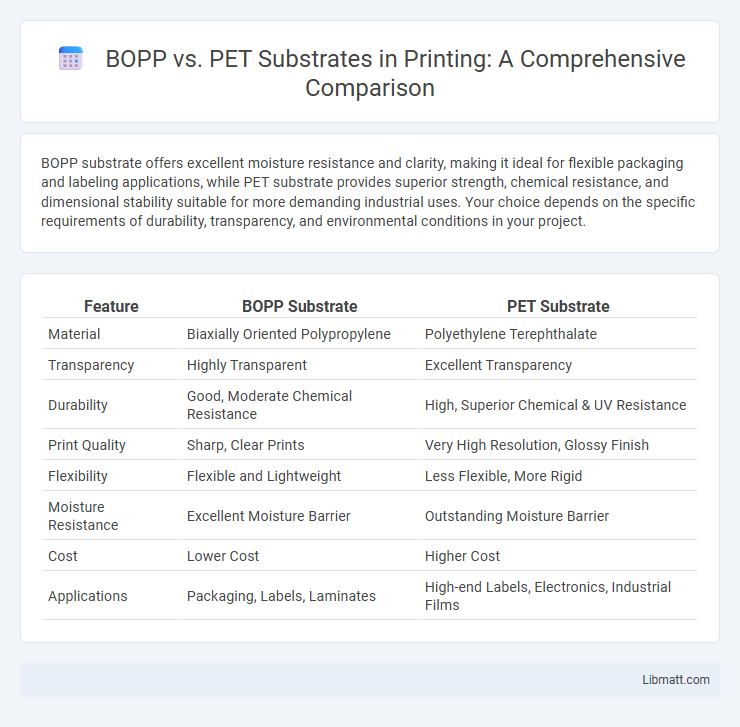

BOPP substrate offers excellent moisture resistance and clarity, making it ideal for flexible packaging and labeling applications, while PET substrate provides superior strength, chemical resistance, and dimensional stability suitable for more demanding industrial uses. Your choice depends on the specific requirements of durability, transparency, and environmental conditions in your project.

Table of Comparison

| Feature | BOPP Substrate | PET Substrate |

|---|---|---|

| Material | Biaxially Oriented Polypropylene | Polyethylene Terephthalate |

| Transparency | Highly Transparent | Excellent Transparency |

| Durability | Good, Moderate Chemical Resistance | High, Superior Chemical & UV Resistance |

| Print Quality | Sharp, Clear Prints | Very High Resolution, Glossy Finish |

| Flexibility | Flexible and Lightweight | Less Flexible, More Rigid |

| Moisture Resistance | Excellent Moisture Barrier | Outstanding Moisture Barrier |

| Cost | Lower Cost | Higher Cost |

| Applications | Packaging, Labels, Laminates | High-end Labels, Electronics, Industrial Films |

Introduction to BOPP and PET Substrates

BOPP (Biaxially Oriented Polypropylene) and PET (Polyethylene Terephthalate) substrates are widely utilized in flexible packaging and labeling industries due to their distinct physical and chemical properties. BOPP offers excellent moisture resistance, clarity, and cost-effectiveness, making it ideal for food packaging applications, while PET provides superior mechanical strength, temperature resistance, and dimensional stability suited for high-performance labels and laminates. The choice between BOPP and PET depends on application-specific requirements such as barrier properties, printability, and environmental considerations.

Chemical Structure and Composition

BOPP (Biaxially Oriented Polypropylene) substrate consists of isotactic polypropylene chains arranged through biaxial orientation, enhancing tensile strength and chemical resistance. PET (Polyethylene Terephthalate) substrate is composed of repeating ester units derived from terephthalic acid and ethylene glycol, providing superior thermal stability and dimensional integrity. Understanding the distinct polymer compositions of BOPP and PET can guide your choice for applications requiring specific mechanical and chemical properties.

Key Physical Properties Comparison

BOPP substrate offers superior tensile strength and high moisture resistance, making it ideal for packaging that requires durability and barrier protection. PET substrate excels in temperature tolerance and dimensional stability, with higher heat resistance and better chemical resistance compared to BOPP. Both substrates provide excellent clarity and printability, but PET generally supports more precise color reproduction due to its smoother surface.

Optical Clarity and Appearance

BOPP substrate offers high optical clarity with excellent gloss and transparency, making it ideal for vibrant label printing and eye-catching packaging. PET substrate provides superior clarity with exceptional resistance to heat and chemicals, ensuring a crisp and durable appearance in demanding environments. Your choice between BOPP and PET will impact the visual appeal and performance of your printed materials under various lighting conditions.

Barrier Properties: Moisture and Gas

BOPP substrate offers excellent moisture barrier properties, making it ideal for packaging products sensitive to humidity. PET substrate provides superior gas barrier performance, effectively protecting contents from oxygen and preserving freshness. Your choice between BOPP and PET should depend on whether moisture or gas protection is more critical for your application.

Printability and Surface Treatment

BOPP substrates offer excellent printability due to their high surface energy after corona treatment, allowing for superior ink adhesion and vibrant color reproduction, especially in flexographic and gravure printing. PET substrates inherently have a smoother surface and lower surface energy, often requiring plasma or corona surface treatment to enhance printability and promote ink adhesion. Surface treatments on both BOPP and PET significantly improve bonding performance, but PET's chemical resistance and thermal stability make it preferable for applications demanding high durability and dimensional stability in printed labels.

Mechanical Strength and Durability

BOPP substrate offers excellent tensile strength and flexibility, making it highly resistant to tearing and punctures in packaging applications. PET substrate surpasses BOPP in mechanical strength with superior impact resistance and dimensional stability, ensuring enhanced durability under extreme conditions. Your choice depends on whether you prioritize cost-effective flexibility (BOPP) or robust, long-lasting performance (PET) for your specific needs.

Applications in Packaging Industries

BOPP substrate is widely utilized in food packaging due to its excellent moisture resistance, high clarity, and cost-effectiveness, making it ideal for snack wrappers and labels. PET substrate offers superior mechanical strength, dimensional stability, and chemical resistance, favored for high-end packaging such as beverage labels and shrink sleeves. Your packaging choice depends on specific requirements like durability, print quality, and environmental conditions, with BOPP excelling in budget-friendly applications and PET preferred for premium product protection.

Environmental Impact and Recyclability

BOPP substrate offers lower environmental impact due to its higher recyclability and lower energy consumption during production compared to PET substrate, which is derived from petroleum and requires more energy-intensive processes. PET substrate, while providing superior durability and chemical resistance, poses recycling challenges because its strong polymer chains make it less biodegradable and more difficult to process in standard recycling streams. Choosing BOPP promotes more sustainable packaging solutions by reducing carbon footprint and enhancing circular economy potential through easier material recovery and reuse.

Cost Analysis and Market Trends

BOPP substrate offers a cost advantage over PET substrate due to lower raw material prices and manufacturing expenses, making it a preferred choice for budget-sensitive packaging applications. PET substrate, while more expensive, provides superior durability, clarity, and barrier properties, driving demand in high-performance and premium packaging markets. Your choice between BOPP and PET should consider current market trends showing a gradual shift towards sustainable PET alternatives as environmental regulations and consumer preferences evolve.

BOPP vs PET Substrate Infographic

libmatt.com

libmatt.com