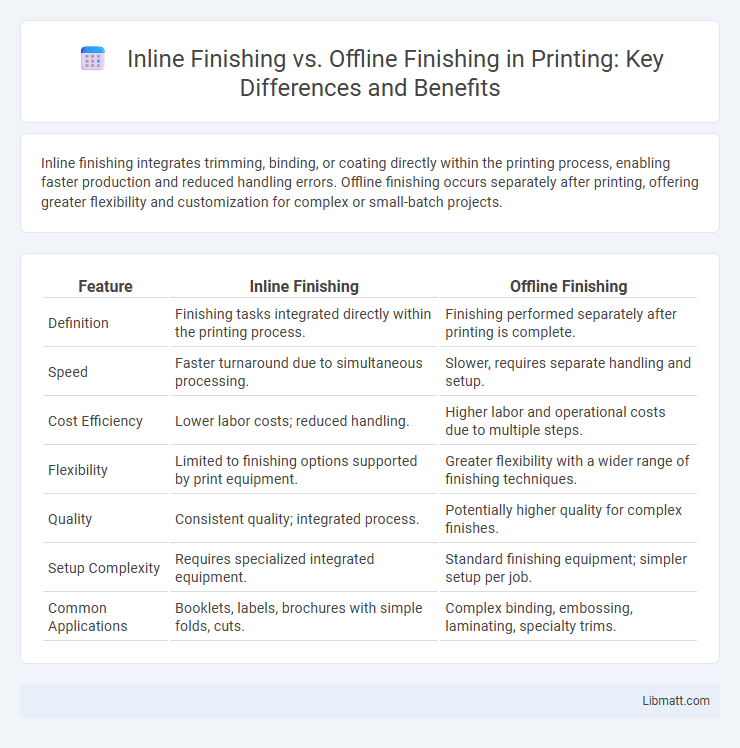

Inline finishing integrates trimming, binding, or coating directly within the printing process, enabling faster production and reduced handling errors. Offline finishing occurs separately after printing, offering greater flexibility and customization for complex or small-batch projects.

Table of Comparison

| Feature | Inline Finishing | Offline Finishing |

|---|---|---|

| Definition | Finishing tasks integrated directly within the printing process. | Finishing performed separately after printing is complete. |

| Speed | Faster turnaround due to simultaneous processing. | Slower, requires separate handling and setup. |

| Cost Efficiency | Lower labor costs; reduced handling. | Higher labor and operational costs due to multiple steps. |

| Flexibility | Limited to finishing options supported by print equipment. | Greater flexibility with a wider range of finishing techniques. |

| Quality | Consistent quality; integrated process. | Potentially higher quality for complex finishes. |

| Setup Complexity | Requires specialized integrated equipment. | Standard finishing equipment; simpler setup per job. |

| Common Applications | Booklets, labels, brochures with simple folds, cuts. | Complex binding, embossing, laminating, specialty trims. |

Understanding Inline Finishing and Offline Finishing

Inline finishing integrates post-print processes such as cutting, folding, or coating directly within the printing workflow, enhancing efficiency by reducing handling and turnaround time. Offline finishing occurs separately from printing, allowing specialized machinery to focus on complex tasks but often increasing production time and labor. Understanding these distinctions helps you optimize your production line to balance speed, quality, and flexibility in your finishing operations.

Key Differences Between Inline and Offline Finishing

Inline finishing integrates the finishing process directly into the production line, allowing for continuous workflow and reducing handling time, whereas offline finishing occurs separately after the main production, providing flexibility for complex or customized tasks. Inline finishing is typically faster and more efficient for high-volume, standardized jobs, while offline finishing excels in quality control and specialized treatments. Key differences include process integration, speed, flexibility, and suitability for production scale and customization.

Workflow Integration: Inline vs Offline

Inline finishing seamlessly integrates with your printing workflow by completing post-print processes such as cutting, folding, or binding within the same production line, reducing manual handling and turnaround time. Offline finishing operates separately from the main printing process, requiring transfer of printed materials to dedicated finishing equipment, which may increase labor and delay delivery. Choosing inline finishing enhances workflow efficiency and accuracy, while offline finishing offers flexibility for complex or varied finishing tasks.

Speed and Efficiency Comparison

Inline finishing integrates finishing processes directly into the production line, significantly boosting speed by eliminating material transfer times between machines. Offline finishing requires separate equipment, leading to slower turnaround due to material handling and setup adjustments. Inline systems enhance overall efficiency by streamlining workflow and reducing labor costs, while offline finishing offers flexibility but at the expense of longer production cycles.

Flexibility and Customization Options

Inline finishing offers limited flexibility due to its integration within the production line, primarily designed for standardized processes with predefined customization options. Offline finishing provides extensive customization possibilities, allowing you to tailor finishing techniques to diverse projects without disrupting ongoing production. This flexibility ensures your finishing choices can evolve with changing demands and specialized requirements.

Equipment and Space Requirements

Inline finishing requires integrated equipment within the production line, optimizing space by minimizing separate machinery and reducing workflow disruptions. Offline finishing demands standalone equipment, necessitating additional floor space and often separate rooms to accommodate processes like binding, trimming, or coating. Equipment versatility and footprint differences significantly impact factory layout decisions between inline and offline finishing setups.

Cost Implications of Finishing Methods

Inline finishing reduces overall production costs by integrating finishing processes directly into the printing workflow, minimizing handling and labor expenses. Offline finishing often incurs higher costs due to additional equipment, increased labor, and potential for workflow delays. Choosing inline finishing improves efficiency and cost-effectiveness, especially for high-volume print runs requiring consistent quality.

Quality Control and Consistency

Inline finishing integrates quality control directly into the production line, ensuring real-time monitoring and immediate correction of defects, which enhances consistency across every unit produced. Offline finishing relies on separate quality inspections after the main process, potentially leading to variability and delays in detecting issues that affect product uniformity. Real-time feedback mechanisms in inline systems facilitate tighter control over finishing parameters, resulting in higher overall quality consistency compared to offline methods.

Ideal Applications for Inline and Offline Finishing

Inline finishing is ideal for high-volume print jobs requiring continuous production flow, such as direct mail, books, and catalogs, where printing and finishing happen simultaneously to save time and reduce handling. Offline finishing suits complex or specialized tasks like embossing, foil stamping, or intricate binding that require separate, precise equipment to ensure higher quality and customization. You can optimize your workflow by choosing inline finishing for speed and efficiency and offline finishing for advanced finishing effects and flexibility.

Choosing the Right Finishing Method for Your Business

Selecting between inline finishing and offline finishing depends on your business's production volume, budget, and workflow efficiency. Inline finishing integrates directly into the production line, boosting speed and reducing handling errors, ideal for high-volume, continuous runs. Offline finishing offers flexibility and customization for smaller batches or complex jobs but may increase turnaround time and labor costs.

Inline finishing vs offline finishing Infographic

libmatt.com

libmatt.com