. They enable faster drying times by lowering the boiling point of substances under reduced pressure, preserving material integrity. The controlled environment minimizes contamination and thermal degradation, enhancing product quality and consistency.

Benefits of Using a Hot Air Oven

Hot air ovens provide consistent and uniform heat distribution, making them ideal for sterilization and drying applications in medical and laboratory settings. Their ability to reach high temperatures quickly enhances efficiency in microbial and moisture removal processes. Furthermore, hot air ovens are cost-effective, easy to operate, and require less maintenance compared to vacuum ovens.

Applications of Vacuum Ovens

Vacuum ovens are ideal for drying heat-sensitive materials, removing solvents, and curing adhesives without oxidation or contamination, making them essential in pharmaceutical, electronics, and chemical laboratories. They provide a controlled atmosphere with reduced pressure, enabling gentle drying and preventing thermal degradation of materials. Your specific application benefits from their ability to maintain product integrity during processes that require precise temperature control and moisture removal.

Applications of Hot Air Ovens

Hot air ovens are commonly used for sterilizing medical instruments, glassware, and metal equipment through dry heat. Their applications extend to baking, curing, and heat treatment processes in laboratories and manufacturing industries. You can rely on hot air ovens for consistent drying and dehydration of samples without moisture contamination.

Factors to Consider When Choosing Between Vacuum and Hot Air Ovens

Selecting between vacuum ovens and hot air ovens depends on factors such as temperature sensitivity of materials, desired drying speed, and potential oxidation risks. Vacuum ovens are ideal for heat-sensitive substances requiring low-temperature drying without oxidation, whereas hot air ovens offer faster drying for less sensitive materials through forced convection. Consideration of product nature, processing atmosphere, and specific drying requirements is essential for optimal oven choice.

Conclusion: Which Oven is Best for Your Needs?

A vacuum oven is ideal for sensitive materials requiring low-temperature drying with minimal oxidation, making it perfect for pharmaceuticals, electronics, and delicate samples. A hot air oven suits applications needing high-temperature sterilization and reliable heat distribution, commonly used in laboratories and medical settings. Your choice depends on whether you prioritize moisture-free drying under controlled conditions (vacuum oven) or robust heating capabilities for sterilization (hot air oven).

Vacuum Oven vs Hot Air Oven Infographic

libmatt.com

libmatt.com