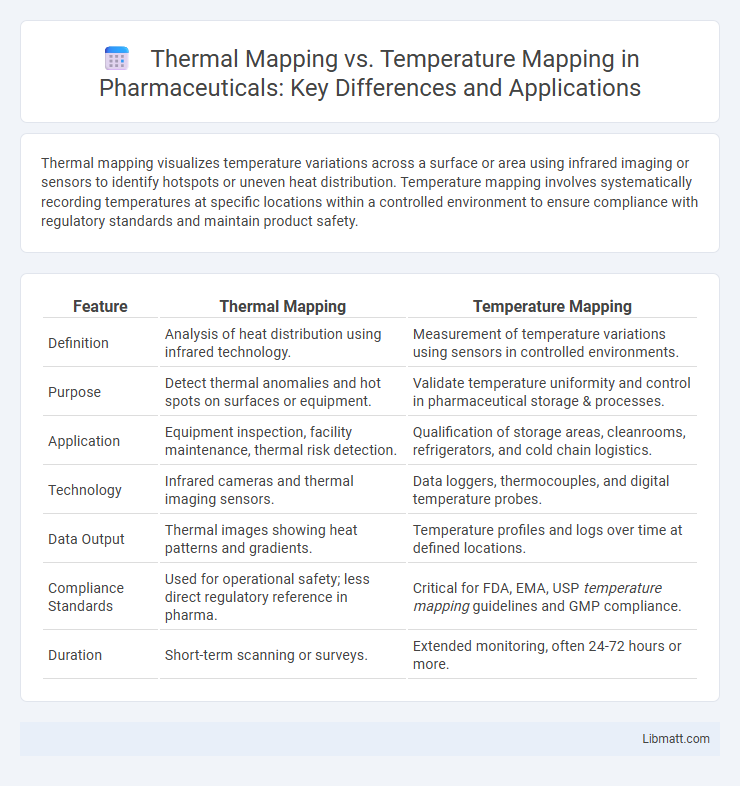

Thermal mapping visualizes temperature variations across a surface or area using infrared imaging or sensors to identify hotspots or uneven heat distribution. Temperature mapping involves systematically recording temperatures at specific locations within a controlled environment to ensure compliance with regulatory standards and maintain product safety.

Table of Comparison

| Feature | Thermal Mapping | Temperature Mapping |

|---|---|---|

| Definition | Analysis of heat distribution using infrared technology. | Measurement of temperature variations using sensors in controlled environments. |

| Purpose | Detect thermal anomalies and hot spots on surfaces or equipment. | Validate temperature uniformity and control in pharmaceutical storage & processes. |

| Application | Equipment inspection, facility maintenance, thermal risk detection. | Qualification of storage areas, cleanrooms, refrigerators, and cold chain logistics. |

| Technology | Infrared cameras and thermal imaging sensors. | Data loggers, thermocouples, and digital temperature probes. |

| Data Output | Thermal images showing heat patterns and gradients. | Temperature profiles and logs over time at defined locations. |

| Compliance Standards | Used for operational safety; less direct regulatory reference in pharma. | Critical for FDA, EMA, USP temperature mapping guidelines and GMP compliance. |

| Duration | Short-term scanning or surveys. | Extended monitoring, often 24-72 hours or more. |

Introduction to Thermal Mapping and Temperature Mapping

Thermal mapping involves using infrared technology to capture surface temperature variations across large areas, enabling the identification of heat losses or hotspots. Temperature mapping, on the other hand, focuses on monitoring specific points within controlled environments to ensure compliance with temperature-sensitive processes. Understanding the distinction helps you optimize thermal management by selecting the appropriate technique for your operational needs.

Definition: Thermal Mapping Explained

Thermal mapping involves creating a visual representation of temperature distribution across a surface or area using advanced infrared technology, capturing real-time thermal variations. Temperature mapping, on the other hand, focuses on systematically recording temperature data at specific locations over a set period to ensure conditions meet required standards. Understanding the distinction between thermal mapping and temperature mapping helps you select the appropriate method for accurately monitoring thermal environments in industries such as pharmaceuticals and food storage.

Definition: Temperature Mapping Explained

Temperature mapping is the systematic process of measuring and recording temperature data within a controlled environment, such as a pharmaceutical storage area, to ensure consistent conditions and regulatory compliance. It involves placing sensors at multiple locations to identify temperature variations and validate equipment performance. Thermal mapping, while similar, often emphasizes broader heat distribution analysis across larger or more complex systems.

Key Differences Between Thermal and Temperature Mapping

Thermal mapping involves creating visual representations of temperature distribution across surfaces or spaces using infrared cameras, providing detailed thermal gradients and hot spot identification. Temperature mapping, by contrast, systematically records temperature values at specific points over time using sensors or data loggers to verify temperature uniformity and stability in controlled environments. The key differences lie in thermal mapping's spatial visualization capabilities versus temperature mapping's temporal monitoring for compliance and process validation.

Technologies Used in Thermal vs Temperature Mapping

Thermal mapping primarily employs infrared thermography and thermal imaging cameras to capture temperature distributions over surfaces or environments in real-time, enabling non-contact, spatial temperature analysis. Temperature mapping typically uses an array of calibrated thermocouples, resistance temperature detectors (RTDs), or data loggers strategically placed to record precise point temperatures within controlled environments like pharmaceutical chambers. The key technological distinction lies in thermal mapping's reliance on infrared sensors for visual heat pattern analysis versus temperature mapping's dependence on sensor arrays for detailed temporal temperature profiling.

Applications of Thermal Mapping

Thermal mapping is widely used in environmental monitoring, industrial process control, and building energy audits to visualize temperature variations across large surfaces or areas. It provides comprehensive spatial data essential for detecting heat loss, identifying hotspots in electrical equipment, and optimizing HVAC systems for energy efficiency. This technique supports proactive maintenance and enhances safety by revealing thermal anomalies that could indicate potential failures.

Applications of Temperature Mapping

Temperature mapping is primarily used in pharmaceutical and food industries to validate storage conditions of sensitive products within refrigerators, freezers, and storage rooms, ensuring compliance with regulatory standards such as FDA and WHO guidelines. It identifies temperature variations and hotspots by placing sensors at multiple points over extended periods, supporting risk assessment and quality assurance in cold chain management. This process is crucial for maintaining product efficacy and safety during storage and transportation.

Benefits and Limitations of Each Method

Thermal mapping provides real-time, spatial visualization of temperature distribution using infrared cameras, enabling rapid identification of hotspots and cold zones, which benefits process control but may lack precise temperature accuracy. Temperature mapping involves placing calibrated sensors throughout a controlled environment, offering detailed, accurate temperature profiles essential for validation and regulatory compliance, though it is time-consuming and less suited for dynamic changes. Each method's limitation is offset by the other's strengths, making thermal mapping ideal for quick assessments and temperature mapping critical for thorough validation.

Industry Standards and Regulatory Requirements

Thermal mapping and temperature mapping are critical processes guided by stringent industry standards such as ISO 14644 and FDA 21 CFR Part 11, ensuring consistent environmental control in pharmaceutical and food manufacturing. Temperature mapping involves detailed documentation of temperature distribution over time, while thermal mapping typically includes combined temperature and humidity data to meet regulatory requirements for storage and transportation environments. Compliance with these standards guarantees product safety, efficacy, and quality throughout the cold chain and controlled environments.

Choosing the Right Mapping Method for Your Needs

Thermal mapping involves continuous monitoring of surface or ambient temperatures using infrared technology to identify hot spots or thermal variations, ideal for real-time analysis and quick diagnostics. Temperature mapping relies on strategically placing sensors or data loggers to record temperature fluctuations over a specified period, providing detailed historical data crucial for validating environmental conditions in controlled settings. Choosing the right mapping method depends on whether you need immediate thermal profiles or long-term temperature stability assessments, ensuring compliance with industry standards like USP <1079> or ISO 14644 series.

Thermal mapping vs Temperature mapping Infographic

libmatt.com

libmatt.com