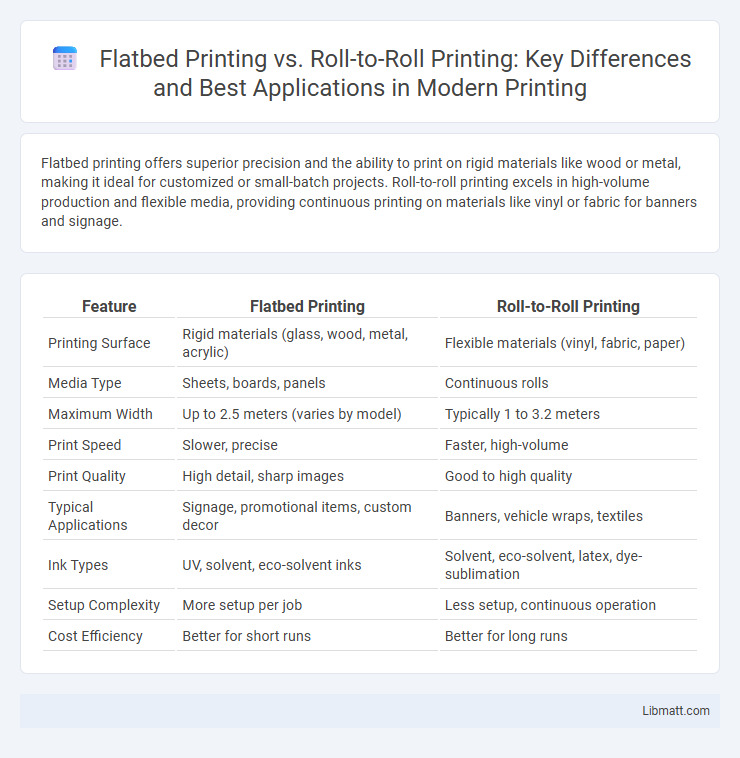

Flatbed printing offers superior precision and the ability to print on rigid materials like wood or metal, making it ideal for customized or small-batch projects. Roll-to-roll printing excels in high-volume production and flexible media, providing continuous printing on materials like vinyl or fabric for banners and signage.

Table of Comparison

| Feature | Flatbed Printing | Roll-to-Roll Printing |

|---|---|---|

| Printing Surface | Rigid materials (glass, wood, metal, acrylic) | Flexible materials (vinyl, fabric, paper) |

| Media Type | Sheets, boards, panels | Continuous rolls |

| Maximum Width | Up to 2.5 meters (varies by model) | Typically 1 to 3.2 meters |

| Print Speed | Slower, precise | Faster, high-volume |

| Print Quality | High detail, sharp images | Good to high quality |

| Typical Applications | Signage, promotional items, custom decor | Banners, vehicle wraps, textiles |

| Ink Types | UV, solvent, eco-solvent inks | Solvent, eco-solvent, latex, dye-sublimation |

| Setup Complexity | More setup per job | Less setup, continuous operation |

| Cost Efficiency | Better for short runs | Better for long runs |

Introduction to Flatbed and Roll-to-Roll Printing

Flatbed printing excels in producing high-quality prints on rigid materials like wood, glass, and metal, offering precision and versatility for diverse applications. Roll-to-roll printing specializes in continuous output on flexible substrates such as vinyl and fabric, ideal for large-format banners and vehicle wraps. Choosing between flatbed and roll-to-roll printing depends on your project's material type and size requirements.

Core Technologies: How Flatbed vs Roll-to-Roll Printing Work

Flatbed printing uses a stationary, flat surface where rigid or flexible substrates are placed, and inkjet print heads move across to deposit ink precisely, allowing high-resolution prints on materials like wood, glass, metal, and acrylic. Roll-to-roll printing employs continuous rolls of flexible materials fed through the printer, where ink is applied as the substrate moves, ideal for mass-production of banners, textiles, and wallpapers. The core technology difference lies in substrate handling: flatbed supports rigid, thick materials with stationary flatbeds, while roll-to-roll facilitates high-speed printing on flexible, continuous media.

Material Compatibility: Rigid vs Flexible Media

Flatbed printing excels in handling rigid media such as wood, glass, metal, and acrylic, allowing for direct printing on thick and uneven surfaces with high precision. Roll-to-roll printing is optimized for flexible materials like vinyl, fabric, and paper, enabling continuous high-speed production ideal for banners and wallpaper. This distinction makes flatbed printing suitable for durable, custom signage while roll-to-roll printing offers efficiency in large-volume flexible media applications.

Image Quality and Resolution Comparison

Flatbed printing offers superior image quality and higher resolution capabilities due to its controlled ink application on rigid materials, achieving crisp details and vibrant colors ideal for fine art and signage. Roll-to-roll printing excels in speed and volume, producing consistent quality on flexible substrates but generally at a lower resolution compared to flatbed printers. The choice depends on the project's demand for precision versus production efficiency, with flatbed printers preferred for high-detail graphics and roll-to-roll suited for large-scale banners and textiles.

Speed and Production Efficiency

Flatbed printing offers high precision and is ideal for rigid substrates but generally operates at slower speeds compared to roll-to-roll printing. Roll-to-roll printing excels in production efficiency, enabling continuous printing on flexible materials at much higher speeds, making it suitable for large-volume runs. Manufacturers seeking rapid turnaround for flexible media often prefer roll-to-roll due to its higher throughput and cost-effectiveness.

Cost Analysis: Equipment, Operation, and Maintenance

Flatbed printing typically incurs higher initial equipment costs due to specialized machinery capable of handling rigid substrates, while roll-to-roll printing offers lower capital investment optimized for flexible materials. Operational expenses for flatbed printers are generally increased by slower production speeds and more frequent maintenance of print heads and vacuum systems compared to the continuous, faster workflow of roll-to-roll printers. In terms of maintenance, flatbed printers require more downtime and skilled labor to recalibrate and clean, whereas roll-to-roll systems benefit from streamlined maintenance protocols, reducing overall long-term operational costs.

Print Size and Versatility

Flatbed printing offers exceptional versatility by allowing direct printing on rigid substrates up to several feet in size, accommodating various materials like wood, glass, and metal. Roll-to-roll printing excels in handling continuous flexible media, making it ideal for large-scale banners, fabrics, and wallpapers with unlimited print length. Your choice depends on the project scope, with flatbed best for diverse rigid items and roll-to-roll optimal for extended prints on flexible materials.

Ideal Applications for Each Printing Method

Flatbed printing excels in producing high-quality prints on rigid substrates such as glass, wood, metal, and acrylic, making it ideal for signage, displays, and custom promotional items. Roll-to-roll printing is best suited for high-volume printing on flexible materials like vinyl, textiles, and banners, commonly used for large-format advertising, vehicle wraps, and fabric graphics. Each method offers advantages depending on substrate type, print size, and production speed requirements.

Environmental Impact and Ink Usage

Flatbed printing uses UV-curable inks that often contain fewer volatile organic compounds (VOCs), reducing harmful emissions compared to the solvent-based inks commonly used in roll-to-roll printing. Flatbed printers typically minimize ink waste by applying precise amounts directly onto rigid substrates, enhancing ink efficiency and lowering environmental impact. Your choice between the two methods can significantly influence sustainability outcomes, as flatbed printing offers a cleaner, more eco-friendly solution with less hazardous ink disposal requirements.

Choosing the Right Printing Solution for Your Business

Flatbed printing offers precise, high-quality output on rigid materials such as wood, metal, and glass, making it ideal for customized, durable products. Roll-to-roll printing excels in speed and efficiency for large-volume prints on flexible substrates like vinyl and fabric, perfect for banners and vehicle wraps. Understanding your production needs helps you select the optimal printing technology to maximize quality and cost-effectiveness in your business.

flatbed printing vs roll-to-roll printing Infographic

libmatt.com

libmatt.com