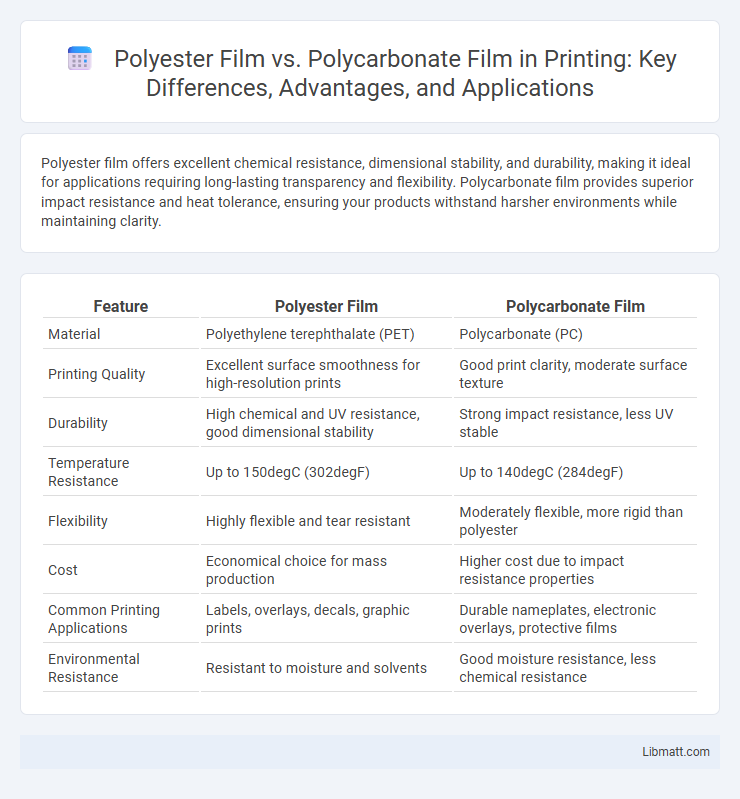

Polyester film offers excellent chemical resistance, dimensional stability, and durability, making it ideal for applications requiring long-lasting transparency and flexibility. Polycarbonate film provides superior impact resistance and heat tolerance, ensuring your products withstand harsher environments while maintaining clarity.

Table of Comparison

| Feature | Polyester Film | Polycarbonate Film |

|---|---|---|

| Material | Polyethylene terephthalate (PET) | Polycarbonate (PC) |

| Printing Quality | Excellent surface smoothness for high-resolution prints | Good print clarity, moderate surface texture |

| Durability | High chemical and UV resistance, good dimensional stability | Strong impact resistance, less UV stable |

| Temperature Resistance | Up to 150degC (302degF) | Up to 140degC (284degF) |

| Flexibility | Highly flexible and tear resistant | Moderately flexible, more rigid than polyester |

| Cost | Economical choice for mass production | Higher cost due to impact resistance properties |

| Common Printing Applications | Labels, overlays, decals, graphic prints | Durable nameplates, electronic overlays, protective films |

| Environmental Resistance | Resistant to moisture and solvents | Good moisture resistance, less chemical resistance |

Introduction to Polyester and Polycarbonate Films

Polyester film, known for its exceptional tensile strength and chemical resistance, is widely used in packaging, electronics, and insulation due to its stability and clarity. Polycarbonate film offers superior impact resistance and high heat tolerance, making it ideal for applications requiring durability and optical clarity such as in protective screens and automotive components. Both films exhibit unique properties tailored for specialized industrial and consumer applications, with polyester excelling in flexibility and polycarbonate in toughness.

Material Composition and Properties

Polyester film, primarily composed of polyethylene terephthalate (PET), offers high tensile strength, excellent dimensional stability, and superior resistance to moisture, chemicals, and UV radiation, making it ideal for packaging and insulation applications. Polycarbonate film, derived from bisphenol A and phosgene, provides exceptional impact resistance, higher temperature tolerance up to 150degC, and superior optical clarity, commonly used in protective screens and electronics. While polyester excels in chemical and environmental durability, polycarbonate is favored for applications demanding toughness and thermal endurance.

Mechanical Strength and Durability

Polycarbonate film offers superior mechanical strength with high impact resistance and excellent dimensional stability under stress, making it ideal for applications requiring toughness and durability. Polyester film, while less impact-resistant than polycarbonate, provides good tensile strength and flexibility, along with better resistance to moisture and UV exposure. Both materials deliver durable performance, but polycarbonate film excels in high-stress environments where enhanced durability and resistance to cracking are critical.

Optical Clarity and Transparency

Polycarbonate film exhibits superior optical clarity and transparency compared to polyester film, offering higher light transmittance and reduced haze levels, essential for applications requiring precise visual performance. Polyester film, while durable and cost-effective, typically has moderate transparency and slightly higher haze, which can affect image sharpness and color accuracy. These optical properties make polycarbonate preferable for high-definition displays and optical lenses, whereas polyester is commonly used in packaging and lower-priority visual applications.

Chemical and Thermal Resistance

Polyester film exhibits excellent chemical resistance against acids, alkalis, and solvents, maintaining stability up to temperatures around 150degC, making it suitable for harsh chemical environments. Polycarbonate film offers superior thermal resistance, withstanding temperatures up to 140degC while providing better impact resistance and dimensional stability under thermal stress. Both films resist moisture absorption, but polyester outperforms in long-term chemical exposure, whereas polycarbonate excels in applications requiring toughness and heat endurance.

Flexibility and Formability

Polyester film offers exceptional flexibility, allowing it to bend and conform easily to curved surfaces without cracking, making it ideal for applications requiring frequent deformation. Polycarbonate film, while slightly less flexible, provides superior impact resistance and formability, enabling precise molding into complex shapes without losing structural integrity. Your choice depends on whether you prioritize ease of bending (polyester) or enhanced toughness and detailed forming (polycarbonate).

Printing and Surface Treatments

Polyester film offers excellent surface smoothness and chemical resistance, making it ideal for high-quality printing and various surface treatments like corona or plasma to enhance ink adhesion. Polycarbonate film provides superior durability and heat resistance but may require specialized surface treatments to improve ink receptivity for detailed prints. Your choice depends on the specific printing technique and durability needs, with polyester favored for vibrant graphics and polycarbonate preferred in applications demanding robustness and thermal stability.

Applications in Various Industries

Polyester film offers excellent chemical resistance and electrical insulation, making it ideal for packaging, electronics, and magnetic media industries. Polycarbonate film, known for its high impact resistance and optical clarity, is preferred in automotive, medical devices, and optical applications. Your choice depends on the specific performance requirements, such as durability or transparency, demanded by your industry.

Cost Comparison and Availability

Polyester film is generally more cost-effective than polycarbonate film due to its widespread manufacturing and lower raw material expenses. Polycarbonate film, while offering superior impact resistance and clarity, tends to be pricier and less readily available, often requiring specialized suppliers. Your choice between these films should consider the budget constraints and the specific availability within your supply chain.

Sustainability and Environmental Impact

Polyester film offers high recyclability and a lower carbon footprint due to its energy-efficient manufacturing processes, making it a more sustainable choice compared to polycarbonate film. Polycarbonate film, while durable and impact-resistant, involves more complex production that generates higher greenhouse gas emissions and poses greater challenges for recycling. Choosing polyester film reduces environmental impact by enabling easier end-of-life processing and supporting circular economy initiatives.

Polyester Film vs Polycarbonate Film Infographic

libmatt.com

libmatt.com