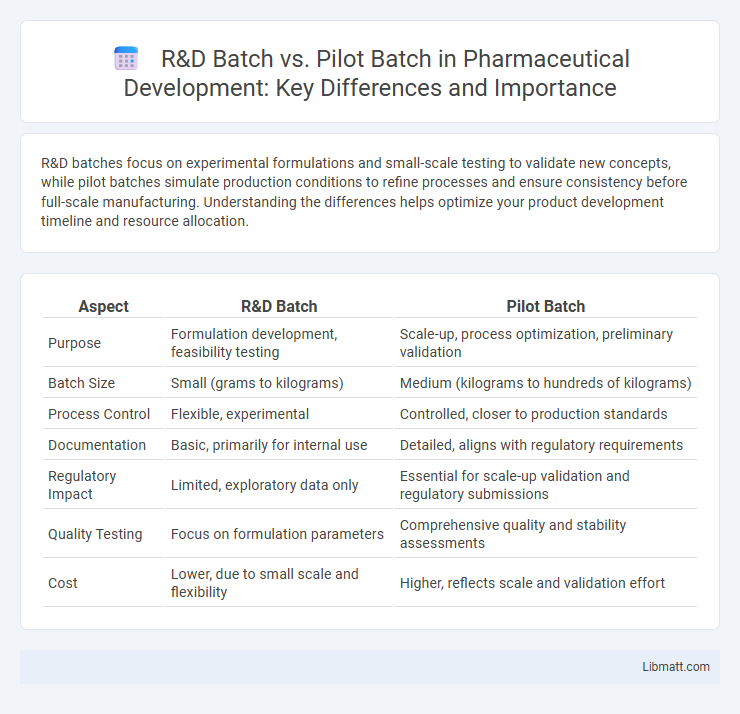

R&D batches focus on experimental formulations and small-scale testing to validate new concepts, while pilot batches simulate production conditions to refine processes and ensure consistency before full-scale manufacturing. Understanding the differences helps optimize your product development timeline and resource allocation.

Table of Comparison

| Aspect | R&D Batch | Pilot Batch |

|---|---|---|

| Purpose | Formulation development, feasibility testing | Scale-up, process optimization, preliminary validation |

| Batch Size | Small (grams to kilograms) | Medium (kilograms to hundreds of kilograms) |

| Process Control | Flexible, experimental | Controlled, closer to production standards |

| Documentation | Basic, primarily for internal use | Detailed, aligns with regulatory requirements |

| Regulatory Impact | Limited, exploratory data only | Essential for scale-up validation and regulatory submissions |

| Quality Testing | Focus on formulation parameters | Comprehensive quality and stability assessments |

| Cost | Lower, due to small scale and flexibility | Higher, reflects scale and validation effort |

Introduction to R&D Batch and Pilot Batch

R&D batch refers to an initial small-scale production run used to develop and optimize product formulations, processes, and specifications within a research and development environment. Pilot batch is a slightly larger-scale production that tests the feasibility of commercial manufacturing processes, often serving as a bridge between R&D and full-scale production. These batches play critical roles in product validation, scale-up assessments, and regulatory submissions in pharmaceutical, chemical, and manufacturing industries.

Definition of R&D Batch

An R&D batch refers to a small-scale production run designed primarily for experimental and developmental purposes, aiming to optimize formulation, process parameters, and product characteristics. It typically involves limited quantities and flexible protocols to facilitate testing, analysis, and refinement before scaling up. This batch plays a crucial role in identifying critical variables and ensuring reproducibility prior to the larger pilot batch stage.

Definition of Pilot Batch

A pilot batch refers to a small-scale production run designed to test manufacturing processes, evaluate product quality, and identify potential issues before full-scale commercial production. It serves as an intermediate step between the R&D batch, which focuses on initial formulation and feasibility, and the full production batch, ensuring scalability and process robustness. The pilot batch helps optimize process parameters, confirm equipment suitability, and validate product consistency under near-commercial conditions.

Key Objectives: R&D Batch vs Pilot Batch

R&D batches primarily focus on developing and optimizing the formulation, process parameters, and raw materials to establish proof of concept and initial feasibility. Pilot batches aim to scale up production, validate manufacturing processes, and generate data for commercial scale-up while ensuring product quality and consistency. Key objectives of R&D batches address innovation and experimentation, whereas pilot batches emphasize process robustness and regulatory compliance.

Process Workflow Differences

R&D batch workflow primarily emphasizes experimentation, parameter optimization, and small-scale testing to establish formulation feasibility and identify critical quality attributes. Pilot batch workflow scales up these processes with defined protocols to evaluate process reproducibility, equipment performance, and to generate material for stability studies and clinical trials. Differences include the level of process control, documentation rigor, and batch size, with pilot batches requiring more stringent adherence to production standards and regulatory compliance.

Scale and Production Volume Comparison

R&D batches are typically small-scale productions designed for initial testing and formulation development, often ranging from a few grams to several kilograms depending on the industry. Pilot batches serve as an intermediate scale, producing larger quantities--usually tens to hundreds of kilograms--to simulate full-scale manufacturing conditions and optimize processes before commercial production. Understanding the scale and production volume differences between R&D and pilot batches helps you accurately plan resource allocation and product scalability.

Regulatory and Compliance Considerations

R&D batches primarily focus on product development and characterization, with regulatory documentation often being preliminary and exploratory, whereas pilot batches are produced under stricter compliance standards to simulate commercial-scale manufacturing processes. Regulatory authorities require pilot batches to adhere to Good Manufacturing Practices (GMP) and be suitable for stability testing, ensuring data generated supports future regulatory submissions. You must ensure pilot batches meet defined quality criteria to validate manufacturing processes and facilitate smoother regulatory approval pathways.

Cost Implications and Resource Allocation

R&D batches typically involve smaller quantities and experimental protocols, resulting in lower initial costs but higher per-unit expenses due to bespoke processes. Pilot batches require more substantial resource allocation, including specialized equipment and workforce, to simulate full-scale production, increasing overall costs but providing critical data for cost optimization. Your strategic decision between these batches directly impacts budget management and resource deployment efficiency in product development.

Impact on Product Development Timeline

R&D batches primarily serve as initial experimental runs to validate formulations and process parameters, often requiring iterative adjustments that extend the product development timeline. Pilot batches, conducted after successful R&D trials, focus on scaling up production under conditions closer to commercial manufacturing, providing critical data that streamlines regulatory approval and manufacturing readiness. Efficient transition from R&D to pilot batches reduces unforeseen challenges, accelerating product launch schedules and minimizing time-to-market.

Choosing Between R&D Batch and Pilot Batch

Choosing between an R&D batch and a pilot batch depends on the stage of product development and specific objectives like formulation optimization or process validation. R&D batches are smaller, typically used for initial experimentation and identifying potential issues, while pilot batches are larger and simulate commercial production conditions to verify scalability and consistency. Prioritizing batch size and production variables ensures accurate data for quality control and regulatory compliance during product scale-up.

R&D batch vs pilot batch Infographic

libmatt.com

libmatt.com