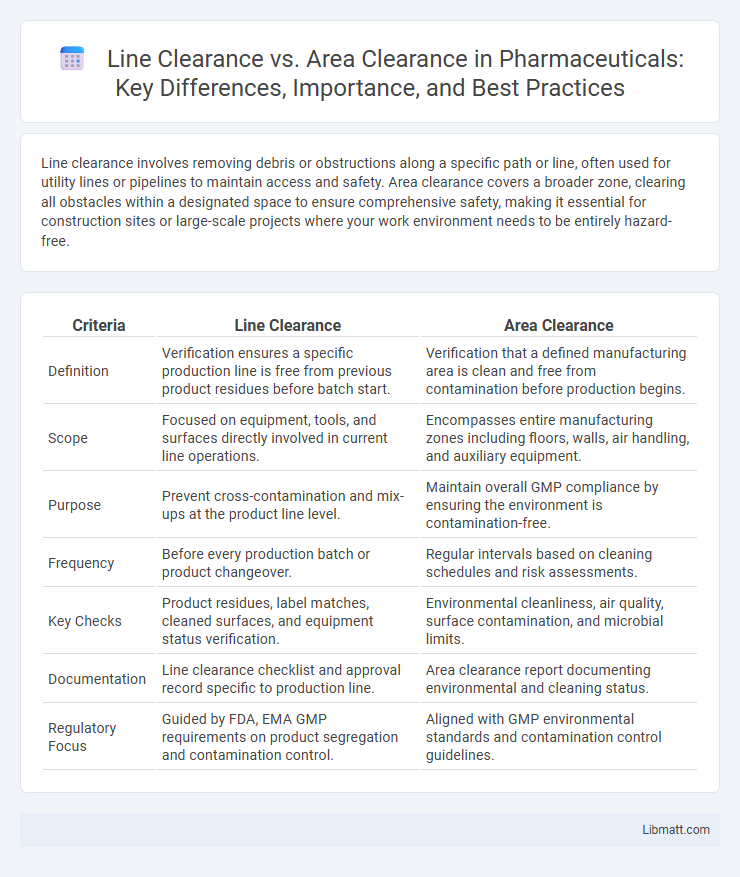

Line clearance involves removing debris or obstructions along a specific path or line, often used for utility lines or pipelines to maintain access and safety. Area clearance covers a broader zone, clearing all obstacles within a designated space to ensure comprehensive safety, making it essential for construction sites or large-scale projects where your work environment needs to be entirely hazard-free.

Table of Comparison

| Criteria | Line Clearance | Area Clearance |

|---|---|---|

| Definition | Verification ensures a specific production line is free from previous product residues before batch start. | Verification that a defined manufacturing area is clean and free from contamination before production begins. |

| Scope | Focused on equipment, tools, and surfaces directly involved in current line operations. | Encompasses entire manufacturing zones including floors, walls, air handling, and auxiliary equipment. |

| Purpose | Prevent cross-contamination and mix-ups at the product line level. | Maintain overall GMP compliance by ensuring the environment is contamination-free. |

| Frequency | Before every production batch or product changeover. | Regular intervals based on cleaning schedules and risk assessments. |

| Key Checks | Product residues, label matches, cleaned surfaces, and equipment status verification. | Environmental cleanliness, air quality, surface contamination, and microbial limits. |

| Documentation | Line clearance checklist and approval record specific to production line. | Area clearance report documenting environmental and cleaning status. |

| Regulatory Focus | Guided by FDA, EMA GMP requirements on product segregation and contamination control. | Aligned with GMP environmental standards and contamination control guidelines. |

Understanding Line Clearance and Area Clearance

Line clearance involves inspecting and removing contaminants from specific production lines or equipment to ensure product quality and prevent cross-contamination. Area clearance refers to the broader cleaning and verification of entire production areas or zones to maintain overall hygiene and compliance with industry standards. Both processes are critical in regulated environments such as pharmaceuticals and food processing to uphold safety and regulatory requirements.

Key Differences Between Line Clearance and Area Clearance

Line clearance involves inspecting and ensuring a specific production line is free from contaminants or previous product residues before a new production batch begins, while area clearance focuses on the broader validation of an entire production environment, such as a room or facility, to confirm cleanliness and absence of hazards. Key differences include the scope, as line clearance targets a defined piece of equipment or process, whereas area clearance covers larger physical spaces, impacting overall hygiene standards, contamination control, and regulatory compliance. Line clearance typically requires checklist verification of equipment setup and materials, whereas area clearance demands environmental monitoring and microbial testing to validate sterility or cleanliness levels.

Importance of Line Clearance in Manufacturing

Line clearance in manufacturing ensures the complete removal of materials, tools, and residues from production lines before starting a new batch, preventing contamination and cross-mixing. It is critical for maintaining product quality, adhering to strict regulatory compliance, and minimizing risks of recalls or production stoppages. Unlike area clearance, which cleans broader spaces, line clearance focuses specifically on the immediate production line, enhancing process accuracy and operational efficiency.

Benefits of Area Clearance Procedures

Area clearance procedures provide comprehensive protection by thoroughly checking a larger expanse of land for mines and unexploded ordnance, significantly reducing the risk of accidental detonations. These methods enhance safety for communities by enabling safe access to entire fields, roads, and residential zones rather than just narrow pathways. Your safety is ensured through systematic clearance, which supports long-term land rehabilitation and promotes economic development in previously hazardous areas.

Regulatory Requirements for Line and Area Clearance

Regulatory requirements for line clearance mandate the removal of flammable vegetation and debris along utility lines to prevent fire hazards, often specified by agencies like OSHA and NFPA. Area clearance involves clearing larger zones around structures or facilities to create defensible spaces, adhering to local fire codes and environmental regulations. Your compliance with these standards ensures safety and reduces wildfire risks in both linear corridors and broader property areas.

Step-by-Step Line Clearance Process

The Step-by-Step Line Clearance Process involves verifying that each work area is free from any previous batch materials to prevent cross-contamination and ensure product integrity. It starts with removing all items unrelated to the current production batch, followed by thorough cleaning and inspection of equipment and surfaces against standardized checklists. Final documentation includes signatures from responsible personnel to confirm that the line is ready for the new production run.

Area Clearance: Best Practices and Guidelines

Area clearance involves systematically inspecting and securing an entire location to detect and remove hazardous materials or threats, following strict safety protocols to protect personnel and property. Best practices include conducting thorough risk assessments, using trained personnel with appropriate detection equipment, and documenting all findings and actions for accountability. Your adherence to these guidelines ensures comprehensive threat mitigation and enhances overall site safety during clearance operations.

Common Challenges in Line vs Area Clearance

Line clearance often faces the challenge of detecting specific contaminants along a narrow focus area, requiring precise inspection and verification methods. Area clearance must address broader surface coverage, which increases the complexity of identifying residual particles across larger and more varied environments. Your choice between line and area clearance depends on balancing thoroughness with operational efficiency in contamination control.

Technologies Enhancing Clearance Procedures

Line clearance techniques leverage advanced drone imaging and GPS mapping technologies to precisely identify and remove vegetation along power lines, ensuring safety and reducing downtime. Area clearance benefits from satellite data and AI-powered vegetation analytics, enabling thorough assessment and systematic trimming over large geographic zones. Integration of LiDAR and thermal imaging further enhances accuracy and efficiency in both clearance methods, minimizing human error and environmental impact.

Choosing the Right Clearance Method for Your Facility

Selecting the appropriate clearance method for your facility depends on factors such as the size of the contamination, space configuration, and operational requirements. Line clearance targets specific production lines or equipment for swift, localized decontamination, ideal for facilities with defined contamination zones. Area clearance involves comprehensive cleaning of larger zones, ensuring thorough decontamination for environments with widespread contamination or strict regulatory compliance needs.

Line clearance vs Area clearance Infographic

libmatt.com

libmatt.com