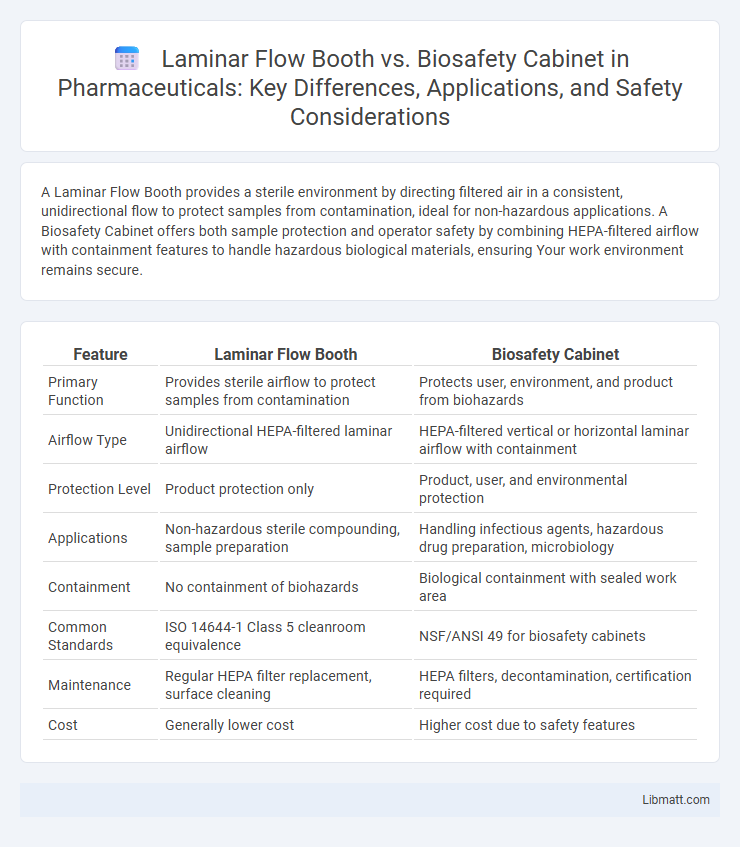

A Laminar Flow Booth provides a sterile environment by directing filtered air in a consistent, unidirectional flow to protect samples from contamination, ideal for non-hazardous applications. A Biosafety Cabinet offers both sample protection and operator safety by combining HEPA-filtered airflow with containment features to handle hazardous biological materials, ensuring Your work environment remains secure.

Table of Comparison

| Feature | Laminar Flow Booth | Biosafety Cabinet |

|---|---|---|

| Primary Function | Provides sterile airflow to protect samples from contamination | Protects user, environment, and product from biohazards |

| Airflow Type | Unidirectional HEPA-filtered laminar airflow | HEPA-filtered vertical or horizontal laminar airflow with containment |

| Protection Level | Product protection only | Product, user, and environmental protection |

| Applications | Non-hazardous sterile compounding, sample preparation | Handling infectious agents, hazardous drug preparation, microbiology |

| Containment | No containment of biohazards | Biological containment with sealed work area |

| Common Standards | ISO 14644-1 Class 5 cleanroom equivalence | NSF/ANSI 49 for biosafety cabinets |

| Maintenance | Regular HEPA filter replacement, surface cleaning | HEPA filters, decontamination, certification required |

| Cost | Generally lower cost | Higher cost due to safety features |

Introduction to Controlled Environment Solutions

Laminar flow booths provide a sterile environment by directing HEPA-filtered air in a uniform flow to protect samples from contamination, commonly used in electronics and pharmaceutical labs. Biosafety cabinets offer an enclosed, ventilated workspace with HEPA filtration, designed to safeguard both the user and the environment from biohazards during microbiological work. Both controlled environment solutions utilize high-efficiency particulate air filtration but differ in airflow design and protection levels tailored to specific laboratory applications.

What is a Laminar Flow Booth?

A Laminar Flow Booth is a controlled environment designed to provide a sterile workspace by directing filtered air in a unidirectional flow across the work surface. It uses High-Efficiency Particulate Air (HEPA) filters to remove contaminants, protecting samples from airborne particles and microorganisms. Unlike Biosafety Cabinets, Laminar Flow Booths primarily protect the product but do not offer personnel or environmental protection from hazardous materials.

Understanding Biosafety Cabinets

Biosafety cabinets (BSCs) provide critical protection by filtering air to prevent exposure to hazardous biological agents, ensuring both product and user safety through HEPA filtration and controlled airflow. Unlike laminar flow booths, which primarily protect the sample from contamination by directing filtered air over the work surface, BSCs are specifically designed to safeguard the operator, the environment, and the material being handled. Understanding these differences helps you choose the right containment device based on your laboratory's biosafety requirements and the nature of your work.

Key Differences Between Laminar Flow Booths and Biosafety Cabinets

Laminar flow booths provide a sterile work environment by directing unidirectional airflow to protect samples from contamination, but they do not protect the user or environment from hazardous materials. Biosafety cabinets (BSCs) incorporate HEPA filters and maintain negative pressure to contain biohazardous aerosols, ensuring protection for the user, product, and environment. The key difference lies in the containment capability: laminar flow booths focus solely on product protection, while biosafety cabinets offer comprehensive biosafety with containment features for infectious agents.

Airflow Patterns and Contamination Control

Laminar Flow Booths utilize unidirectional, horizontal or vertical airflow to create a sterile environment by continuously sweeping contaminants away from the work surface, effectively minimizing particulate contamination. Biosafety Cabinets combine controlled airflow with HEPA filtration and inward airflow to protect both the product and user by containing biohazardous materials and preventing cross-contamination. Understanding these distinct airflow patterns is crucial for selecting the right equipment to maintain optimal contamination control in your laboratory or clinical workspace.

Protection Levels: Product, Operator, and Environment

Laminar flow booths provide unidirectional airflow to protect the product from contamination but do not safeguard the operator or the environment. Biosafety cabinets offer comprehensive protection by filtering air to shield the product, protect the operator from hazardous agents, and prevent environmental contamination through HEPA or ULPA filters. Selecting between a laminar flow booth and a biosafety cabinet depends on the required protection levels for the product, operator safety, and environmental containment.

Applications in Laboratories and Industry

Laminar flow booths provide unidirectional airflow to create a contamination-free environment ideal for electronics assembly, pharmaceutical compounding, and tissue culture applications. Biosafety cabinets offer enhanced protection by filtering air through HEPA filters and contain biological hazards, making them essential in microbiology labs, clinical diagnostics, and research involving pathogenic agents. The choice between laminar flow booths and biosafety cabinets depends on the level of airborne contamination control and biosafety required for specific laboratory and industrial processes.

Regulatory Compliance and Safety Standards

Laminar flow booths provide a sterile environment by directing unidirectional airflow to protect your samples, but they do not offer personnel or environmental protection, thus not meeting biosafety cabinet (BSC) regulatory standards. Biosafety cabinets comply with strict OSHA, NSF/ANSI 49, and CDC guidelines, ensuring containment of biohazards through HEPA-filtered airflow and proper exhaust systems to safeguard both user and environment. Your choice should align with regulatory compliance needs: laminar flow booths suit clean sample handling, while BSCs are mandatory for work involving infectious agents or hazardous materials.

Maintenance and Operational Considerations

Laminar Flow Booths require regular filter inspections and timely replacement of HEPA filters to maintain sterile airflow, with minimal calibration needs due to their straightforward design. Biosafety Cabinets demand more rigorous maintenance, including certification for airflow integrity, decontamination protocols, and monitoring of airflow alarms to ensure operator safety and containment. Your operational efficiency depends on understanding these maintenance requirements, as Biosafety Cabinets often involve higher costs and stricter regulatory compliance compared to Laminar Flow Booths.

Choosing the Right Solution for Your Needs

Selecting between a Laminar Flow Booth and a Biosafety Cabinet depends on the specific laboratory requirements regarding contamination control and personnel safety. Laminar Flow Booths provide unidirectional airflow to protect samples from particulate contamination, ideal for sterile work without hazardous materials. Biosafety Cabinets combine airflow filtration and containment features to shield both the user and environment, essential for handling infectious agents and biohazardous substances.

Laminar Flow Booth vs Biosafety Cabinet Infographic

libmatt.com

libmatt.com