Batch processing handles data or materials in discrete groups, making it ideal for variable production runs and easier quality control. Continuous processing operates without interruption, providing higher efficiency and consistent output for large-scale manufacturing, which can enhance Your overall production speed and cost-effectiveness.

Table of Comparison

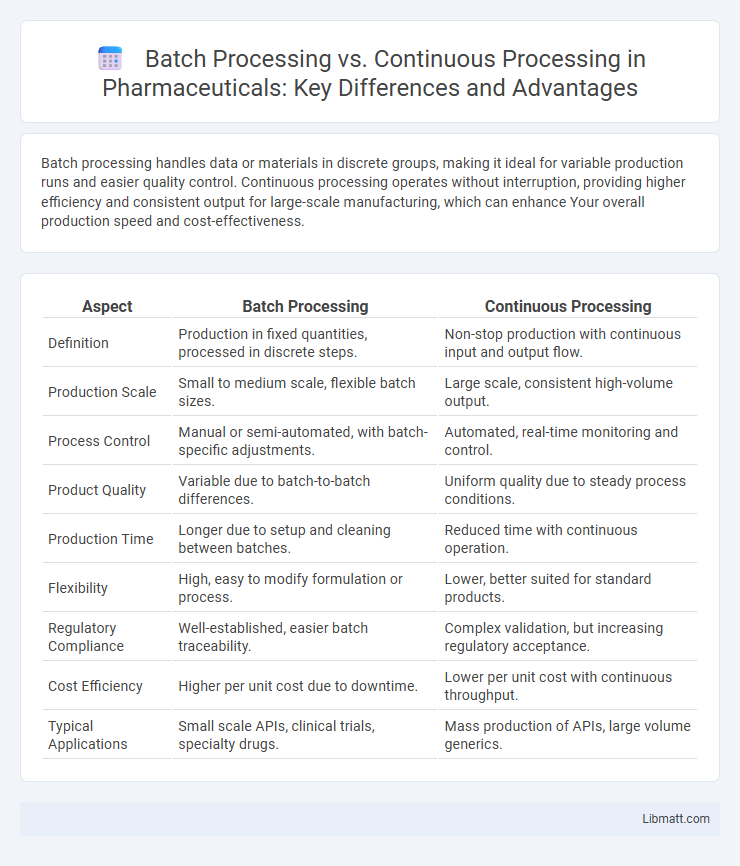

| Aspect | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Production in fixed quantities, processed in discrete steps. | Non-stop production with continuous input and output flow. |

| Production Scale | Small to medium scale, flexible batch sizes. | Large scale, consistent high-volume output. |

| Process Control | Manual or semi-automated, with batch-specific adjustments. | Automated, real-time monitoring and control. |

| Product Quality | Variable due to batch-to-batch differences. | Uniform quality due to steady process conditions. |

| Production Time | Longer due to setup and cleaning between batches. | Reduced time with continuous operation. |

| Flexibility | High, easy to modify formulation or process. | Lower, better suited for standard products. |

| Regulatory Compliance | Well-established, easier batch traceability. | Complex validation, but increasing regulatory acceptance. |

| Cost Efficiency | Higher per unit cost due to downtime. | Lower per unit cost with continuous throughput. |

| Typical Applications | Small scale APIs, clinical trials, specialty drugs. | Mass production of APIs, large volume generics. |

Introduction to Batch and Continuous Processing

Batch processing involves handling large volumes of data or materials in discrete, separate groups, making it ideal for tasks requiring precise control and flexibility. Continuous processing runs operations nonstop, optimizing efficiency and consistency by maintaining steady input and output streams. Understanding these methods helps you select the best approach for your production or data management needs based on scale, speed, and product uniformity.

Key Differences Between Batch and Continuous Processing

Batch processing handles materials in discrete, separate quantities, allowing for flexibility and customization in production runs, while continuous processing operates non-stop with a steady input and output stream ideal for high-volume manufacturing. Batch processing is often used in pharmaceuticals, specialty chemicals, and food industries where product variability is important, whereas continuous processing suits industries like oil refining and petrochemicals requiring constant production efficiency. Your choice between these methods depends on factors like production scale, product consistency, and process control requirements.

Advantages of Batch Processing

Batch processing enables efficient handling of large volumes of data or materials by processing them in groups, which reduces setup times and operational costs. It offers greater flexibility in managing production schedules and allows for easier quality control and fault isolation since errors can be detected and corrected before moving to the next batch. This method is ideal for industries requiring customization or varied product lines without interrupting the entire production flow.

Advantages of Continuous Processing

Continuous processing offers increased efficiency by enabling nonstop production, reducing downtime associated with batch changeovers. It provides consistent product quality through steady-state operations and real-time monitoring, minimizing variability and defects. This method also enhances scalability and is ideal for high-volume manufacturing, leading to lower operational costs and faster throughput.

Limitations of Batch Processing

Batch processing often faces limitations such as delayed data availability since information is processed in large, scheduled groups rather than in real time. This can result in slower response times and reduced agility in dynamic environments like manufacturing or data analytics. Additionally, error detection and correction are more challenging, as faults may not be identified until an entire batch has been processed, increasing downtime and rework costs.

Limitations of Continuous Processing

Continuous processing faces limitations such as reduced flexibility in handling product variations, making it less suitable for small production runs or customized products. The high initial capital investment and complex control systems can increase operational risks and maintenance costs. You may encounter challenges in quickly adjusting production parameters, which can impact efficiency and product quality.

Applications in Various Industries

Batch processing is widely used in industries such as pharmaceuticals, food production, and chemical manufacturing where discrete, large volumes of products are processed in stages. Continuous processing is predominant in sectors like oil refining, petrochemicals, and steel production, enabling nonstop material handling for higher efficiency and consistent output quality. Both processing methods optimize operational workflows by leveraging industry-specific requirements for product consistency, scalability, and resource management.

Factors Influencing Process Selection

Process selection between batch processing and continuous processing depends heavily on production volume, product uniformity, and flexibility requirements. Batch processing is preferred for low to medium volumes with varying product formulations, offering greater flexibility and easier quality control. Continuous processing suits high-volume, consistent products due to its efficiency, reduced labor costs, and steady output quality.

Cost Considerations and Efficiency

Batch processing often incurs higher initial setup costs due to the need for specialized equipment and downtime between batches, yet it offers flexibility in handling diverse product types. Continuous processing typically achieves greater efficiency by maintaining consistent operation and reducing labor costs, leading to lower production costs per unit over time. Cost considerations favor batch processing for small-scale or variable production, while continuous processing excels in large-scale, high-volume manufacturing environments.

Future Trends in Processing Technologies

Future trends in processing technologies emphasize the integration of advanced automation, AI, and real-time data analytics, driving a shift from traditional batch processing to more efficient continuous processing systems. Continuous processing offers enhanced scalability, reduced downtime, and improved product consistency, aligning with Industry 4.0 initiatives and sustainability goals. You can expect these innovations to optimize production yields and operational flexibility, propelling the manufacturing sector toward smarter, more adaptable workflows.

Batch processing vs Continuous processing Infographic

libmatt.com

libmatt.com