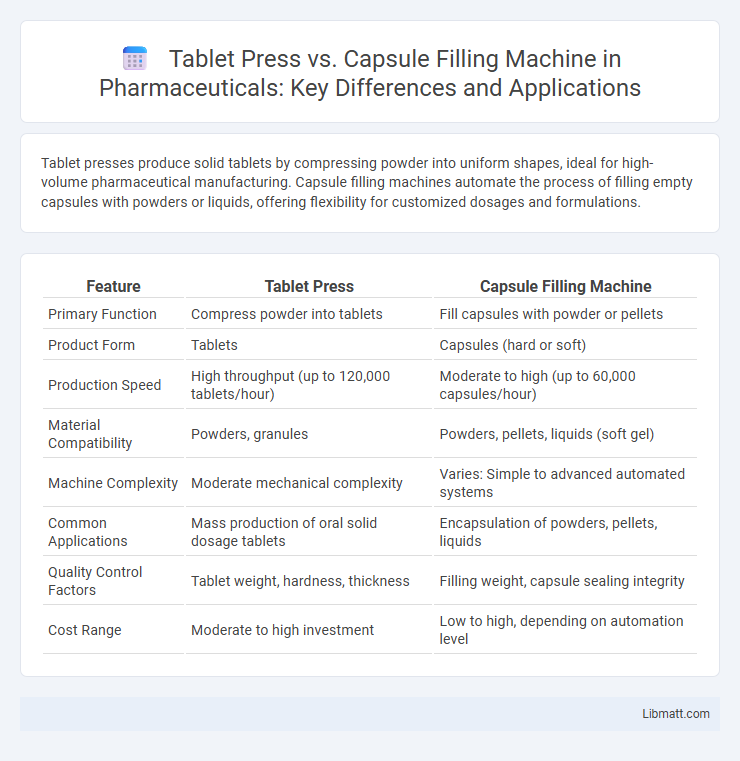

Tablet presses produce solid tablets by compressing powder into uniform shapes, ideal for high-volume pharmaceutical manufacturing. Capsule filling machines automate the process of filling empty capsules with powders or liquids, offering flexibility for customized dosages and formulations.

Table of Comparison

| Feature | Tablet Press | Capsule Filling Machine |

|---|---|---|

| Primary Function | Compress powder into tablets | Fill capsules with powder or pellets |

| Product Form | Tablets | Capsules (hard or soft) |

| Production Speed | High throughput (up to 120,000 tablets/hour) | Moderate to high (up to 60,000 capsules/hour) |

| Material Compatibility | Powders, granules | Powders, pellets, liquids (soft gel) |

| Machine Complexity | Moderate mechanical complexity | Varies: Simple to advanced automated systems |

| Common Applications | Mass production of oral solid dosage tablets | Encapsulation of powders, pellets, liquids |

| Quality Control Factors | Tablet weight, hardness, thickness | Filling weight, capsule sealing integrity |

| Cost Range | Moderate to high investment | Low to high, depending on automation level |

Introduction to Tablet Press and Capsule Filling Machines

Tablet presses are industrial machines designed to compress powdered materials into solid tablets with precise shape and dosage, essential in pharmaceutical manufacturing. Capsule filling machines automate the process of filling empty capsules with powders, granules, or liquids, ensuring accurate dosage and high production efficiency. Both machines play critical roles in drug formulation but differ significantly in their mechanics and output forms, catering to diverse medication delivery preferences.

Key Differences Between Tablet Press and Capsule Filling Machines

Tablet press machines compress powdered materials into solid tablets with consistent shape and dosage, ensuring precise medication delivery. Capsule filling machines, on the other hand, fill pre-made gelatin or vegetarian capsules with powders, granules, or liquids, allowing for versatile formulation options. Your choice depends on product type, production speed, and dosage form requirements, as tablet presses offer higher output while capsule fillers provide flexibility for various ingredients.

Working Principles of Tablet Press Machines

Tablet press machines operate by compressing powdered pharmaceutical ingredients into tablets using a combination of punches and dies that form specific shapes and sizes. The machine's rotary or single-station design ensures consistent pressure application, controlling tablet hardness, thickness, and weight for uniform dosage. Precision in filling compartments and punch movement is crucial to maintaining tablet quality and production efficiency compared to capsule filling machines, which rely on different mechanisms for encapsulating powders or granules.

How Capsule Filling Machines Operate

Capsule filling machines operate by precisely measuring powdered or granular substances and depositing them into two-piece capsules, typically made from gelatin or HPMC. The process involves separating the capsule body from the cap, filling the body with the product, and securely rejoining the two parts to ensure airtight sealing. These machines achieve high-speed, accurate dosing suitable for pharmaceutical and nutraceutical production, optimizing efficiency and minimizing product wastage.

Advantages of Using Tablet Press Machines

Tablet press machines offer high-speed production capabilities, making them ideal for large-scale pharmaceutical manufacturing. They provide precise dosage control and consistent tablet weight, ensuring rigorous quality standards. The versatility of tablet presses allows for a wide range of tablet shapes, sizes, and formulations, enhancing product customization.

Benefits of Capsule Filling Machines

Capsule filling machines offer precise dosage control and enhanced product consistency, which is essential for maintaining quality in pharmaceutical and nutraceutical production. These machines provide faster production speeds and reduced material waste compared to manual processes, improving overall operational efficiency. Your manufacturing process benefits from their ability to handle a wide variety of powder and pellet formulations, ensuring versatility and scalability in production.

Applications in Pharmaceutical Manufacturing

Tablet presses are widely used for mass-producing compressed tablets with precise dosages, ideal for solid oral dosage forms in pharmaceutical manufacturing. Capsule filling machines efficiently encapsulate powders, granules, or liquids, catering to formulations requiring fast dissolution and patient compliance. Your choice depends on the drug's physical properties, production volume, and desired release profile.

Cost Considerations and Efficiency

Tablet presses generally incur higher initial costs than capsule filling machines due to complex tooling and maintenance requirements. Capsule filling machines offer greater efficiency in processing soft and hard capsules with lower downtime and simplified changeovers. Cost considerations also include material usage, with tablets minimizing excipients, while capsules involve additional shell costs impacting overall production expenses.

Quality Control in Tablet and Capsule Production

Quality control in tablet press and capsule filling machine operations ensures consistent dosage accuracy, uniform weight, and proper hardness for tablets, while capsules require validation of fill volume, seal integrity, and shell integrity. Critical parameters such as granule flow properties, fill weight variation, and compression force for tablets, and powder flow consistency, capsule alignment, and fill uniformity for capsules are monitored using in-process control systems. Advanced inspection technologies like near-infrared spectroscopy and automated vision systems enhance defect detection, ensuring compliance with pharmacopeial standards and regulatory requirements in pharmaceutical manufacturing.

Choosing the Right Machine for Your Production Needs

Selecting the right equipment between a tablet press and a capsule filling machine depends on your product formulation, production volume, and desired dosage form. Tablet presses efficiently compress powders into solid tablets with high throughput, ideal for mass production and consistent tablet quality. Capsule filling machines offer flexibility for liquid, powder, or pellet filling, making them suitable for customizable doses and diverse pharmaceutical or nutraceutical applications.

Tablet press vs Capsule filling machine Infographic

libmatt.com

libmatt.com