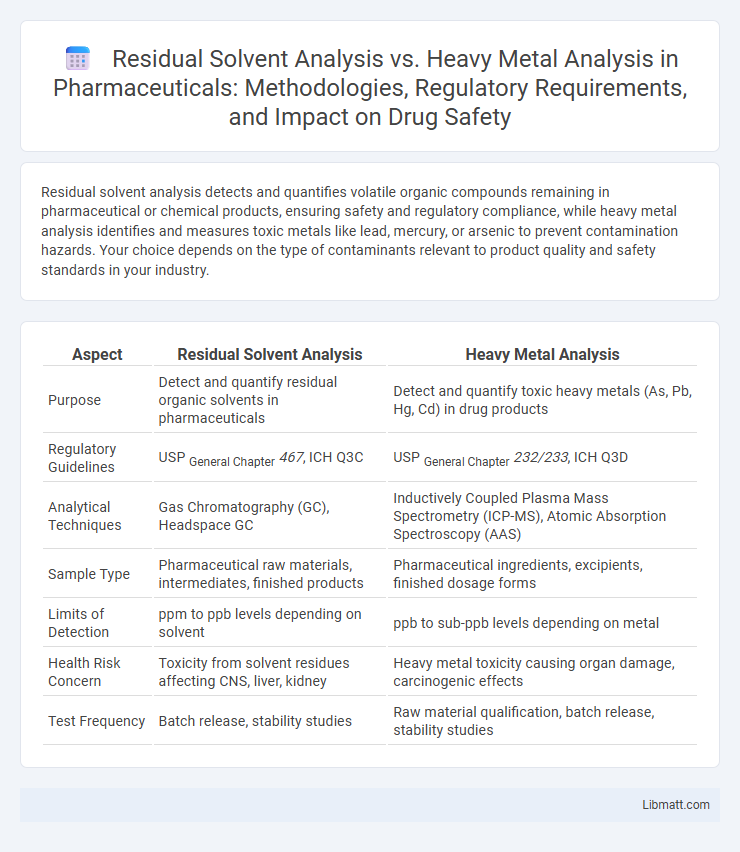

Residual solvent analysis detects and quantifies volatile organic compounds remaining in pharmaceutical or chemical products, ensuring safety and regulatory compliance, while heavy metal analysis identifies and measures toxic metals like lead, mercury, or arsenic to prevent contamination hazards. Your choice depends on the type of contaminants relevant to product quality and safety standards in your industry.

Table of Comparison

| Aspect | Residual Solvent Analysis | Heavy Metal Analysis |

|---|---|---|

| Purpose | Detect and quantify residual organic solvents in pharmaceuticals | Detect and quantify toxic heavy metals (As, Pb, Hg, Cd) in drug products |

| Regulatory Guidelines | USP General Chapter 467, ICH Q3C | USP General Chapter 232/233, ICH Q3D |

| Analytical Techniques | Gas Chromatography (GC), Headspace GC | Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectroscopy (AAS) |

| Sample Type | Pharmaceutical raw materials, intermediates, finished products | Pharmaceutical ingredients, excipients, finished dosage forms |

| Limits of Detection | ppm to ppb levels depending on solvent | ppb to sub-ppb levels depending on metal |

| Health Risk Concern | Toxicity from solvent residues affecting CNS, liver, kidney | Heavy metal toxicity causing organ damage, carcinogenic effects |

| Test Frequency | Batch release, stability studies | Raw material qualification, batch release, stability studies |

Introduction to Residual Solvent and Heavy Metal Analysis

Residual solvent analysis focuses on detecting and quantifying volatile organic compounds used during pharmaceutical manufacturing that may remain in drug products, ensuring compliance with regulatory limits to protect patient safety. Heavy metal analysis identifies and measures toxic metals like lead, cadmium, arsenic, and mercury in raw materials and finished products, preventing contamination that could cause severe health risks. Your quality control processes rely on both analyses to guarantee product purity and regulatory adherence.

Importance in Pharmaceutical and Food Industries

Residual solvent analysis and heavy metal analysis are critical for ensuring safety and regulatory compliance in pharmaceutical and food industries. Residual solvent analysis detects volatile organic compounds that can pose toxicity risks, while heavy metal analysis identifies toxic elements like lead, mercury, and cadmium that can accumulate and cause severe health effects. Both analyses help maintain product quality, protect consumer health, and adhere to international standards such as USP, ICH, and FDA guidelines.

Definition of Residual Solvent Analysis

Residual solvent analysis involves identifying and quantifying trace amounts of volatile organic compounds left in pharmaceutical products after manufacturing. This process ensures compliance with regulatory limits set by agencies like the FDA and ICH to prevent potential toxicity in patients. Your quality control protocols depend heavily on accurate residual solvent analysis to maintain product safety and efficacy.

Overview of Heavy Metal Analysis

Heavy metal analysis involves detecting and quantifying toxic metals such as lead, mercury, cadmium, and arsenic in various samples to ensure safety and regulatory compliance. Techniques like atomic absorption spectroscopy (AAS), inductively coupled plasma mass spectrometry (ICP-MS), and X-ray fluorescence (XRF) provide sensitive and accurate measurements critical for environmental monitoring, pharmaceuticals, and food safety. You benefit from heavy metal analysis by identifying contamination risks early, protecting health, and meeting industry standards.

Regulatory Guidelines and Compliance Standards

Residual solvent analysis adheres to ICH Q3C guidelines, which classify solvents based on toxicity and set permissible daily exposure limits to ensure pharmaceutical safety. Heavy metal analysis follows pharmacopoeial standards such as USP <232> and ICH Q3D, specifying permissible limits for elemental impurities to prevent toxic metal contamination. Compliance with these regulatory frameworks is critical for drug approval and market access, ensuring both solvent and heavy metal residues are within safe thresholds.

Analytical Methods for Residual Solvent Detection

Gas chromatography (GC) is the primary analytical method for residual solvent detection, offering high sensitivity and specificity for volatile organic compounds in pharmaceutical products. Headspace GC enhances sample introduction by volatilizing solvents above the sample matrix, improving detection limits and accuracy. Techniques such as flame ionization detection (FID) and mass spectrometry (MS) coupled with GC provide robust quantification and identification of residual solvents in compliance with ICH Q3C guidelines.

Techniques for Heavy Metal Quantification

Techniques for heavy metal quantification include atomic absorption spectroscopy (AAS), inductively coupled plasma mass spectrometry (ICP-MS), and inductively coupled plasma optical emission spectrometry (ICP-OES), each providing precise measurement of trace metals in pharmaceutical samples. Unlike residual solvent analysis, which relies on gas chromatography (GC) and gas chromatography-mass spectrometry (GC-MS) to detect volatile organic compounds, heavy metal analysis focuses on elemental detection through these spectroscopic methods. Your choice of technique depends on the required sensitivity, sample matrix, and regulatory standards for pharmaceutical quality control.

Sample Preparation and Validation Processes

Residual solvent analysis requires meticulous sample preparation involving solvent extraction or headspace sampling to accurately quantify volatile organic compounds, with validation processes emphasizing limits of detection (LOD), limits of quantification (LOQ), and specificity according to USP <467> guidelines. Heavy metal analysis involves acid digestion or microwave-assisted extraction to release metals into solution, with validation focused on ensuring accuracy, precision, recovery rates, and method linearity per USP <233> and USP <232>. Both methods demand rigorous calibration, use of certified reference materials, and adherence to regulatory standards to ensure reliable contaminant quantification in pharmaceutical products.

Common Challenges and Interferences

Residual solvent analysis often faces challenges due to co-eluting volatile compounds and matrix interferences that can obscure chromatographic signals, while heavy metal analysis struggles with spectral interferences from overlapping elemental emissions or absorptions in techniques like ICP-MS and AAS. Both analyses require rigorous sample preparation to minimize contamination and matrix effects which can lead to inaccurate quantification. Accurate detection demands optimized method validation and proper calibration to distinguish target analytes from background noise and potential contaminants.

Conclusion: Comparing Risks and Best Practices

Residual solvent analysis identifies volatile organic compounds that may pose inhalation or toxicity risks, while heavy metal analysis detects toxic elements like lead, arsenic, and mercury known for bioaccumulation and chronic health effects. Prioritizing safety demands stringent regulatory limits such as USP <467> for solvents and USP <232>/<233> for heavy metals, ensuring both test types complement comprehensive quality control. Employing robust analytical techniques like GC-MS for solvents and ICP-MS for metals optimizes detection sensitivity, supporting best practices in pharmaceutical and dietary supplement manufacturing.

Residual solvent analysis vs heavy metal analysis Infographic

libmatt.com

libmatt.com