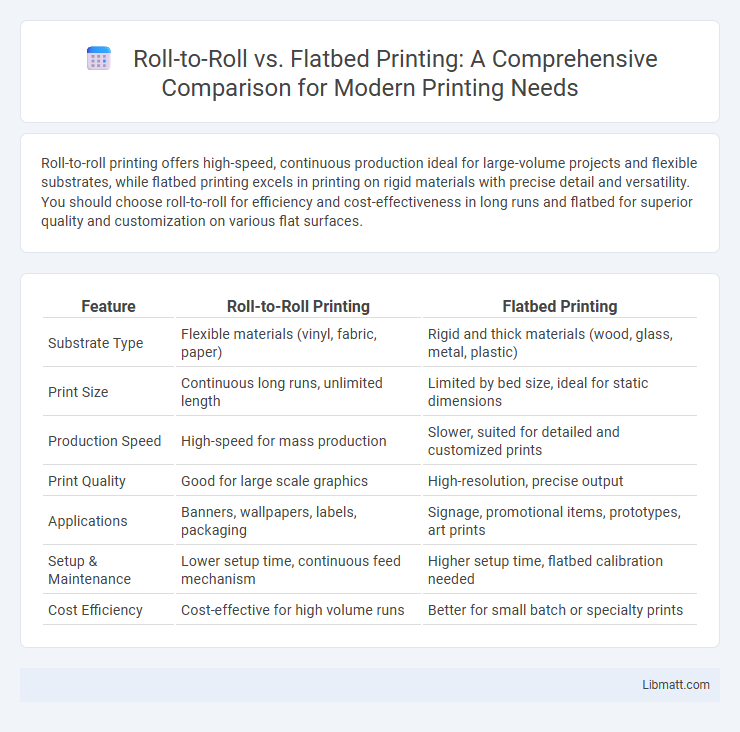

Roll-to-roll printing offers high-speed, continuous production ideal for large-volume projects and flexible substrates, while flatbed printing excels in printing on rigid materials with precise detail and versatility. You should choose roll-to-roll for efficiency and cost-effectiveness in long runs and flatbed for superior quality and customization on various flat surfaces.

Table of Comparison

| Feature | Roll-to-Roll Printing | Flatbed Printing |

|---|---|---|

| Substrate Type | Flexible materials (vinyl, fabric, paper) | Rigid and thick materials (wood, glass, metal, plastic) |

| Print Size | Continuous long runs, unlimited length | Limited by bed size, ideal for static dimensions |

| Production Speed | High-speed for mass production | Slower, suited for detailed and customized prints |

| Print Quality | Good for large scale graphics | High-resolution, precise output |

| Applications | Banners, wallpapers, labels, packaging | Signage, promotional items, prototypes, art prints |

| Setup & Maintenance | Lower setup time, continuous feed mechanism | Higher setup time, flatbed calibration needed |

| Cost Efficiency | Cost-effective for high volume runs | Better for small batch or specialty prints |

Introduction to Roll-to-Roll and Flatbed Printing

Roll-to-roll printing involves continuous printing on flexible materials like vinyl or fabric, ideal for high-volume production and long runs. Flatbed printing uses a stationary flat surface to print directly onto rigid or thick substrates such as glass, wood, or metal, offering precision and versatility for diverse applications. Both methods cater to different industrial needs, with roll-to-roll excelling in speed and material handling, while flatbed excels in customization and substrate variety.

How Roll-to-Roll Printing Works

Roll-to-roll printing involves continuously feeding a flexible substrate, such as vinyl or fabric, from one roll to another through a series of printing stations. This method uses rollers to apply inks or coatings efficiently, allowing high-speed production of large volumes with consistent quality. Your choice in printing depends on the need for speed and flexibility, as roll-to-roll excels in continuous, large-scale applications compared to flatbed printing.

How Flatbed Printing Works

Flatbed printing uses a stationary, flat surface where rigid or flexible materials are placed for precise ink application via print heads that move across the substrate. This method allows for high-resolution, detailed prints on diverse materials such as wood, metal, and glass without the need for continuous rolls. The process excels in producing short runs, prototypes, and customized products with consistent color accuracy and sharpness.

Key Differences Between Roll-to-Roll and Flatbed Printing

Roll-to-roll printing excels in high-volume, continuous production by using flexible materials fed from rolls, making it ideal for banners and labels. Flatbed printing handles rigid substrates with precision, suitable for signage and customized prints on materials like wood or metal. Your choice depends on substrate type, production speed, and application requirements, with roll-to-roll offering efficiency for flexible media and flatbed providing versatility for solid surfaces.

Material Compatibility and Versatility

Roll-to-roll printing excels in processing flexible materials such as vinyl, fabric, and thin films, making it ideal for continuous, high-volume production runs. Flatbed printing supports a wider range of rigid and irregular substrates including wood, glass, and metal, offering superior versatility for custom or short-run applications. Material compatibility drives the choice between roll-to-roll for flexible media and flatbed printing for diverse or thick materials.

Print Speed and Production Efficiency

Roll-to-roll printing offers significantly higher print speeds and enhanced production efficiency as it continuously processes flexible materials on rolls, enabling uninterrupted runs and faster turnaround times. Flatbed printing, while ideal for rigid substrates and detailed prints, operates at slower speeds due to the stationary nature of the media and the necessity for step-and-repeat movements. Manufacturers prioritize roll-to-roll systems for large volume outputs requiring rapid production, whereas flatbed printers are preferred for precision work and shorter runs.

Print Quality and Resolution Comparison

Roll-to-roll printing offers high-speed production with consistent print quality, but its resolution typically maxes out around 720 to 1440 dpi, making it ideal for large-scale banners and flexible media. Flatbed printing delivers superior print quality with resolutions reaching 1200 dpi or higher, enabling precise detail and sharp images on rigid substrates. The choice between the two depends on the required print resolution and substrate type, with flatbed excelling in detail and roll-to-roll favoring volume and flexibility.

Cost Considerations: Investment and Operation

Roll-to-roll printing typically involves higher initial investment due to continuous feed systems but offers lower operational costs through faster production speeds and reduced material waste. Flatbed printing requires less upfront capital, making it suitable for smaller batches, yet incurs higher per-unit costs because of slower processing and increased labor. Choosing the right technology depends on your production volume and budget priorities, balancing startup expenditure against ongoing efficiency.

Industry Applications and Best Use Cases

Roll-to-roll printing excels in high-volume production for flexible materials like labels, packaging, and textiles, making it ideal for industries requiring continuous and fast printing processes. Flatbed printing suits rigid substrates such as glass, wood, and metal, commonly used in signage, promotional items, and industrial parts where precision and detailed imaging are crucial. Your choice depends on the material type and production scale, with roll-to-roll favored for efficiency in large runs and flatbed for versatility and high-quality output on solid surfaces.

Choosing the Right Printing Technology for Your Business

Roll-to-roll printing offers high-speed production and is ideal for continuous media like banners and labels, providing efficiency for large-volume runs. Flatbed printing excels in precision and versatility, allowing you to print on rigid materials such as wood, glass, and metal, making it perfect for customized or small-batch projects. Evaluating your product type, production volume, and material compatibility will help you choose the right printing technology for your business needs.

Roll-to-roll vs flatbed printing Infographic

libmatt.com

libmatt.com