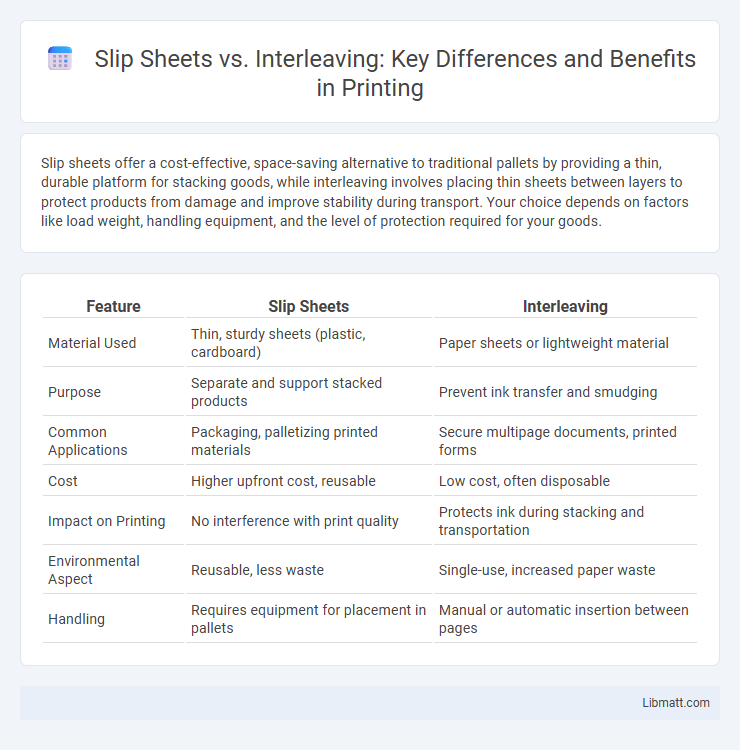

Slip sheets offer a cost-effective, space-saving alternative to traditional pallets by providing a thin, durable platform for stacking goods, while interleaving involves placing thin sheets between layers to protect products from damage and improve stability during transport. Your choice depends on factors like load weight, handling equipment, and the level of protection required for your goods.

Table of Comparison

| Feature | Slip Sheets | Interleaving |

|---|---|---|

| Material Used | Thin, sturdy sheets (plastic, cardboard) | Paper sheets or lightweight material |

| Purpose | Separate and support stacked products | Prevent ink transfer and smudging |

| Common Applications | Packaging, palletizing printed materials | Secure multipage documents, printed forms |

| Cost | Higher upfront cost, reusable | Low cost, often disposable |

| Impact on Printing | No interference with print quality | Protects ink during stacking and transportation |

| Environmental Aspect | Reusable, less waste | Single-use, increased paper waste |

| Handling | Requires equipment for placement in pallets | Manual or automatic insertion between pages |

Introduction to Slip Sheets and Interleaving

Slip sheets and interleaving serve as efficient alternatives to traditional palletizing methods in material handling and logistics. Slip sheets are thin, durable sheets made from plastic or fiberboard placed between layers of products to provide separation and stability during transport, while interleaving involves inserting material sheets such as cardboard or film between individual items to prevent surface damage and contamination. Your choice between slip sheets and interleaving depends on product type, handling equipment, and cost-effectiveness, optimizing protection and load integrity.

What are Slip Sheets?

Slip sheets are thin, rigid sheets typically made of cardboard or plastic used as an alternative to traditional wooden pallets for unitizing and stabilizing loads during shipping and storage. They serve as a base layer between stacked products, enabling forklifts with specialized attachments to handle entire loads efficiently while reducing shipping weight and pallet costs. Slip sheets improve warehouse space utilization by minimizing load height and allow for easier product separation compared to wooden pallets.

What is Interleaving?

Interleaving is a packaging technique that involves placing a layer of protective material, such as paper or thin plastic sheets, between stacked items to prevent damage during transportation or storage. This method enhances stability and reduces friction, minimizing the risk of scratches, dents, or shifting of products. You can improve the safety and integrity of fragile goods by using interleaving in your packaging process.

Key Differences Between Slip Sheets and Interleaving

Slip sheets are thin, flat sheets typically made of cardboard or plastic used as a cost-effective alternative to pallets for load stability and efficient storage. Interleaving involves placing sheets of paper, plastic, or other material between layers of products to prevent damage and reduce friction during handling and transport. Your choice depends on whether you prioritize space-saving slip sheets or protective interleaving for fragile or coated goods.

Material Types and Compatibility

Slip sheets are typically made from materials such as corrugated fiberboard, plastic, or dense paperboard, offering excellent compatibility with automated forklift systems due to their lightweight and durable nature. Interleaving materials often consist of tissue paper, foam, or polyethylene film designed to prevent surface damage and improve stacking stability for delicate or high-value products. Your choice between slip sheets and interleaving should consider the type of products being handled and the required protection level for optimal material compatibility.

Advantages of Slip Sheets

Slip sheets offer significant advantages over interleaving by reducing material costs and minimizing waste due to their thinner profile and lightweight design. They improve load stability and handling efficiency, allowing for quicker palletizing and better use of storage space in warehouses or during transport. You can also benefit from enhanced automation compatibility, as slip sheets are easily integrated with mechanical handling equipment, reducing labor costs and increasing overall productivity.

Benefits of Interleaving Solutions

Interleaving solutions enhance product protection by preventing surface damage and reducing contamination between stacked items. They improve load stability during transportation and handling, minimizing product shift and damage. This method also allows for easier handling and increases efficiency in packaging and storage processes.

Applications in Various Industries

Slip sheets are widely used in industries such as food, pharmaceuticals, and electronics for efficient palletizing and reducing shipping costs, while interleaving is commonly applied in packaging and manufacturing sectors to protect delicate surfaces and prevent product damage. Your choice between slip sheets and interleaving depends on the specific handling requirements, with slip sheets offering space-saving benefits and interleaving providing enhanced surface protection. Both methods improve operational efficiency by optimizing storage and transportation across diverse industrial applications.

Cost Considerations and Operational Efficiency

Slip sheets reduce packaging costs by eliminating the need for bulky pallets, making them a cost-effective option for companies looking to optimize shipping expenses. Interleaving provides enhanced product protection and stability during transport but may increase material costs and handling time due to the added layers. Balancing slip sheets' lower cost with interleaving's potential for fewer damages, your operational efficiency depends on selecting the solution that best fits your product type and logistics requirements.

Choosing the Right Solution for Your Supply Chain

Slip sheets offer a lightweight, cost-effective alternative to traditional pallets, enhancing load stability and reducing shipping expenses. Interleaving provides added protection by placing sheets between layers of products, preventing damage during handling and transit. Evaluating your supply chain's packaging needs and material handling equipment will help you determine whether slip sheets or interleaving best optimize efficiency and product safety.

slip sheets vs interleaving Infographic

libmatt.com

libmatt.com