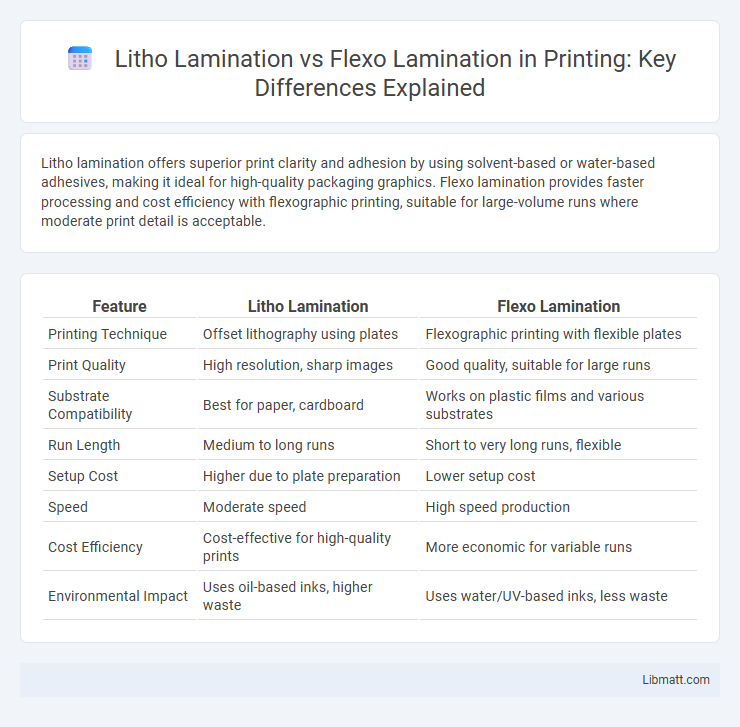

Litho lamination offers superior print clarity and adhesion by using solvent-based or water-based adhesives, making it ideal for high-quality packaging graphics. Flexo lamination provides faster processing and cost efficiency with flexographic printing, suitable for large-volume runs where moderate print detail is acceptable.

Table of Comparison

| Feature | Litho Lamination | Flexo Lamination |

|---|---|---|

| Printing Technique | Offset lithography using plates | Flexographic printing with flexible plates |

| Print Quality | High resolution, sharp images | Good quality, suitable for large runs |

| Substrate Compatibility | Best for paper, cardboard | Works on plastic films and various substrates |

| Run Length | Medium to long runs | Short to very long runs, flexible |

| Setup Cost | Higher due to plate preparation | Lower setup cost |

| Speed | Moderate speed | High speed production |

| Cost Efficiency | Cost-effective for high-quality prints | More economic for variable runs |

| Environmental Impact | Uses oil-based inks, higher waste | Uses water/UV-based inks, less waste |

Introduction to Litho Lamination and Flexo Lamination

Litho lamination uses offset lithography to transfer high-quality, detailed images onto packaging materials, ideal for premium visual appeal. Flexo lamination employs flexible relief plates for fast, cost-effective printing on a variety of substrates, suitable for large-scale production runs. Both methods enhance packaging durability and aesthetics, with litho offering superior image precision and flexo providing efficient, adaptable printing solutions.

Key Differences Between Litho and Flexo Lamination

Litho lamination involves bonding pre-printed substrates with high-quality, detailed images ideal for packaging that demands sharp graphics, while flexo lamination uses flexible printing plates suited for continuous, high-speed production processes. Flexo lamination excels in cost-effectiveness for large runs thanks to simpler plate making and faster setup times, whereas litho lamination provides superior print clarity and color accuracy. Your choice depends on balancing image quality needs with production efficiency and budget constraints.

Process Overview: How Litho Lamination Works

Litho lamination involves applying a printed image from a lithographic printing plate onto a substrate using heat and pressure, creating a high-quality, durable finish. This process uses offset printing techniques to transfer ink onto a carrier before being laminated onto materials like paper, film, or foil. You benefit from litho lamination's superior image clarity and color fidelity, making it ideal for premium packaging applications.

Process Overview: How Flexo Lamination Works

Flexo lamination uses flexible relief plates to transfer ink onto a substrate, followed by adhesive application and heat or pressure to bond films. The process allows high-speed production with precise control of ink thickness and film adhesion, making it ideal for flexible packaging. Compared to litho lamination, flexo lamination offers faster setup times and better suitability for long runs with varying substrate materials.

Print Quality Comparison: Litho vs Flexo Lamination

Litho lamination delivers superior print quality with sharper images and finer details due to its high-resolution lithographic printing process, ideal for premium packaging. Flexo lamination offers faster production speeds but typically produces lower resolution prints, making it suitable for large-volume runs where speed outweighs intricate detail. Your choice between litho and flexo lamination should weigh the trade-off between print clarity and cost-efficiency based on your project's quality requirements.

Cost Efficiency: Litho Lamination vs Flexo Lamination

Litho lamination generally incurs higher initial setup costs due to detailed image quality and complex plate preparation, making it less cost-efficient for short runs. Flexo lamination offers lower setup expenses and faster turnaround times, enhancing cost efficiency, especially in large-volume production. Businesses aiming for budget-friendly solutions with consistent quality often prefer flexo lamination for optimized cost management.

Suitable Applications for Litho Lamination

Litho lamination excels in high-quality graphics and packaging requiring sharp, vibrant images, such as luxury product boxes, labels, and specialty printing. Its precise registration and superior gloss make it ideal for premium branding and marketing materials where visual impact is crucial. You can rely on litho lamination for applications demanding exceptional print definition and durability.

Suitable Applications for Flexo Lamination

Flexo lamination is ideal for packaging materials requiring fast turnaround and cost-effective short to medium runs, such as food wrappers, labels, and flexible packaging films. Its compatibility with a wide range of substrates, including BOPP, PET, and paper, allows you to create durable, high-quality laminated products with excellent moisture resistance. Flexo lamination excels in applications that demand vibrant print clarity and strong adhesion in high-speed production environments.

Sustainability and Environmental Impact

Litho lamination uses solvent-based adhesives that release higher VOC emissions, contributing to environmental pollution and posing disposal challenges, whereas flexo lamination often employs water-based or UV-curable adhesives, reducing harmful emissions and enhancing recyclability. Your choice between litho and flexo lamination impacts carbon footprint, with flexo lamination offering a more sustainable option due to lower energy consumption and less waste. Both processes require careful consideration of material compatibility, but flexo lamination aligns better with eco-friendly packaging initiatives and regulatory compliance.

Choosing the Right Lamination Method for Your Packaging

Selecting between litho lamination and flexo lamination depends on factors such as print quality, production speed, and budget constraints. Litho lamination offers high-definition image reproduction ideal for premium packaging with intricate designs, while flexo lamination provides faster processing and cost-effective solutions for large-volume runs. Understanding your packaging requirements and desired finish will help ensure you choose the optimal lamination method to enhance your product's appeal and durability.

litho lamination vs flexo lamination Infographic

libmatt.com

libmatt.com