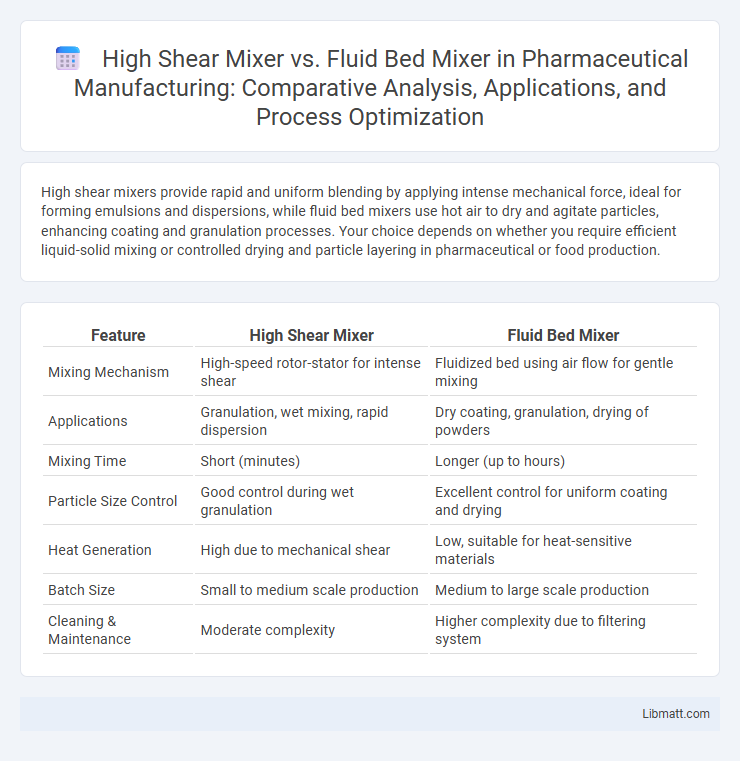

High shear mixers provide rapid and uniform blending by applying intense mechanical force, ideal for forming emulsions and dispersions, while fluid bed mixers use hot air to dry and agitate particles, enhancing coating and granulation processes. Your choice depends on whether you require efficient liquid-solid mixing or controlled drying and particle layering in pharmaceutical or food production.

Table of Comparison

| Feature | High Shear Mixer | Fluid Bed Mixer |

|---|---|---|

| Mixing Mechanism | High-speed rotor-stator for intense shear | Fluidized bed using air flow for gentle mixing |

| Applications | Granulation, wet mixing, rapid dispersion | Dry coating, granulation, drying of powders |

| Mixing Time | Short (minutes) | Longer (up to hours) |

| Particle Size Control | Good control during wet granulation | Excellent control for uniform coating and drying |

| Heat Generation | High due to mechanical shear | Low, suitable for heat-sensitive materials |

| Batch Size | Small to medium scale production | Medium to large scale production |

| Cleaning & Maintenance | Moderate complexity | Higher complexity due to filtering system |

Introduction to Mixing Technologies

High shear mixers utilize intense mechanical agitation to rapidly blend ingredients, ideal for emulsions, suspensions, and powder-liquid mixing in pharmaceutical and food industries. Fluid bed mixers employ a fluidization process, suspending particles in a hot air stream for efficient drying, coating, and granulation, commonly used in solid dosage and chemical processing. Both technologies enhance product homogeneity and processing speed but differ in energy input, applicable material types, and final product characteristics.

What is a High Shear Mixer?

A High Shear Mixer is an industrial device designed for rapid mixing, emulsifying, and homogenizing of materials using intense mechanical agitation. It operates by creating strong shear forces through high-speed rotating blades that break down particles and blend ingredients uniformly. This mixer is essential in pharmaceutical, cosmetic, and food industries for producing consistent, high-quality mixtures, especially in slurry and paste formulations.

What is a Fluid Bed Mixer?

A Fluid Bed Mixer is an advanced equipment used in pharmaceutical and chemical industries for drying, granulating, and mixing powders through a fluidization process. It efficiently suspends solid particles in an upward-moving stream of air, promoting uniform heat transfer and consistent blending. Compared to a High Shear Mixer, the Fluid Bed Mixer offers superior control over moisture content and particle size distribution during granulation.

Key Differences: High Shear Mixer vs Fluid Bed Mixer

High Shear Mixers utilize rapid rotation of impellers to generate intense shear forces for uniform wet granulation, while Fluid Bed Mixers rely on fluidization by hot air to dry and agglomerate particles through layering and binding. You should consider that High Shear Mixers are ideal for producing dense granules with shorter processing times, whereas Fluid Bed Mixers deliver better control over drying and particle size distribution. Key differences include the mixing mechanism, granule density, and process efficiency, which directly impact your choice depending on your formulation and production needs.

Working Principles of High Shear Mixers

High shear mixers operate by rapidly rotating blades that generate intense mechanical shear forces and turbulence to blend ingredients quickly and uniformly. The high-speed rotation creates a strong vortex, promoting efficient emulsification, dispersion, and granulation within the mixture. Understanding the working principles of high shear mixers helps optimize your industrial mixing processes for consistent product quality.

Working Principles of Fluid Bed Mixers

Fluid bed mixers operate by suspending particles in an upward-flowing air stream, creating a fluidized state that promotes uniform drying, granulation, and coating. This fluidization ensures efficient heat and mass transfer, enhancing mixing homogeneity and process speed. Your choice between a high shear mixer and a fluid bed mixer depends on whether you require intense mechanical agitation or gentle, aerodynamic mixing.

Applications: When to Use Each Mixer

High shear mixers are ideal for applications requiring rapid emulsification, homogenization, or particle size reduction, such as in pharmaceuticals, cosmetics, and food processing. Fluid bed mixers excel in drying, granulating, and coating powders, commonly used in the pharmaceutical and chemical industries for uniform particle treatment. Your choice depends on the need for intensive mixing and dispersion versus gentle drying and granulation processes.

Advantages and Disadvantages Comparison

High shear mixers offer superior particle size reduction and uniform blending, making them ideal for viscous materials and emulsions, but they consume more energy and may generate heat that can affect heat-sensitive products. Fluid bed mixers provide efficient drying and coating capabilities with gentle mixing, suited for heat-sensitive powders, yet they generally have lower mixing intensity and are less effective for highly viscous or cohesive materials. Both mixers have specific applications where their performance, energy consumption, and processing conditions align best with product requirements and production scale.

Energy Efficiency and Processing Time

High shear mixers typically consume more energy due to intense mechanical agitation, but they significantly reduce processing time by enabling rapid emulsification and dispersion. Fluid bed mixers offer superior energy efficiency by utilizing air flow for drying and mixing, making them ideal for heat-sensitive materials while generally requiring longer processing times. Your choice depends on balancing energy consumption with the need for quick processing in your production line.

Selecting the Right Mixer for Your Process

Choosing between a High Shear Mixer and a Fluid Bed Mixer depends on your process requirements such as mixing intensity, particle size distribution, and drying capabilities. High Shear Mixers excel in producing uniform wet granules through intense mixing and shear forces, ideal for formulations needing rapid, homogeneous blending. Fluid Bed Mixers combine mixing with drying in one step, making them efficient for granulation and drying of heat-sensitive materials, ensuring better process control and product quality.

High Shear Mixer vs Fluid Bed Mixer Infographic

libmatt.com

libmatt.com