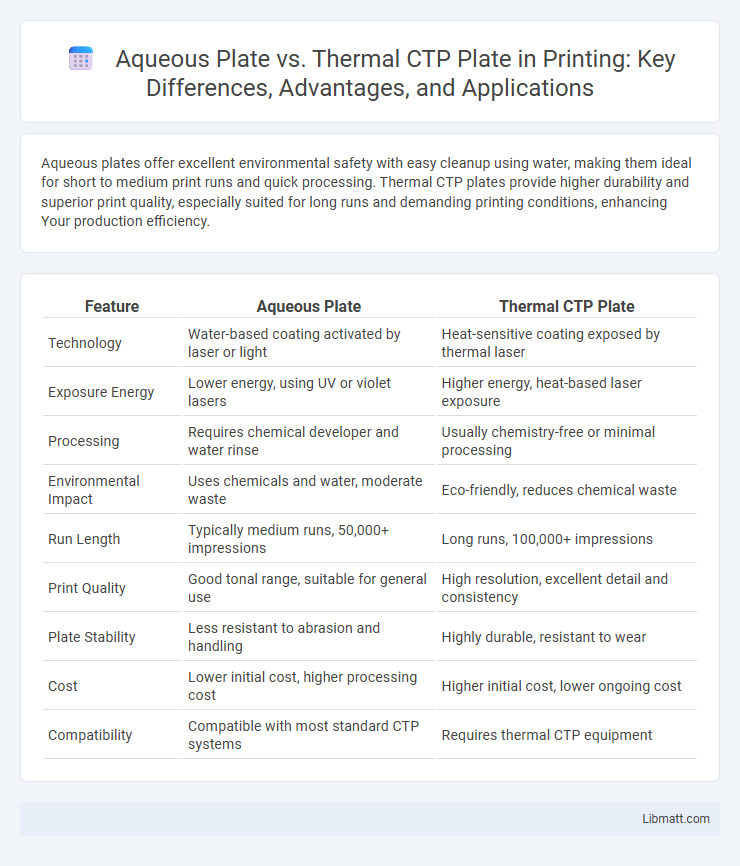

Aqueous plates offer excellent environmental safety with easy cleanup using water, making them ideal for short to medium print runs and quick processing. Thermal CTP plates provide higher durability and superior print quality, especially suited for long runs and demanding printing conditions, enhancing Your production efficiency.

Table of Comparison

| Feature | Aqueous Plate | Thermal CTP Plate |

|---|---|---|

| Technology | Water-based coating activated by laser or light | Heat-sensitive coating exposed by thermal laser |

| Exposure Energy | Lower energy, using UV or violet lasers | Higher energy, heat-based laser exposure |

| Processing | Requires chemical developer and water rinse | Usually chemistry-free or minimal processing |

| Environmental Impact | Uses chemicals and water, moderate waste | Eco-friendly, reduces chemical waste |

| Run Length | Typically medium runs, 50,000+ impressions | Long runs, 100,000+ impressions |

| Print Quality | Good tonal range, suitable for general use | High resolution, excellent detail and consistency |

| Plate Stability | Less resistant to abrasion and handling | Highly durable, resistant to wear |

| Cost | Lower initial cost, higher processing cost | Higher initial cost, lower ongoing cost |

| Compatibility | Compatible with most standard CTP systems | Requires thermal CTP equipment |

Introduction to CTP Plate Technologies

Computer-to-Plate (CTP) technologies include aqueous and thermal plates, each utilizing distinct imaging processes for printing optimization. Aqueous plates employ water-soluble coatings and conventional lasers, offering cost-effective solutions with moderate durability suitable for shorter print runs. Thermal CTP plates utilize infrared laser technology to create highly durable, chemical-free plates ideal for high-volume production and superior print quality.

What Are Aqueous CTP Plates?

Aqueous CTP plates are computer-to-plate printing plates designed to be processed with water-based developers instead of traditional chemicals, making them more environmentally friendly and easier to handle. These plates maintain high image quality and resolution while reducing the need for hazardous solvents, which benefits both the printing workflow and workplace safety. Your choice of aqueous CTP plates can enhance sustainability without compromising print performance or durability.

What Are Thermal CTP Plates?

Thermal CTP plates use heat-sensitive technology to create images directly on the plate without the need for chemical processing, enhancing print quality and durability. Unlike aqueous plates that require water-based solutions and post-exposure processing, thermal plates employ infrared lasers to harden the coating, resulting in higher resolution and resistance to abrasion. These plates are favored in commercial printing for their eco-friendly workflow, faster turnaround, and superior image stability.

Imaging Mechanism: Aqueous vs Thermal Plates

Aqueous plates use water-based chemistry for imaging, relying on hydrophilic and hydrophobic interactions to create the image on the plate surface. Thermal CTP plates utilize a laser to induce a chemical change in a heat-sensitive coating, enabling higher durability and precise image reproduction without the need for wet processing. Understanding your printing needs helps determine whether the quick processing of aqueous plates or the robust, solvent-free imaging of thermal plates is more suitable.

Workflow Differences in Plate Processing

Aqueous plates require a water-based processing step that is simpler and faster, allowing immediate handling after exposure with minimal chemical use. Thermal CTP plates involve a heat-based development process that extends processing time and demands precise temperature control for optimal image quality. The thermal method typically integrates automated processors, enhancing consistency but increasing workflow complexity compared to the straightforward aqueous workflow.

Print Quality Comparison

Aqueous plates provide consistent print quality with moderate durability, making them suitable for short to medium print runs, whereas thermal CTP plates deliver superior resolution and higher durability ideal for long runs and intricate designs. Thermal plates exhibit enhanced dot reproduction and better tonal range, resulting in sharper images and more precise color registration. Your choice depends on the required print clarity and volume, with thermal plates generally offering the highest quality outcomes for professional printing needs.

Environmental Impact and Sustainability

Aqueous CTP plates significantly reduce environmental impact by eliminating the need for harmful chemicals and solvents used in thermal CTP plate processing, resulting in safer waste disposal and lower VOC emissions. They require less energy consumption since they use water-based solutions instead of thermal energy for development, contributing to greater sustainability in print production. The biodegradability and reduced chemical toxicity of aqueous plates support eco-friendly printing practices, aligning with industry standards for environmental responsibility.

Cost Efficiency: Aqueous vs Thermal CTP

Aqueous CTP plates offer lower upfront costs due to simpler processing requirements and compatibility with standard plate setters, making them ideal for short-run print jobs and budget-conscious operations. Thermal CTP plates, while involving higher initial investment in equipment and chemistry, provide greater longevity and reduced waste, translating to cost savings in long-term, high-volume printing environments. Choosing between aqueous and thermal CTP plates depends on balancing immediate expenses against durability and productivity benefits to optimize overall cost efficiency.

Maintenance and Durability

Aqueous plates require minimal maintenance due to their water-based processing, reducing chemical handling and disposal costs, and they maintain consistent performance with less frequent cleaning. Thermal CTP plates exhibit higher durability and extended press life thanks to their heat-resistant coatings, which withstand longer runs and harsh press conditions. The choice between the two depends on balancing the lower upkeep of aqueous plates against the superior longevity and robustness of thermal plates.

Choosing the Right CTP Plate for Your Press

Selecting the right CTP plate for your press hinges on understanding the distinct advantages of aqueous and thermal plates. Aqueous plates offer simpler processing with water-based chemistry, ideal for shorter print runs and environmentally friendly operations, while thermal plates deliver higher durability, faster imaging, and superior resistance to press environments, suitable for high-volume and high-quality print production. Assessing your press workload, run length, and environmental considerations ensures optimal plate performance and cost-efficiency.

aqueous plate vs thermal CTP plate Infographic

libmatt.com

libmatt.com