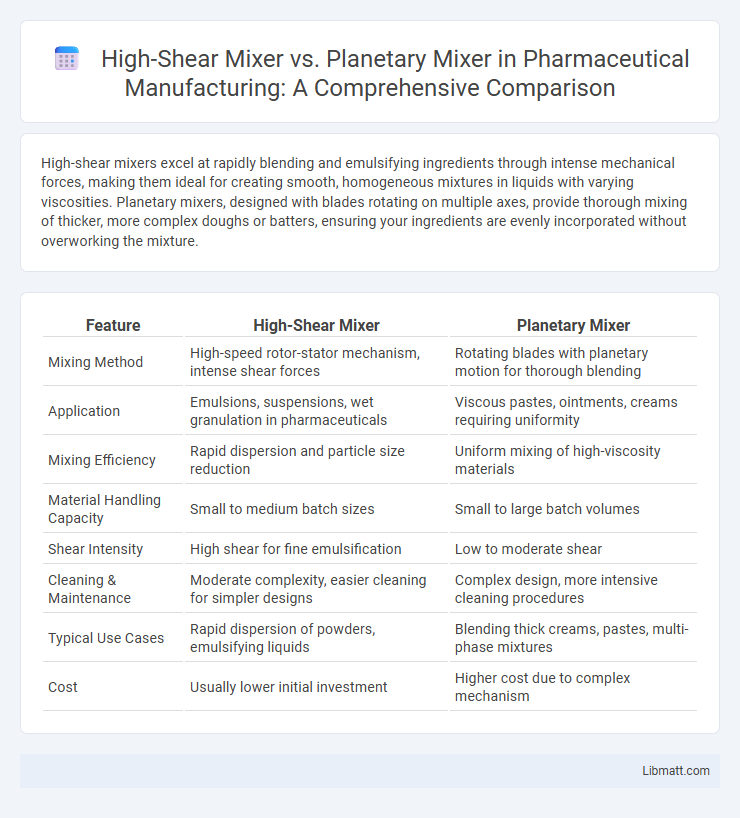

High-shear mixers excel at rapidly blending and emulsifying ingredients through intense mechanical forces, making them ideal for creating smooth, homogeneous mixtures in liquids with varying viscosities. Planetary mixers, designed with blades rotating on multiple axes, provide thorough mixing of thicker, more complex doughs or batters, ensuring your ingredients are evenly incorporated without overworking the mixture.

Table of Comparison

| Feature | High-Shear Mixer | Planetary Mixer |

|---|---|---|

| Mixing Method | High-speed rotor-stator mechanism, intense shear forces | Rotating blades with planetary motion for thorough blending |

| Application | Emulsions, suspensions, wet granulation in pharmaceuticals | Viscous pastes, ointments, creams requiring uniformity |

| Mixing Efficiency | Rapid dispersion and particle size reduction | Uniform mixing of high-viscosity materials |

| Material Handling Capacity | Small to medium batch sizes | Small to large batch volumes |

| Shear Intensity | High shear for fine emulsification | Low to moderate shear |

| Cleaning & Maintenance | Moderate complexity, easier cleaning for simpler designs | Complex design, more intensive cleaning procedures |

| Typical Use Cases | Rapid dispersion of powders, emulsifying liquids | Blending thick creams, pastes, multi-phase mixtures |

| Cost | Usually lower initial investment | Higher cost due to complex mechanism |

Introduction to High-Shear and Planetary Mixers

High-shear mixers utilize high rotational speeds and intense shear forces to rapidly blend, emulsify, and homogenize viscous and complex materials, making them ideal for pharmaceutical, cosmetic, and food applications. Planetary mixers feature multiple mixing blades rotating on their own axes while simultaneously orbiting the central axis, ensuring thorough mixing of thick, dense, or multi-component materials commonly used in bakery, chemical, and construction industries. Understanding the operational principles and application-specific advantages of high-shear and planetary mixers enables optimal selection based on product viscosity, mixing speed, and batch size requirements.

How High-Shear Mixers Work

High-shear mixers operate by rapidly rotating rotor blades within a stationary stator, creating intense hydraulic shear forces that break down particles and emulsify ingredients efficiently. This high-speed shear action promotes uniform mixing and rapid dispersion, making them ideal for inks, paints, pharmaceuticals, and food products requiring fine particle size reduction and consistent texture. Unlike planetary mixers that use rotating bowls and agitators for bulk blending, high-shear mixers target micro-level mixing through powerful rotor-stator mechanics.

Planetary Mixers: Operating Principles

Planetary mixers operate using a rotating agitator that revolves around a stationary bowl, providing thorough blending by ensuring intense mixing action in all directions. The agitator rotates on its own axis while simultaneously orbiting the bowl, mimicking the motion of planets, which enhances uniform ingredient incorporation. This dual-motion mechanism is ideal for processing viscous materials and achieving consistent texture in doughs, creams, and pastes.

Key Differences Between High-Shear and Planetary Mixers

High-shear mixers generate intense shear forces using rapidly rotating blades to achieve emulsification, dispersion, and homogenization, making them ideal for producing fine, uniform mixtures in industries like pharmaceuticals and cosmetics. Planetary mixers feature blades rotating on multiple axes that sweep the container thoroughly, enabling efficient mixing of viscous materials and doughs commonly used in food and chemical processing. The primary difference lies in the mixing mechanism and shear intensity: high-shear mixers excel at breaking down particles and creating stable emulsions, while planetary mixers provide thorough, consistent mixing of thicker pastes and viscous substances.

Typical Applications for High-Shear Mixers

High-shear mixers are commonly used in industries such as pharmaceuticals, cosmetics, and food processing for emulsifying, homogenizing, and dispersing ingredients with high viscosity or requiring fine particle size reduction. They excel in producing stable emulsions, suspensions, and dispersions, particularly for creams, lotions, sauces, and adhesives. Their rapid mixing capability and efficient shear force make them ideal for processes that demand uniform texture and consistency at a large scale.

Common Uses of Planetary Mixers

Planetary mixers are commonly used in bakeries and commercial kitchens for mixing dough, batter, and frosting due to their versatile mixing action that ensures uniform consistency. Their unique planetary motion allows attachments like beaters, whisks, and dough hooks to efficiently handle thick and dense mixtures. You can rely on planetary mixers for precise and thorough blending in applications requiring gentle to heavy-duty mixing tasks.

Performance Comparison: Mixing Speed and Efficiency

High-shear mixers deliver rapid mixing speeds by utilizing intense shear forces to break down particles quickly, making them highly efficient for emulsification and dispersion processes. Planetary mixers rotate both the mixing tool and the container, offering thorough blending ideal for viscous materials but generally operating at slower speeds compared to high-shear mixers. The choice between the two depends on the specific application, with high-shear mixers excelling in speed and efficiency for liquid and semi-liquid mixtures, while planetary mixers provide superior uniformity for thick, complex formulations.

Product Quality and Consistency Analysis

High-shear mixers deliver superior product quality by ensuring uniform particle size reduction and homogeneous mixing through intense shear forces, ideal for emulsions and suspensions. Planetary mixers provide consistent batch-to-batch mixing by combining planetary rotation and individual agitator movements, which excel in blending viscous and complex formulations. Comparative analysis reveals high-shear mixers achieve finer dispersion and faster processing, while planetary mixers offer enhanced control over texture and viscosity consistency.

Factors to Consider When Choosing a Mixer

Choosing between a high-shear mixer and a planetary mixer depends largely on your material viscosity, batch size, and desired mixing intensity. High-shear mixers excel in emulsification and particle size reduction for low to medium viscosity fluids, while planetary mixers handle high-viscosity, thick materials requiring thorough shear and folding action. Your decision should prioritize the mixer's power, speed control, and blade design to ensure efficient mixing and product consistency.

Conclusion: Which Mixer is Right for Your Process?

High-shear mixers provide rapid dispersion and emulsification suited for liquid-liquid or liquid-solid applications requiring intense mixing and particle size reduction. Planetary mixers excel in handling high-viscosity, dough-like materials with thorough, uniform mixing through their complex rotational movements. Choosing the right mixer depends on the material properties and process requirements, with high-shear mixers favored for emulsions and suspensions, while planetary mixers suit heavy pastes and viscous blends.

High-shear mixer vs planetary mixer Infographic

libmatt.com

libmatt.com