Spray dry granulation produces fine, uniform granules by rapidly drying liquid feed, enhancing flowability and solubility, making it ideal for heat-sensitive materials. Wet granulation involves mixing powders with a binder solution to form granules, improving compressibility and uniformity for tablets where moisture can be controlled effectively.

Table of Comparison

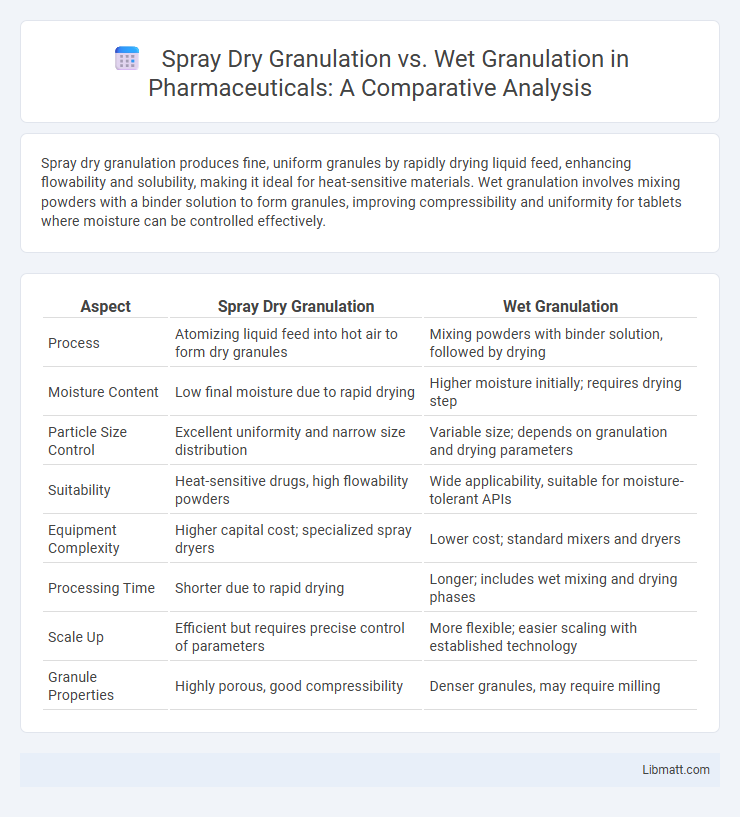

| Aspect | Spray Dry Granulation | Wet Granulation |

|---|---|---|

| Process | Atomizing liquid feed into hot air to form dry granules | Mixing powders with binder solution, followed by drying |

| Moisture Content | Low final moisture due to rapid drying | Higher moisture initially; requires drying step |

| Particle Size Control | Excellent uniformity and narrow size distribution | Variable size; depends on granulation and drying parameters |

| Suitability | Heat-sensitive drugs, high flowability powders | Wide applicability, suitable for moisture-tolerant APIs |

| Equipment Complexity | Higher capital cost; specialized spray dryers | Lower cost; standard mixers and dryers |

| Processing Time | Shorter due to rapid drying | Longer; includes wet mixing and drying phases |

| Scale Up | Efficient but requires precise control of parameters | More flexible; easier scaling with established technology |

| Granule Properties | Highly porous, good compressibility | Denser granules, may require milling |

Introduction to Granulation Techniques

Spray dry granulation and wet granulation are essential pharmaceutical techniques used to transform fine powders into granules for better flowability and compressibility. Spray dry granulation involves atomizing a liquid feed into hot air to rapidly dry and form granules, making it ideal for moisture-sensitive materials. Wet granulation uses a liquid binder to agglomerate powder particles, enhancing tablet uniformity and dissolution rates for your formulations.

Overview of Spray Dry Granulation

Spray dry granulation involves atomizing a liquid binder solution and sprayed onto a powder bed, instantly drying the droplets to form fine, consistent granules. This method enhances powder flowability and compressibility, making it ideal for pharmaceutical and food applications requiring uniform particle size and moisture control. The rapid drying process minimizes thermal degradation of heat-sensitive materials, ensuring product stability and quality.

Overview of Wet Granulation

Wet granulation involves the agglomeration of powder particles using a liquid binder to improve flowability and compressibility in pharmaceutical manufacturing. This process uses high-shear mixers or fluidized beds to form granules, which are then dried to achieve the desired moisture content. Wet granulation enhances uniformity in drug distribution and reduces dust generation compared to spray dry granulation.

Key Process Steps in Spray Dry Granulation

Spray dry granulation involves atomizing a liquid solution or slurry into fine droplets using a spray nozzle, which are then rapidly dried in a hot air chamber to form uniform granules. Key process steps include feed preparation, atomization, drying, and particle collection, ensuring controlled moisture content and particle size distribution. Your choice of spray dry granulation offers precise control over granule morphology and enhanced flow properties compared to traditional wet granulation.

Key Process Steps in Wet Granulation

Wet granulation involves the mixing of powders followed by the addition of a granulating liquid to form a wet mass, which is then screened or milled to produce granules. The wet granules are subsequently dried using fluidized bed dryers or tray dryers to remove moisture and achieve the desired granule hardness and flow properties. This process enhances powder compressibility and uniformity, critical for tablet production in pharmaceuticals.

Equipment and Technology Comparison

Spray dry granulation employs advanced spray dryers equipped with atomizers and heated air systems to transform liquid feed into fine, uniform granules rapidly, enhancing solubility and dispersibility. Wet granulation uses high-shear mixers or fluid bed granulators to combine powders with a binder solution, forming larger, denser granules suitable for compression and tablet formation. The spray drying equipment offers continuous processing with precise particle size control, whereas wet granulation relies on batch processing with flexibility in binder selection and moisture content adjustment.

Material Suitability and Formulation Aspects

Spray dry granulation excels in processing heat-sensitive materials due to its rapid drying technique, making it suitable for formulations with moisture-sensitive APIs and excipients. Wet granulation requires sufficient binding liquid, limiting its use for moisture-sensitive or thermolabile compounds but offers better control over granule density and size uniformity in formulations with lower solubility powders. Optimal material suitability depends on the formulation's thermal stability, moisture sensitivity, and desired granule properties, influencing the choice between spray dry and wet granulation methods.

Advantages of Spray Dry Granulation

Spray Dry Granulation offers superior particle uniformity and enhanced powder flow compared to wet granulation, making it ideal for producing consistent tablet weights and content uniformity in pharmaceuticals. This method reduces processing time by combining drying and granulation into a single step, leading to increased manufacturing efficiency and lower production costs. The resulting granules exhibit improved compressibility and solubility, beneficial for creating high-quality solid dosage forms with enhanced bioavailability.

Advantages of Wet Granulation

Wet granulation enhances powder flow properties and improves compressibility, resulting in tablets with better mechanical strength and uniformity. It effectively reduces dust generation and segregation during processing, which contributes to consistent drug distribution and dosage accuracy. This method also allows for the use of diverse binder solutions, offering flexibility in formulation to optimize product stability and release profiles.

Choosing the Right Granulation Method

Choosing the right granulation method depends on your formulation goals, equipment availability, and product characteristics. Spray dry granulation offers uniform particle size and enhanced flowability, ideal for heat-sensitive and moisture-sensitive materials, while wet granulation improves compressibility and is suitable for formulations requiring binder solutions. Evaluating factors such as drying time, cost-effectiveness, and desired granule properties helps ensure optimal performance and manufacturing efficiency.

Spray Dry Granulation vs Wet Granulation Infographic

libmatt.com

libmatt.com