CIP (Carriage and Insurance Paid to) requires the seller to cover transportation costs and insurance until the goods reach the named destination, providing comprehensive risk coverage. SIP (Session Initiation Protocol) is a communication protocol used for initiating, maintaining, and terminating real-time sessions, such as voice or video calls, in IP networks.

Table of Comparison

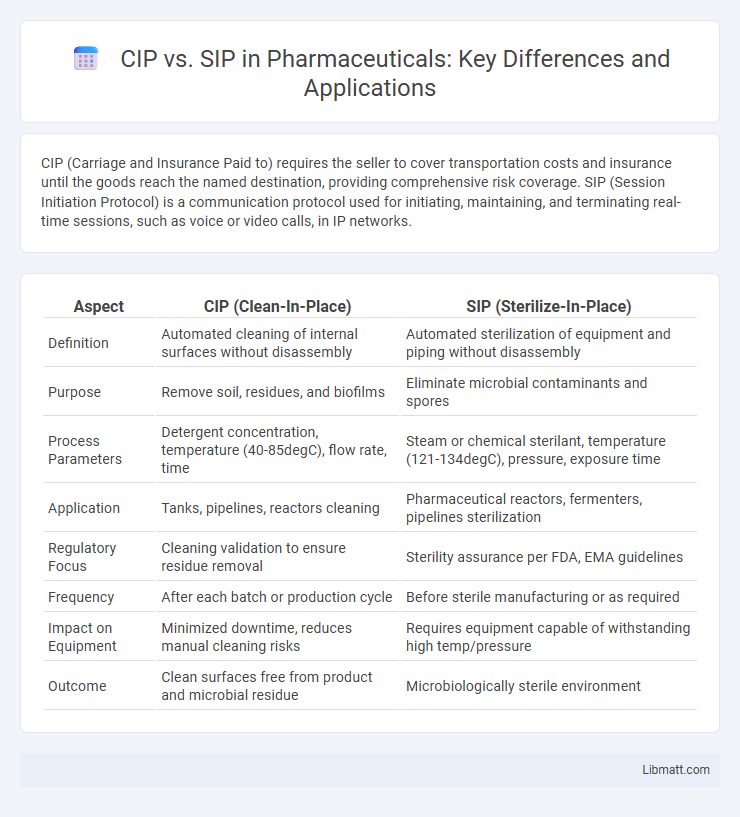

| Aspect | CIP (Clean-In-Place) | SIP (Sterilize-In-Place) |

|---|---|---|

| Definition | Automated cleaning of internal surfaces without disassembly | Automated sterilization of equipment and piping without disassembly |

| Purpose | Remove soil, residues, and biofilms | Eliminate microbial contaminants and spores |

| Process Parameters | Detergent concentration, temperature (40-85degC), flow rate, time | Steam or chemical sterilant, temperature (121-134degC), pressure, exposure time |

| Application | Tanks, pipelines, reactors cleaning | Pharmaceutical reactors, fermenters, pipelines sterilization |

| Regulatory Focus | Cleaning validation to ensure residue removal | Sterility assurance per FDA, EMA guidelines |

| Frequency | After each batch or production cycle | Before sterile manufacturing or as required |

| Impact on Equipment | Minimized downtime, reduces manual cleaning risks | Requires equipment capable of withstanding high temp/pressure |

| Outcome | Clean surfaces free from product and microbial residue | Microbiologically sterile environment |

Introduction to CIP and SIP

CIP (Cleaning in Place) refers to an automated cleaning process used in industries like food and beverage, pharmaceuticals, and chemicals to clean interior surfaces of pipes, vessels, and equipment without disassembly. SIP (Sterilization in Place) involves the sterilization of these same internal surfaces through methods such as steam or chemical sterilants, ensuring microbial decontamination without equipment removal. Both CIP and SIP systems are critical for maintaining hygiene standards, reducing contamination risks, and enhancing operational efficiency in manufacturing processes.

Defining CIP (Clean-in-Place)

CIP (Clean-in-Place) is an automated cleaning method used in industries such as food, beverage, and pharmaceuticals to clean equipment interiors without disassembly. This process involves circulating cleaning and sanitizing solutions through pipelines, tanks, and other components, ensuring thorough sanitation while minimizing downtime. Your facility benefits from CIP by maintaining hygiene standards efficiently and reducing labor costs compared to manual cleaning methods.

Defining SIP (Sterilize-in-Place)

Sterilize-in-Place (SIP) is a critical process designed to sterilize equipment and piping systems within pharmaceutical and food industries without disassembly, using high-temperature steam or chemical agents. SIP ensures the elimination of microbial contaminants, maintaining aseptic conditions and compliance with stringent regulatory standards such as FDA and EMA guidelines. Your facility benefits from SIP through reduced downtime, enhanced product safety, and minimized risk of cross-contamination compared to traditional sterilization methods.

Key Differences Between CIP and SIP

CIP (Cleaning in Place) and SIP (Sterilization in Place) are essential processes in pharmaceutical and food industries, designed to maintain hygiene without disassembling equipment. CIP focuses on removing soil, debris, and microbial contaminants using detergents and water, while SIP uses steam or chemical agents to achieve complete sterility by killing all microorganisms. Understanding these key differences helps you select the appropriate method to ensure product safety and process efficiency.

Critical Applications of CIP

Critical applications of CIP (Common Industrial Protocol) include real-time control and automation in manufacturing, energy, and transportation sectors where high reliability and deterministic communication are essential. CIP supports seamless integration across diverse devices and networks, ensuring efficient data exchange for process monitoring, safety systems, and predictive maintenance. Its robust architecture enhances operational efficiency and reduces downtime in critical industrial environments.

Essential Uses of SIP

Session Initiation Protocol (SIP) is essential for establishing, modifying, and terminating real-time multimedia communication sessions, including voice and video calls over IP networks. SIP enables seamless VoIP telephony, video conferencing, instant messaging, and presence information, making it integral to modern unified communication systems. Its interoperability and scalability support diverse applications such as IP telephony devices, mobile VoIP apps, and enterprise communication platforms.

Equipment and System Requirements

CIP (Clean-in-Place) systems require specialized, automated cleaning equipment integrated with tanks, pipelines, and valves designed to withstand repeated exposure to cleaning chemicals and high temperatures without disassembly. SIP (Sterilize-in-Place) demands autoclave-grade steam generators or sterilization units capable of achieving and maintaining precise high-temperature sterilization cycles within sealed systems, often including sensors and controls for pressure and temperature monitoring. Both CIP and SIP systems necessitate corrosion-resistant materials and robust control systems to ensure effective, contamination-free processing in pharmaceutical and food industries.

Advantages and Disadvantages of CIP

CIP (Clean-in-Place) systems offer significant advantages such as improved hygiene through automated cleaning processes, reduced labor costs, and minimized downtime in industries like food, beverage, and pharmaceuticals. However, disadvantages include high initial setup costs, complexity in system design requiring precise validation, and potential challenges in cleaning efficacy for equipment with complex geometries. Selecting CIP over SIP (Steam-in-Place) depends on specific process requirements, where CIP excels in chemical cleaning efficiency but may be less effective compared to SIP's sterilization capabilities.

Advantages and Disadvantages of SIP

Session Initiation Protocol (SIP) offers advantages such as compatibility with multiple devices, easier scalability, and support for video and instant messaging alongside voice calls. However, SIP may experience security vulnerabilities requiring robust encryption and can suffer from NAT traversal issues impacting call quality. Your choice should consider the flexibility and integration SIP provides against potential complexity in configuration and maintenance.

Choosing Between CIP and SIP: Best Practices

When choosing between Clean-in-Place (CIP) and Steam-in-Place (SIP) systems, consider the nature of the equipment and the required sanitation standards. CIP is best suited for routine cleaning in food, beverage, and pharmaceutical industries, using chemical detergents and water circulation without disassembly. SIP is ideal for sterilization needs, utilizing high-temperature steam to ensure microbial elimination, making it essential for aseptic processing environments.

CIP vs SIP Infographic

libmatt.com

libmatt.com