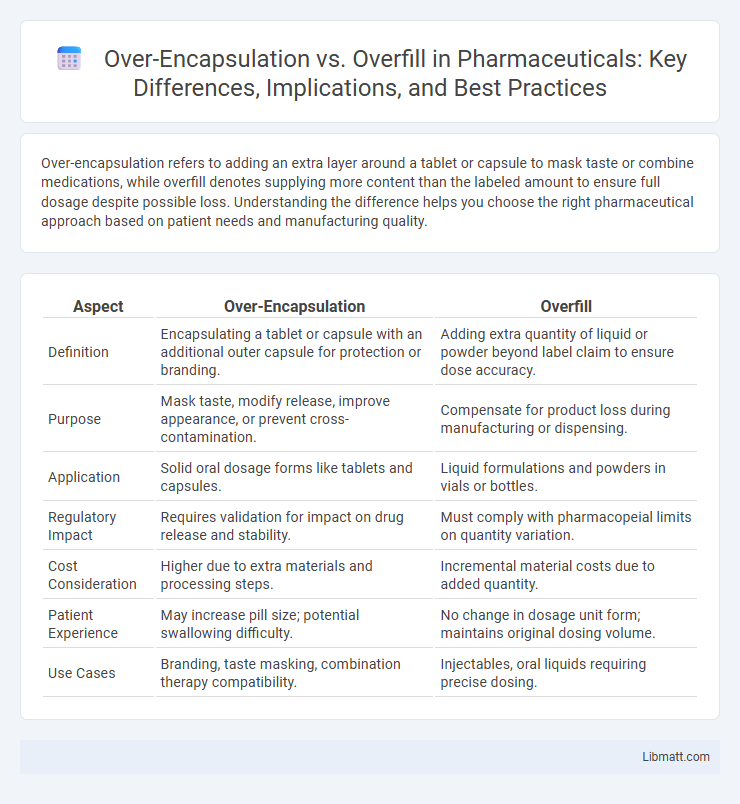

Over-encapsulation refers to adding an extra layer around a tablet or capsule to mask taste or combine medications, while overfill denotes supplying more content than the labeled amount to ensure full dosage despite possible loss. Understanding the difference helps you choose the right pharmaceutical approach based on patient needs and manufacturing quality.

Table of Comparison

| Aspect | Over-Encapsulation | Overfill |

|---|---|---|

| Definition | Encapsulating a tablet or capsule with an additional outer capsule for protection or branding. | Adding extra quantity of liquid or powder beyond label claim to ensure dose accuracy. |

| Purpose | Mask taste, modify release, improve appearance, or prevent cross-contamination. | Compensate for product loss during manufacturing or dispensing. |

| Application | Solid oral dosage forms like tablets and capsules. | Liquid formulations and powders in vials or bottles. |

| Regulatory Impact | Requires validation for impact on drug release and stability. | Must comply with pharmacopeial limits on quantity variation. |

| Cost Consideration | Higher due to extra materials and processing steps. | Incremental material costs due to added quantity. |

| Patient Experience | May increase pill size; potential swallowing difficulty. | No change in dosage unit form; maintains original dosing volume. |

| Use Cases | Branding, taste masking, combination therapy compatibility. | Injectables, oral liquids requiring precise dosing. |

Introduction to Over-Encapsulation and Overfill

Over-encapsulation occurs when a coating or encapsulating material is applied in excess, leading to reduced device performance and increased manufacturing costs. Overfill refers to the surplus amount of encapsulant dispensed beyond its intended volume, causing material waste, potential component damage, and compromised product reliability. Both phenomena highlight the critical need for precise control in encapsulation processes to ensure optimal protection and functionality of electronic components.

Defining Over-Encapsulation in Pharmaceuticals

Over-encapsulation in pharmaceuticals involves enclosing an existing tablet or capsule within a larger, uniform capsule shell to mask taste, improve swallowability, or facilitate clinical trials. This technique ensures the drug's original form remains intact while allowing for modifications in appearance, dosage, or compliance without altering the active ingredient. Overfill, by contrast, refers to adding extra quantity of drug substance to account for manufacturing loss or ensure potency, which is fundamentally different from over-encapsulation's purpose of physical modification and administration control.

Understanding Overfill in Drug Manufacturing

Overfill in drug manufacturing refers to the practice of adding extra volume or mass beyond the labeled amount to ensure dosage accuracy and compensate for potential losses during processing and handling. Understanding overfill is crucial as it directly impacts cost-efficiency, regulatory compliance, and product safety by preventing underdosing or wastage. You must balance overfill carefully to avoid excessive medication use or packaging inconsistencies while maintaining therapeutic effectiveness.

Key Differences Between Over-Encapsulation and Overfill

Over-encapsulation involves adding an extra capsule layer around a primary capsule to mask taste or protect the contents, whereas overfill refers to placing more product inside a capsule than its labeled dosage. Overfill can affect dosage accuracy and regulatory compliance, while over-encapsulation primarily impacts manufacturing complexity and patient swallowing ease. Understanding these key differences helps optimize product formulation and ensures Your medication meets quality and safety standards.

Regulatory Guidelines for Over-Encapsulation and Overfill

Regulatory guidelines for over-encapsulation require precise adherence to capsule size and material standards to ensure drug stability and patient safety, with agencies like the FDA mandating thorough documentation of the encapsulation process. Overfill regulations focus on permissible tolerance levels, ensuring that drug quantities exceed the labeled dose only within strict limits to prevent dosing errors and maintain efficacy. Both practices demand rigorous quality control measures compliant with pharmacopeial standards such as USP and EMA directives to guarantee consistent product performance.

Quality Control Considerations

Quality control considerations for over-encapsulation versus overfill center on ensuring dosage accuracy and product uniformity. Over-encapsulation requires rigorous inspection to verify capsule integrity and active ingredient consistency, while overfill demands precise volume measurements to avoid dosage variances and potential regulatory non-compliance. Both processes necessitate stringent monitoring protocols and analytical testing to maintain pharmaceutical quality standards and patient safety.

Impact on Clinical Trial Blinding and Compliance

Over-encapsulation alters the physical appearance of medications, enhancing clinical trial blinding by preventing identification through taste, color, or shape, which improves trial integrity and reduces bias. Overfill ensures accurate dosing by compensating for potential losses during dosing, supporting compliance with regulatory standards for drug delivery precision. Both techniques contribute to reliable clinical outcomes by maintaining treatment consistency and patient adherence.

Cost Implications of Over-Encapsulation vs. Overfill

Over-encapsulation increases packaging costs due to additional materials and labor, whereas overfill raises product costs by using excess raw materials. Your packaging budget may surge with over-encapsulation, but overfill directly impacts profit margins through wasted product quantity. Optimizing both methods reduces unnecessary expenses and improves cost-efficiency in pharmaceutical packaging.

Common Applications and Use Cases

Over-encapsulation is commonly used in pharmaceutical and electronic industries to improve product protection and enhance compatibility by adding an extra layer around components or medications. Overfill is predominantly applied in packaging and manufacturing sectors to ensure accurate dosing or volume measurement, compensating for potential evaporation, spillage, or measurement variability. Both techniques are essential for maintaining product integrity and regulatory compliance in fields such as drug delivery systems, food and beverage packaging, and chemical processing.

Best Practices for Selecting Between Over-Encapsulation and Overfill

Selecting between over-encapsulation and overfill depends on factors like product stability, dosage precision, and container compatibility. Over-encapsulation is ideal for protecting tablets from environmental factors and masking taste without altering dosage, while overfill is preferred for liquids where maintaining a consistent volume compensates for potential evaporation or handling losses. Evaluating the specific formulation requirements, regulatory guidelines, and cost implications ensures optimal packaging integrity and patient compliance.

Over-encapsulation vs overfill Infographic

libmatt.com

libmatt.com