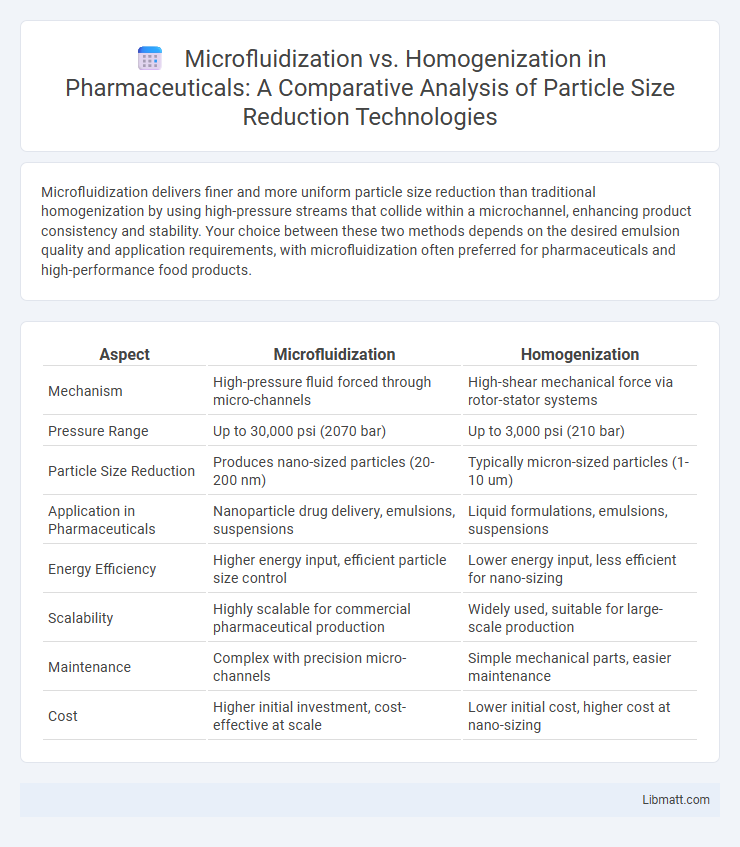

Microfluidization delivers finer and more uniform particle size reduction than traditional homogenization by using high-pressure streams that collide within a microchannel, enhancing product consistency and stability. Your choice between these two methods depends on the desired emulsion quality and application requirements, with microfluidization often preferred for pharmaceuticals and high-performance food products.

Table of Comparison

| Aspect | Microfluidization | Homogenization |

|---|---|---|

| Mechanism | High-pressure fluid forced through micro-channels | High-shear mechanical force via rotor-stator systems |

| Pressure Range | Up to 30,000 psi (2070 bar) | Up to 3,000 psi (210 bar) |

| Particle Size Reduction | Produces nano-sized particles (20-200 nm) | Typically micron-sized particles (1-10 um) |

| Application in Pharmaceuticals | Nanoparticle drug delivery, emulsions, suspensions | Liquid formulations, emulsions, suspensions |

| Energy Efficiency | Higher energy input, efficient particle size control | Lower energy input, less efficient for nano-sizing |

| Scalability | Highly scalable for commercial pharmaceutical production | Widely used, suitable for large-scale production |

| Maintenance | Complex with precision micro-channels | Simple mechanical parts, easier maintenance |

| Cost | Higher initial investment, cost-effective at scale | Lower initial cost, higher cost at nano-sizing |

Introduction to Microfluidization and Homogenization

Microfluidization and homogenization are advanced techniques used to reduce particle size and improve emulsion stability in pharmaceuticals, food, and cosmetics. Microfluidization employs high-pressure streams forced through micro-channels, generating intense shear, impact, and cavitation forces for uniform particle size distribution. Homogenization uses mechanical pressure to break down particles by forcing the mixture through narrow gaps, enhancing texture and consistency in your formulations.

Principles and Mechanisms of Microfluidization

Microfluidization operates by forcing fluids through microchannels at extremely high pressures, utilizing fixed-geometry microchannels to create intense shear, impact, and cavitation forces that reduce particle size and enhance mixing efficiency. Unlike traditional homogenization, which relies on high-pressure valves and turbulent flow, microfluidization achieves more uniform and finer emulsions due to its controlled jet-stream interactions within the microchannels. This technology improves product stability, bioavailability, and texture in pharmaceutical, food, and cosmetic applications by optimizing droplet size distribution at the micron and nanometer scales.

How Homogenization Works: Key Concepts

Homogenization works by forcing a fluid through a narrow gap at high pressure, causing intense shear, turbulence, and cavitation that break down particles and droplets into smaller, uniform sizes. This process reduces particle size and improves product stability, texture, and homogeneity in applications like dairy, pharmaceuticals, and cosmetics. Key factors influencing homogenization include pressure level, temperature, and the design of the homogenizer valve.

Equipment Design: Microfluidizers vs. Homogenizers

Microfluidizers utilize fixed-geometry interaction chambers where fluid streams collide at high velocity, ensuring uniform particle size reduction through controlled shear and impact forces. Homogenizers typically feature a valve-type design where fluid is forced through a narrow gap under high pressure, generating turbulence and shear to reduce particle size but with less precision. The microfluidizer's design enables consistent, scalable processing with enhanced control over particle size distribution compared to traditional homogenizers, making it ideal for applications requiring fine emulsions or suspensions.

Particle Size Reduction Efficiency

Microfluidization achieves superior particle size reduction efficiency by employing high-pressure streams that collide at ultra-high velocities, resulting in smaller and more uniform particle sizes compared to traditional homogenization. This method consistently produces nano-sized emulsions with particle diameters typically below 200 nanometers, enhancing stability and bioavailability in pharmaceutical and food applications. Homogenization, while effective for larger particles, often results in broader size distributions and less uniformity, limiting its efficiency in applications requiring precise nanoparticle control.

Applications in Pharmaceuticals and Food Industry

Microfluidization and homogenization both play critical roles in pharmaceuticals and food industries by enhancing product stability and bioavailability through particle size reduction. Microfluidization offers superior control over particle size distribution, leading to more consistent emulsions and suspensions essential for drug delivery systems and functional food formulations. Your choice between these technologies depends on the required product texture, stability, and scalability in manufacturing.

Product Quality and Stability Differences

Microfluidization generates smaller, more uniform particle sizes compared to traditional homogenization, resulting in enhanced product quality with smoother texture and improved mouthfeel. The high shear forces in microfluidization promote better stability by creating more stable emulsions and reducing phase separation over time. These differences lead to longer shelf life and consistent performance in pharmaceuticals, food, and cosmetic formulations.

Energy Consumption and Operational Costs

Microfluidization typically requires less energy per volume of fluid processed compared to traditional homogenization due to its efficient interaction chamber design, resulting in lower operational costs over time. The high-pressure pumps in microfluidizers consume energy more effectively, providing finer particle size reduction and consistent product quality, which can reduce waste and reprocessing expenses. Your choice between microfluidization and homogenization will impact overall energy consumption and cost-efficiency depending on specific production scale and product requirements.

Maintenance, Scalability, and Ease of Use

Microfluidization offers precise control over particle size with relatively low maintenance due to fewer moving parts, making it scalable for both laboratory and industrial production. Homogenization, while easier to operate with straightforward mechanisms, often requires more frequent maintenance because of wear on valves and seals, limiting its long-term scalability. Your choice depends on balancing the ease of use in operation against maintenance demands and the scalability needs of your process.

Choosing the Right Technology: Factors to Consider

Selecting between microfluidization and homogenization depends on factors such as desired particle size reduction, sample viscosity, and processing volume. Microfluidization offers superior uniformity and finer emulsions ideal for pharmaceuticals and high-value products, while homogenization suits larger volumes with moderate size reduction needs. Cost considerations, equipment maintenance, and end-product quality requirements also play crucial roles in determining the optimal technology for specific applications.

Microfluidization vs Homogenization Infographic

libmatt.com

libmatt.com