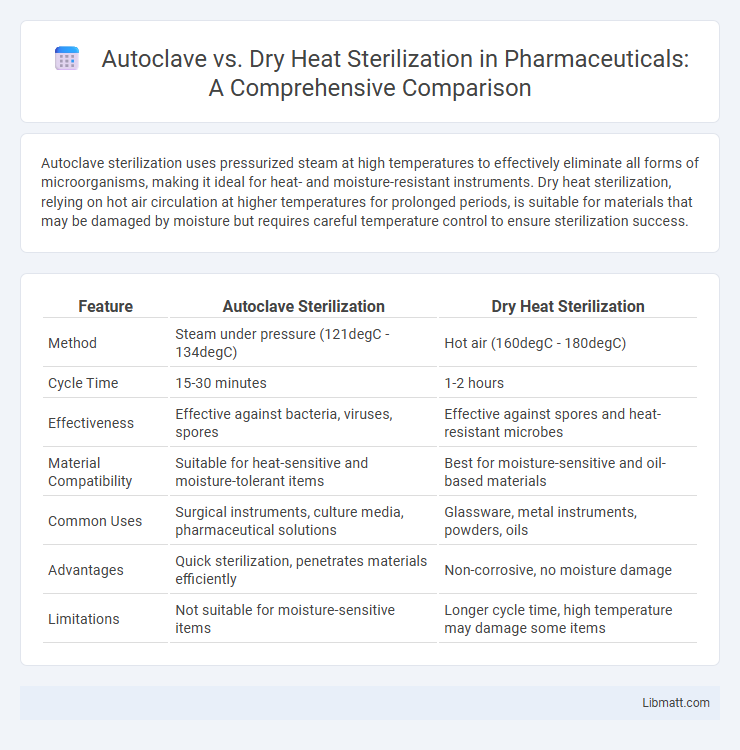

Autoclave sterilization uses pressurized steam at high temperatures to effectively eliminate all forms of microorganisms, making it ideal for heat- and moisture-resistant instruments. Dry heat sterilization, relying on hot air circulation at higher temperatures for prolonged periods, is suitable for materials that may be damaged by moisture but requires careful temperature control to ensure sterilization success.

Table of Comparison

| Feature | Autoclave Sterilization | Dry Heat Sterilization |

|---|---|---|

| Method | Steam under pressure (121degC - 134degC) | Hot air (160degC - 180degC) |

| Cycle Time | 15-30 minutes | 1-2 hours |

| Effectiveness | Effective against bacteria, viruses, spores | Effective against spores and heat-resistant microbes |

| Material Compatibility | Suitable for heat-sensitive and moisture-tolerant items | Best for moisture-sensitive and oil-based materials |

| Common Uses | Surgical instruments, culture media, pharmaceutical solutions | Glassware, metal instruments, powders, oils |

| Advantages | Quick sterilization, penetrates materials efficiently | Non-corrosive, no moisture damage |

| Limitations | Not suitable for moisture-sensitive items | Longer cycle time, high temperature may damage some items |

Introduction to Sterilization Methods

Autoclave sterilization uses pressurized steam at temperatures of 121-134degC to effectively eliminate microorganisms, including spores, within 15-30 minutes. Dry heat sterilization employs hot air at higher temperatures, typically 160-180degC, for extended periods ranging from 1 to 2 hours, making it suitable for materials that moisture can damage. Both methods ensure sterilization but differ in mechanism, temperature, exposure time, and material compatibility.

Overview of Autoclave Sterilization

Autoclave sterilization utilizes high-pressure saturated steam at temperatures of 121-134degC to effectively eliminate microorganisms, including spores, on surgical instruments and laboratory equipment. This method ensures rapid penetration and sterilization, making it a reliable choice for heat- and moisture-stable items. Your medical or lab tools retain sterility for safe use, supported by autoclave's proven efficiency and regulatory compliance.

Overview of Dry Heat Sterilization

Dry heat sterilization uses high temperatures, typically between 160degC and 180degC, maintained for extended periods to destroy microorganisms by oxidation. This method is ideal for sterilizing substances that might be damaged by moisture, such as powders, oils, and metal instruments. Your choice between autoclave and dry heat sterilization depends on the material compatibility and the specific sterilization requirements of your tools or products.

Mechanism of Action: Autoclave vs Dry Heat

Autoclave sterilization uses pressurized steam at high temperatures (typically 121-134degC) to denature proteins and destroy microbial cells rapidly. Dry heat sterilization operates at higher temperatures (usually 160-180degC) for longer durations, causing oxidative damage and protein denaturation by dehydration. Understanding these mechanisms helps you choose the appropriate method for sterilizing heat-sensitive or moisture-sensitive instruments efficiently.

Applications in Medical and Laboratory Settings

Autoclave sterilization uses pressurized steam to effectively eliminate bacteria, viruses, and spores, making it ideal for sterilizing surgical instruments, laboratory glassware, and media preparation in medical and research environments. Dry heat sterilization relies on hot air to kill microorganisms, suitable for heat-resistant items like metal instruments, powders, and oils where moisture can cause damage. Your choice between autoclave and dry heat depends on the material compatibility and sterilization requirements of your medical or laboratory equipment.

Advantages of Autoclave Sterilization

Autoclave sterilization offers rapid and effective microbial elimination by utilizing high-pressure saturated steam at temperatures around 121-134degC, ensuring comprehensive sterilization of surgical instruments and laboratory equipment. It effectively destroys spores and resistant microorganisms, making it suitable for heat- and moisture-tolerant items while maintaining material integrity. Its ability to penetrate packaging materials and uniform heat distribution reduces the risk of contamination, providing a reliable sterilization method in medical and research environments.

Advantages of Dry Heat Sterilization

Dry heat sterilization offers several advantages, including the ability to effectively sterilize moisture-sensitive instruments and materials without causing corrosion or rust. It requires less maintenance compared to autoclaves, as there is no need for water or steam, reducing the risk of equipment failure. Dry heat sterilizers also provide uniform temperature distribution, making them ideal for glassware, powders, and oils that cannot withstand wet heat.

Limitations and Drawbacks of Each Method

Autoclave sterilization, while highly effective against a broad spectrum of microorganisms, can damage heat-sensitive instruments and is unsuitable for materials that cannot withstand high temperature and moisture. Dry heat sterilization requires longer exposure times and higher temperatures, making it less efficient and potentially causing oxidative damage to delicate instruments. Your choice between these methods should consider the compatibility of the sterilization process with the specific materials and operational constraints of your practice.

Efficiency and Effectiveness Comparison

Autoclave sterilization achieves higher efficiency by using pressurized steam at temperatures of 121-134degC, effectively eliminating all forms of microbial life, including spores, within 15-30 minutes. Dry heat sterilization requires longer exposure times, typically 1-2 hours at 160-180degC, to attain similar microbial kill rates, making it less time-efficient but suitable for heat-resistant instruments. Autoclaving ensures superior penetration and faster microbial reduction, while dry heat is preferred for moisture-sensitive materials despite its lower overall sterilization speed.

Choosing the Right Sterilization Method

Choosing the right sterilization method depends on the type of instruments and materials involved; autoclave sterilization uses pressurized steam to effectively kill microorganisms and is ideal for heat-resistant surgical tools and lab equipment. Dry heat sterilization applies high temperatures over longer periods without moisture, making it suitable for metal instruments, powders, and oils that could be damaged by moisture. Your selection should consider factors such as heat sensitivity, material compatibility, and the required sterilization cycle time to ensure optimal safety and efficacy.

Autoclave vs Dry heat sterilization Infographic

libmatt.com

libmatt.com