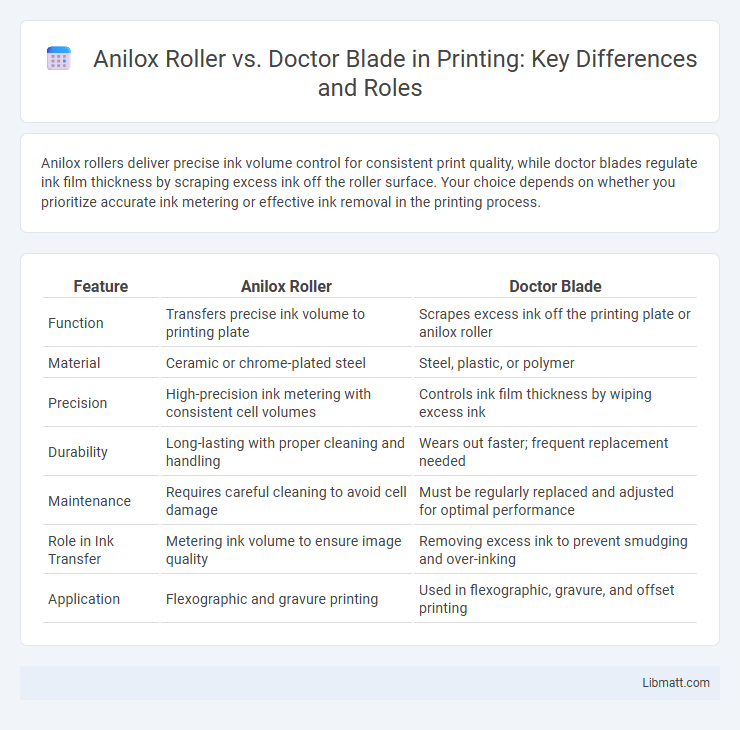

Anilox rollers deliver precise ink volume control for consistent print quality, while doctor blades regulate ink film thickness by scraping excess ink off the roller surface. Your choice depends on whether you prioritize accurate ink metering or effective ink removal in the printing process.

Table of Comparison

| Feature | Anilox Roller | Doctor Blade |

|---|---|---|

| Function | Transfers precise ink volume to printing plate | Scrapes excess ink off the printing plate or anilox roller |

| Material | Ceramic or chrome-plated steel | Steel, plastic, or polymer |

| Precision | High-precision ink metering with consistent cell volumes | Controls ink film thickness by wiping excess ink |

| Durability | Long-lasting with proper cleaning and handling | Wears out faster; frequent replacement needed |

| Maintenance | Requires careful cleaning to avoid cell damage | Must be regularly replaced and adjusted for optimal performance |

| Role in Ink Transfer | Metering ink volume to ensure image quality | Removing excess ink to prevent smudging and over-inking |

| Application | Flexographic and gravure printing | Used in flexographic, gravure, and offset printing |

Introduction to Anilox Rollers and Doctor Blades

Anilox rollers are precision ceramic-coated cylinders designed to deliver consistent ink volume for high-quality printing, ensuring accurate ink transfer in flexographic processes. Doctor blades function by scraping excess ink from the anilox roller, maintaining a uniform ink film thickness essential for crisp, clear print output. Understanding the role of your anilox roller and doctor blade in tandem helps optimize print quality and reduces waste in your production workflow.

Core Functions in the Printing Process

Anilox rollers precisely control the amount of ink transferred onto the printing plate, ensuring consistent ink film thickness for high-quality prints. Doctor blades remove excess ink from the anilox roller surface, maintaining uniform ink distribution and preventing smudging or defects. Understanding the core functions of these components helps you optimize print clarity, color accuracy, and overall production efficiency.

Material Composition and Durability

Anilox rollers are primarily made from ceramic or chrome-coated steel, offering exceptional hardness and wear resistance that ensures consistent ink transfer over long production runs. Doctor blades are typically manufactured from stainless steel or polymer, designed for flexibility and precise ink metering but prone to faster wear compared to ceramic anilox surfaces. The ceramic composition of anilox rollers provides superior durability in harsh printing environments, whereas doctor blades require regular replacement to maintain print quality.

Precision in Ink Metering

Anilox rollers provide exceptional precision in ink metering by delivering a consistent volume of ink through engraved cells, ensuring uniform ink distribution on the printing plate. Doctor blades complement this process by scraping off excess ink from the anilox surface, fine-tuning the ink layer and preventing smudging or ink waste. Your printing quality depends heavily on the balance between anilox roller cell volume and doctor blade pressure for accurate and efficient ink transfer.

Common Types and Variations

Anilox rollers commonly come in ceramic and chrome surfaces, with variations like hard-anodized aluminum for specific ink transfer needs, featuring different cell volumes and line screen densities to control ink film thickness. Doctor blades are typically classified into steel, plastic, and composite materials, with variations including flexible, rigid, and segmented blades designed to suit various printing speeds and ink types. Both anilox rollers and doctor blades offer customizable configurations to optimize print quality and durability in flexographic printing processes.

Maintenance and Cleaning Requirements

Anilox rollers require meticulous cleaning with specialized solvents to prevent ink clogging in their tiny cells, ensuring consistent print quality and longevity. Doctor blades demand frequent inspection and replacement to avoid wear-related defects such as streaking, which can compromise print accuracy. Proper maintenance of both components is essential for your printing press's optimal performance and minimal downtime.

Cost Considerations and Lifecycle

Anilox rollers typically have higher upfront costs due to precision engraving and materials but offer a longer lifecycle of 3 to 5 years with proper maintenance, reducing replacement frequency. Doctor blades are more affordable initially but require frequent replacement and disposal, increasing ongoing operational costs. Your cost efficiency depends on balancing the durable investment of anilox rollers against the recurring expenses of doctor blades.

Impact on Print Quality and Consistency

Anilox rollers provide precise ink metering by controlling the volume of ink transferred to the printing plate, ensuring consistent color density and sharp image reproduction. Doctor blades maintain uniform ink film thickness on the anilox surface by scraping excess ink, preventing streaks and smudges that could degrade print quality. The combined performance of anilox rollers and doctor blades directly influences print consistency, with wear or damage to either component causing noticeable variations in output.

Troubleshooting Common Issues

Anilox rollers often face common issues like ink starvation, streaking, or uneven ink distribution caused by improper cleaning or damaged cells, requiring precise inspection and cleaning techniques to maintain optimal print quality. Doctor blades frequently encounter problems such as edge wear, streaks, or ink build-up, which necessitate regular blade replacement and correct pressure adjustment to ensure consistent ink metering. Troubleshooting both components involves monitoring wear patterns, ensuring compatibility with ink types, and maintaining equipment to prevent downtime and achieve high-definition printing results.

Choosing the Right Solution for Your Press

Selecting the right solution for your press depends on factors like print quality, maintenance, and cost efficiency. Anilox rollers provide consistent ink metering and improved print precision, ideal for high-volume and detailed applications. Doctor blades offer easier maintenance and lower upfront costs, making them suitable for smaller runs or less demanding print environments.

Anilox roller vs doctor blade Infographic

libmatt.com

libmatt.com