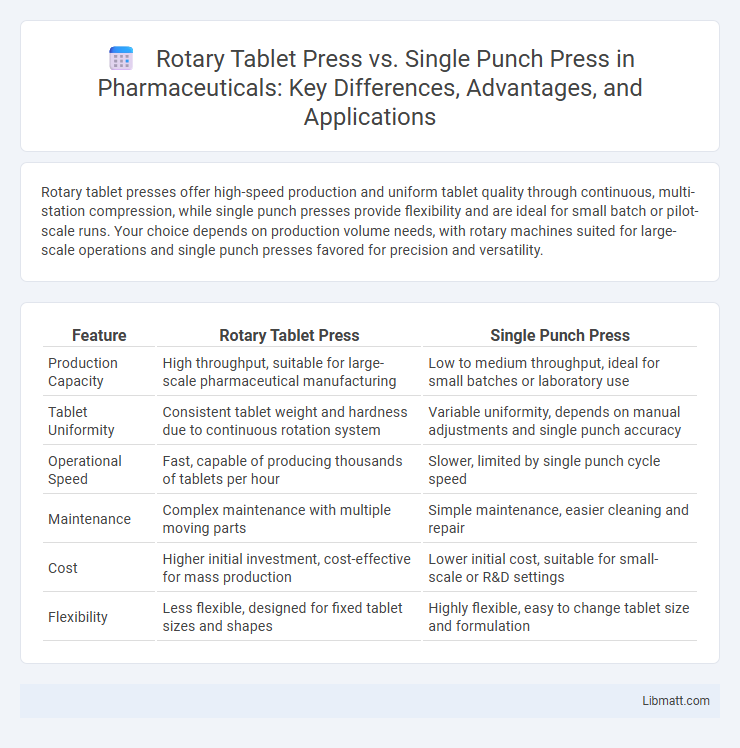

Rotary tablet presses offer high-speed production and uniform tablet quality through continuous, multi-station compression, while single punch presses provide flexibility and are ideal for small batch or pilot-scale runs. Your choice depends on production volume needs, with rotary machines suited for large-scale operations and single punch presses favored for precision and versatility.

Table of Comparison

| Feature | Rotary Tablet Press | Single Punch Press |

|---|---|---|

| Production Capacity | High throughput, suitable for large-scale pharmaceutical manufacturing | Low to medium throughput, ideal for small batches or laboratory use |

| Tablet Uniformity | Consistent tablet weight and hardness due to continuous rotation system | Variable uniformity, depends on manual adjustments and single punch accuracy |

| Operational Speed | Fast, capable of producing thousands of tablets per hour | Slower, limited by single punch cycle speed |

| Maintenance | Complex maintenance with multiple moving parts | Simple maintenance, easier cleaning and repair |

| Cost | Higher initial investment, cost-effective for mass production | Lower initial cost, suitable for small-scale or R&D settings |

| Flexibility | Less flexible, designed for fixed tablet sizes and shapes | Highly flexible, easy to change tablet size and formulation |

Introduction to Tablet Press Machines

Rotary tablet press machines offer high-speed production and consistent tablet quality by using multiple punches rotating around a central turret, making them ideal for large-scale pharmaceutical manufacturing. Single punch presses operate with one punch at a time, providing flexibility and precision for small batch production or research and development purposes. Your choice between these machines depends on the production volume, tablet complexity, and overall efficiency required for your tablet manufacturing process.

Overview of Rotary Tablet Press

Rotary tablet presses are high-capacity machines designed to compress powder into tablets through multiple stations rotating around a central turret, enabling fast and efficient production suitable for large pharmaceutical batches. Unlike single punch presses that compress one tablet per cycle, rotary presses consist of multiple punches and dies, dramatically increasing output while maintaining consistent tablet quality. Your choice of a rotary tablet press enhances productivity and precision, making it ideal for scaling up tablet manufacturing processes.

Overview of Single Punch Press

A Single Punch Press operates by compressing powdered material between a stationary die and a single punch, producing tablets one at a time. It is ideal for small-scale production or R&D due to its simplicity, lower cost, and ease of maintenance compared to Rotary Tablet Presses. Typical applications include pharmaceutical, nutraceutical, and specialty tablet manufacturing where batch sizes are limited.

Key Differences Between Rotary and Single Punch Press

Rotary tablet presses offer high-speed, continuous production by using multiple punches rotating around a turret, whereas single punch presses utilize a single punch for batch processing, resulting in slower output. Rotary presses are ideal for large-scale pharmaceutical manufacturing due to their efficiency and consistency, while single punch presses provide greater flexibility for small-scale or custom formulations. The complexity and cost of rotary presses are higher compared to the simpler, more affordable single punch presses, which makes each suitable for different production needs and volumes.

Production Capacity Comparison

Rotary tablet presses deliver significantly higher production capacity, capable of compressing thousands of tablets per minute due to multiple tooling stations rotating simultaneously. Single punch presses operate one tablet at a time, resulting in much lower output, often suitable for small batches or pilot production. The continuous, high-speed operation of rotary presses makes them ideal for large-scale pharmaceutical manufacturing, where efficiency and volume are critical.

Tablet Quality and Consistency

Rotary tablet presses deliver superior tablet quality and consistency through their multi-station design, enabling continuous high-speed compression with uniform pressure distribution. Single punch presses, while cost-effective and suitable for small batches, often exhibit variability in tablet weight and hardness due to their manual or semi-automatic operation. Your production benefits from rotary presses when consistent tablet integrity and precision are critical for pharmaceutical or nutraceutical applications.

Space and Energy Requirements

Rotary tablet presses require significantly more floor space compared to single punch presses due to their complex multi-station tooling systems designed for high-volume production. Energy consumption in rotary presses is generally higher, driven by motors powering multiple punches simultaneously at high speeds. Single punch presses are more compact and consume less power, making them ideal for low-volume or laboratory-scale tablet production where space and energy efficiency are critical.

Maintenance and Operation Complexity

Rotary tablet presses require more complex maintenance due to their multiple tooling stations and synchronization mechanisms, necessitating regular inspection and precise calibration to ensure consistent tablet quality. Single punch presses feature simpler operation and maintenance processes, with fewer moving parts and easier access to tooling, reducing downtime and operator training requirements. Efficient maintenance protocols for rotary presses are crucial to avoid production delays, while single punch presses offer advantages in low-volume, quick-change applications.

Cost Analysis and Return on Investment

Rotary tablet presses typically require higher initial capital investment compared to single punch presses, but their capacity for high-speed production offers superior economies of scale and faster ROI in large-scale manufacturing. Single punch presses have lower upfront costs and simpler maintenance, making them cost-effective for small batch production or R&D settings, though their slower output limits profitability in mass production. Assessing total cost of ownership includes factors like tooling, energy consumption, and downtime, where rotary presses generally deliver greater long-term savings through efficiency and reduced labor costs.

Choosing the Right Tablet Press for Your Needs

Rotary tablet presses offer high-speed production and uniform tablet quality, making them ideal for large-scale pharmaceutical manufacturing, while single punch presses provide flexibility and cost-effectiveness suited for small batches or research applications. Your choice depends on factors such as production volume, tablet complexity, and budget constraints. Evaluating these criteria ensures you select the right tablet press to optimize efficiency and meet your specific manufacturing requirements.

Rotary Tablet Press vs Single Punch Press Infographic

libmatt.com

libmatt.com