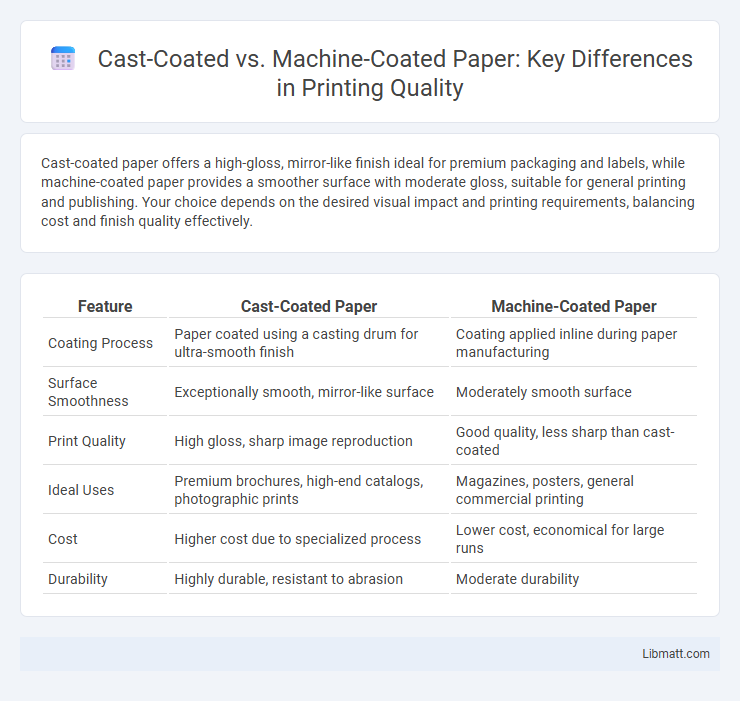

Cast-coated paper offers a high-gloss, mirror-like finish ideal for premium packaging and labels, while machine-coated paper provides a smoother surface with moderate gloss, suitable for general printing and publishing. Your choice depends on the desired visual impact and printing requirements, balancing cost and finish quality effectively.

Table of Comparison

| Feature | Cast-Coated Paper | Machine-Coated Paper |

|---|---|---|

| Coating Process | Paper coated using a casting drum for ultra-smooth finish | Coating applied inline during paper manufacturing |

| Surface Smoothness | Exceptionally smooth, mirror-like surface | Moderately smooth surface |

| Print Quality | High gloss, sharp image reproduction | Good quality, less sharp than cast-coated |

| Ideal Uses | Premium brochures, high-end catalogs, photographic prints | Magazines, posters, general commercial printing |

| Cost | Higher cost due to specialized process | Lower cost, economical for large runs |

| Durability | Highly durable, resistant to abrasion | Moderate durability |

Introduction to Cast-Coated and Machine-Coated Paper

Cast-coated paper features a high-gloss finish achieved by pressing the paper against a highly polished metal surface, resulting in excellent print quality and smoothness ideal for premium packaging and labels. Machine-coated paper, produced by applying a coating directly in the papermaking machine, offers good printability with more cost-effective production and is commonly used for magazines, catalogs, and brochures. The choice between cast-coated and machine-coated paper depends on the desired surface gloss, print detail, and budget constraints in printing projects.

What Is Cast-Coated Paper?

Cast-coated paper features a high-gloss finish achieved by pressing the paper against a highly polished, heated metal drum during manufacturing, resulting in a smooth, mirror-like surface. This finish enhances color vibrancy and sharp image reproduction, making it ideal for premium printing applications such as magazines, catalogs, and high-end packaging. Understanding the unique properties of cast-coated paper can help you select the right material for projects requiring superior gloss and clarity.

What Is Machine-Coated Paper?

Machine-coated paper features a smooth surface achieved by applying a coating directly during the manufacturing process using a specialized blade or roller. This type of paper provides excellent printability, making it ideal for high-volume commercial printing such as magazines and catalogs. You benefit from its consistent finish and cost-effectiveness compared to cast-coated paper, which undergoes an additional curing process for ultra-glossy results.

Key Differences Between Cast-Coated and Machine-Coated Paper

Cast-coated paper features a glossy, mirror-like finish achieved by casting the coating onto a heated, polished steel drum, resulting in superior surface smoothness and high-quality print clarity. Machine-coated paper, coated directly on the paper machine, typically has a more uniform but less glossy surface, suitable for everyday printing needs. The key difference lies in production techniques, surface finish, and print performance, with cast-coated paper excelling in premium visual applications and machine-coated paper favored for cost-effective, high-volume prints.

Surface Finish and Gloss: A Comparative Analysis

Cast-coated paper exhibits a high-gloss, mirror-like finish achieved through a process involving the application of coating while the paper is pressed against a highly polished metal surface, resulting in superior smoothness and reflectivity. Machine-coated paper, produced by applying coating during the paper manufacturing process, offers a more matte or semi-gloss finish with less intense shine and texture uniformity. The key difference lies in cast-coated paper providing enhanced surface gloss and a smoother finish, making it ideal for premium printing and packaging applications requiring vibrant image reproduction.

Print Quality and Color Reproduction

Cast-coated paper offers superior print quality with a smooth, glossy finish that enhances color reproduction by providing sharp, vibrant images ideal for high-end graphics. Machine-coated paper generally provides a more matte or semi-gloss surface, resulting in less vivid colors and slightly lower print sharpness. For your projects demanding bright, crisp visuals, cast-coated paper ensures more accurate color fidelity and detail.

Applications and Best Use Cases

Cast-coated paper offers a high-gloss finish ideal for premium packaging, labels, and photographic prints where vibrant color reproduction and sharp image detail are essential. Machine-coated paper, featuring a smoother surface with moderate gloss, suits applications such as magazines, catalogs, and brochures that require cost-effective printing with good ink holdout and readability. Both papers excel in different sectors of the printing industry, with cast-coated paper preferred for luxury branding and machine-coated paper favored for high-volume commercial printing tasks.

Cost Considerations and Availability

Cast-coated paper generally incurs higher production costs due to its complex manufacturing process, resulting in a premium price compared to machine-coated paper. Machine-coated paper offers more cost-effective options with quicker turnaround times, making it widely available for high-volume printing projects. Availability favors machine-coated paper as it is mass-produced and stocked in larger quantities, whereas cast-coated paper is often produced in smaller batches for specialized applications.

Environmental Impact and Sustainability

Cast-coated paper demonstrates higher recyclability due to its thinner coating layer, resulting in less chemical usage and lower environmental burden compared to machine-coated paper, which employs thicker coatings that can hinder fiber recovery during recycling. Machine-coated paper often contains higher volumes of synthetic pigments and binders, contributing to increased energy consumption and greater greenhouse gas emissions during production. Sustainable practices favor cast-coated paper for its enhanced biodegradability and compatibility with eco-friendly printing processes, reducing overall ecological footprint.

Choosing the Right Paper for Your Project

Cast-coated paper features a high-gloss finish achieved through a casting process, ideal for projects requiring sharp image reproduction and vibrant color contrast. Machine-coated paper offers a smooth surface with moderate gloss, balancing cost and quality for applications like brochures and catalogs. Selecting the right paper depends on project goals, with cast-coated paper suited for premium visuals and machine-coated paper preferred for budget-conscious, versatile prints.

Cast-Coated vs Machine-Coated Paper Infographic

libmatt.com

libmatt.com