Kiss cut refers to a process where the top layer of material is cut without penetrating the backing, allowing easy peeling of stickers or labels, while die cut involves cutting all the way through the material to create custom shapes. Your choice depends on whether you need easy removal of stickers (kiss cut) or distinct, standalone shapes (die cut) for your project.

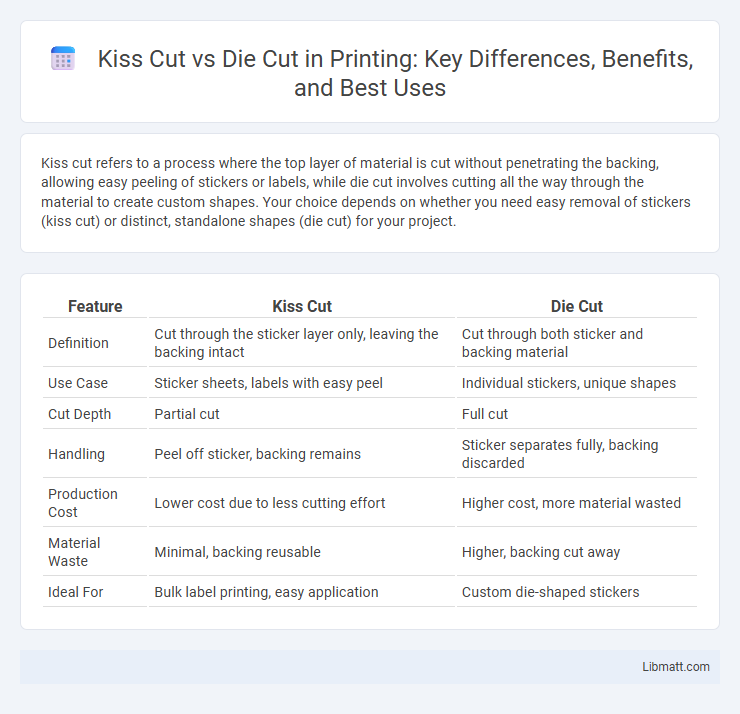

Table of Comparison

| Feature | Kiss Cut | Die Cut |

|---|---|---|

| Definition | Cut through the sticker layer only, leaving the backing intact | Cut through both sticker and backing material |

| Use Case | Sticker sheets, labels with easy peel | Individual stickers, unique shapes |

| Cut Depth | Partial cut | Full cut |

| Handling | Peel off sticker, backing remains | Sticker separates fully, backing discarded |

| Production Cost | Lower cost due to less cutting effort | Higher cost, more material wasted |

| Material Waste | Minimal, backing reusable | Higher, backing cut away |

| Ideal For | Bulk label printing, easy application | Custom die-shaped stickers |

Introduction to Kiss Cut vs Die Cut

Kiss cut and die cut are two popular cutting techniques used in sticker and label production, each serving different purposes. Kiss cut cuts through the sticker's vinyl layer without penetrating the backing paper, allowing easy peeling and preserving the integrity of the liner. Die cut cuts completely through both the vinyl and backing paper, creating standalone shapes that require no additional trimming.

Definition of Kiss Cut Stickers

Kiss cut stickers feature a cut through the vinyl layer without cutting the backing paper, allowing easy peeling and maintaining sticker integrity. This cutting technique is ideal for sticker sheets with multiple designs, enabling you to remove individual stickers while leaving the rest intact. Your sticker projects benefit from kiss cut precision, making application and storage more convenient compared to die cut stickers, which are cut entirely through the backing.

Definition of Die Cut Stickers

Die cut stickers are precisely cut to the exact shape of the design, removing all excess material around the edges for a clean, custom look. This cutting method is ideal for intricate shapes and detailed logos, giving your stickers a professional and polished appearance. Unlike kiss cut stickers, die cut stickers separate completely from the backing, making them easy to peel and apply.

Key Differences Between Kiss Cut and Die Cut

Kiss cut and die cut differ primarily in how the cutting process affects the backing material; kiss cut cuts only through the sticker layer while leaving the backing intact, making it easier to peel off. Die cut goes through both the sticker and the backing material, resulting in individual shapes and separate pieces. Kiss cuts are ideal for sticker sheets with multiple designs on one sheet, whereas die cuts provide a custom shape for each individual sticker.

Advantages of Kiss Cut Stickers

Kiss cut stickers offer the advantage of easy peeling without damaging the backing paper, ensuring precise cuts around the design while maintaining the shape's integrity. This method allows for multiple stickers to be cut on a single sheet, enabling efficient batch production and reduced material waste. The protective backing also facilitates sticker storage and application, making kiss cut stickers ideal for collectors and promotional use.

Advantages of Die Cut Stickers

Die cut stickers offer precise, custom shapes that follow the exact outline of your design, enhancing visual appeal and professionalism. They provide a cleaner finish and stronger adhesive performance, making them ideal for branding and promotional purposes. Your stickers will stand out with high durability and versatility, suitable for various surfaces and long-term use.

Common Uses for Kiss Cut vs Die Cut

Kiss cut labels are frequently used for stickers and decals that require easy peeling without detaching the backing, making them ideal for promotional items, retail packaging, and product labeling. Die cut processes are commonly applied to create custom shapes with complete cuts through materials such as paper, vinyl, or cardstock, perfect for intricate designs, packaging, and custom stickers. You can choose kiss cut for convenience in application, while die cut suits projects demanding detailed shapes and durability.

Cost Comparison: Kiss Cut vs Die Cut

Kiss cut stickers typically cost less than die cut stickers because the backing isn't fully cut through, reducing production time and material waste. Die cut stickers require precise, complete cuts around the sticker shape, which increases manufacturing complexity and expenses. Your choice between kiss cut and die cut will impact the overall budget depending on the quantity and intricacy of the design.

Tips for Choosing the Right Cut Type

Choosing between kiss cut and die cut depends on the sticker application and desired finish; kiss cut maintains the backing intact for easy peeling, ideal for sticker sheets, while die cut cuts through both sticker and backing, perfect for individual shapes. Evaluate the complexity of the design and production volume, as kiss cut is more cost-effective for multiple stickers on a single sheet. Consider durability and user experience, selecting die cut for high-end, standalone stickers requiring precise edges and kiss cut for convenience in bulk distribution.

Conclusion: Kiss Cut or Die Cut?

Kiss cut and die cut labels serve different purposes based on your project needs; kiss cuts keep the label intact on its backing for easy peeling, ideal for sticker sheets or multi-label designs, while die cuts cut through the entire material, offering fully separated shapes for bold, standalone decals. Your choice depends on whether you want a convenient peel-away design or a distinct, individual cutout that stands alone. Selecting the appropriate cut type enhances both the functionality and visual impact of your printed materials.

kiss cut vs die cut Infographic

libmatt.com

libmatt.com