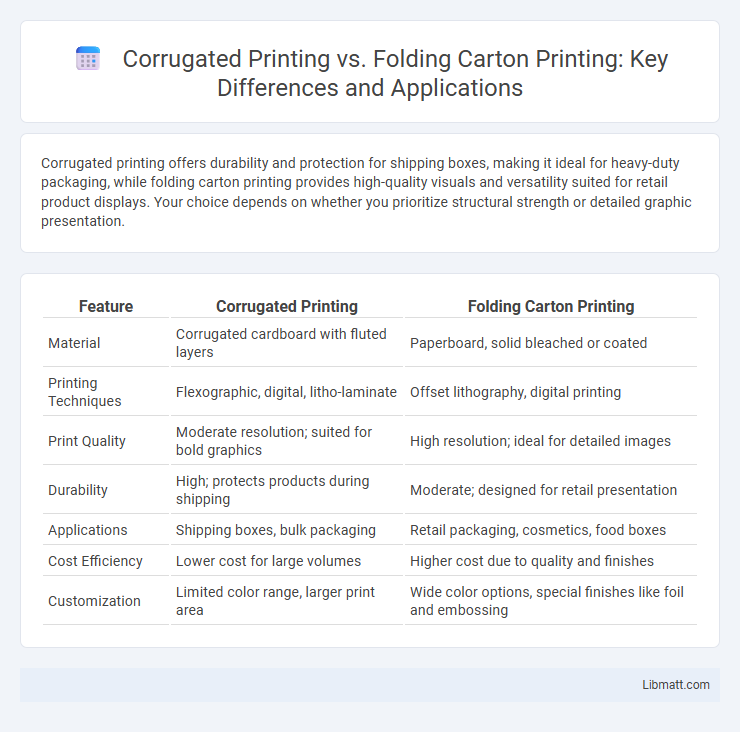

Corrugated printing offers durability and protection for shipping boxes, making it ideal for heavy-duty packaging, while folding carton printing provides high-quality visuals and versatility suited for retail product displays. Your choice depends on whether you prioritize structural strength or detailed graphic presentation.

Table of Comparison

| Feature | Corrugated Printing | Folding Carton Printing |

|---|---|---|

| Material | Corrugated cardboard with fluted layers | Paperboard, solid bleached or coated |

| Printing Techniques | Flexographic, digital, litho-laminate | Offset lithography, digital printing |

| Print Quality | Moderate resolution; suited for bold graphics | High resolution; ideal for detailed images |

| Durability | High; protects products during shipping | Moderate; designed for retail presentation |

| Applications | Shipping boxes, bulk packaging | Retail packaging, cosmetics, food boxes |

| Cost Efficiency | Lower cost for large volumes | Higher cost due to quality and finishes |

| Customization | Limited color range, larger print area | Wide color options, special finishes like foil and embossing |

Introduction to Corrugated and Folding Carton Printing

Corrugated printing involves producing graphics on corrugated board, a sturdy and lightweight material made from layered paperboard with fluted inner sheets, commonly used for shipping boxes and large packaging. Folding carton printing refers to the process of printing on flat paperboard that is later die-cut and folded into smaller retail packaging, often used for consumer goods like cosmetics, food, and pharmaceuticals. Both methods require specific printing technologies such as flexographic or digital presses, optimized for their respective substrates to ensure high-quality, durable, and visually appealing packaging solutions.

Key Differences between Corrugated and Folding Carton Printing

Corrugated printing involves printing on thick, multi-layered cardboard used primarily for shipping boxes, offering durability and protection, while folding carton printing is done on thinner, single-layer paperboard ideal for retail packaging and product presentation. Corrugated printing typically utilizes flexographic or digital processes designed to handle rougher textures and larger surfaces, whereas folding carton printing demands higher resolution techniques like lithography for sharp graphics and vibrant color accuracy. The key differences lie in substrate thickness, print quality requirements, and the intended use, with corrugated focusing on strength and functionality, and folding cartons emphasizing visual appeal and branding.

Materials Used in Corrugated vs Folding Carton Printing

Corrugated printing primarily uses kraft paper or recycled fiberboard with a fluted corrugated medium sandwiched between linerboards, offering strength and durability for packaging heavy or fragile items. Folding carton printing utilizes solid bleached sulfate (SBS), coated recycled board (CRB), or paperboard, designed for smooth surfaces that enhance graphic quality and are ideal for retail packaging. Your choice of material directly impacts the printing techniques and the structural performance of the final packaging product.

Printing Techniques: Flexography vs Offset

Flexography printing is commonly used for corrugated packaging due to its ability to print on uneven surfaces with fast drying inks, making it ideal for large runs and quick turnaround times. Offset printing, preferred for folding carton printing, provides high-resolution images and vibrant colors on smooth, flat surfaces, suitable for detailed graphics and premium packaging. Your choice depends on the packaging material and desired print quality, with flexography excelling in durability and speed while offset offers superior visual appeal.

Design Capabilities and Print Quality

Corrugated printing offers robust design capabilities tailored for large-format packaging, using flexible inks that adhere well to the textured, fluted surface, providing durable and vibrant prints suitable for shipping and display purposes. Folding carton printing excels in high-resolution graphics and intricate design details on smooth, flat paperboard, enabling superior color accuracy and sharpness, ideal for retail packaging and premium branding. While corrugated printing prioritizes durability and impact, folding carton printing emphasizes fine detail and visual appeal, making each suited to different market needs.

Cost Comparison: Corrugated vs Folding Carton

Corrugated printing generally costs less than folding carton printing due to the lower material expenses and simpler production process, making it ideal for bulk packaging or shipping needs. Folding carton printing involves higher costs driven by premium paperboard materials and intricate finishing options, suited for retail-ready packaging where aesthetics matter. Your choice between the two should reflect budget constraints and the packaging's functional or presentation requirements.

Applications and Industry Uses

Corrugated printing is widely used in shipping, packaging, and industrial applications due to its durability and ability to protect heavy or bulky goods during transit, making it ideal for e-commerce, food, and electronics industries. Folding carton printing, favored for retail packaging, cosmetics, pharmaceuticals, and consumer goods, emphasizes high-quality graphics and detailed designs to attract consumers on store shelves. Understanding these differences helps you choose the right printing method to optimize product presentation and protection based on your industry's specific needs.

Sustainability and Recyclability Factors

Corrugated printing utilizes kraft paper made from recycled fibers, making it highly sustainable and easily recyclable through standard curbside programs, which reduces environmental impact. Folding carton printing often involves coated or laminated materials that can complicate recycling processes due to the need for separation of layers, affecting overall recyclability. Choosing corrugated packaging supports circular economy initiatives by promoting the reuse of materials and minimizing landfill waste compared to folding cartons.

Lead Times and Production Efficiencies

Corrugated printing typically offers faster lead times due to its simpler production process and the use of larger sheets, enabling higher volume runs with quicker turnaround. Folding carton printing involves more intricate steps like die-cutting and gluing, which can extend production times but allows for detailed designs and precise packaging shapes. Your choice depends on whether speed and volume or design complexity and finish quality are more critical for your project.

Choosing the Right Printing Method for Your Packaging

Selecting between corrugated printing and folding carton printing depends on the durability and visual impact required for your packaging. Corrugated printing excels in strength and protection, ideal for shipping and heavy-duty applications, while folding carton printing offers high-quality graphics and precise folding for retail-ready displays. Understanding your product's packaging needs helps you choose a method that balances protection with eye-catching branding.

Corrugated printing vs folding carton printing Infographic

libmatt.com

libmatt.com