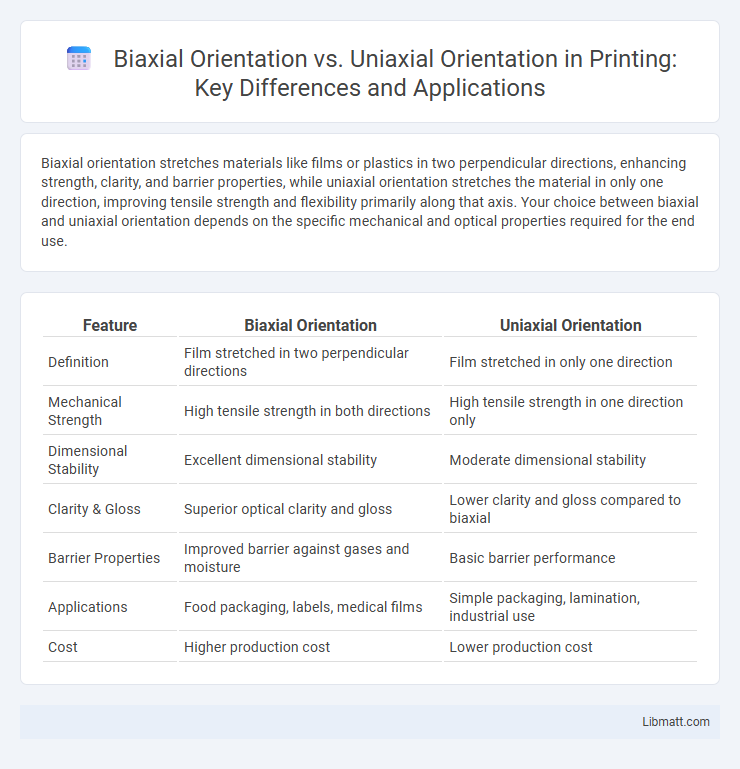

Biaxial orientation stretches materials like films or plastics in two perpendicular directions, enhancing strength, clarity, and barrier properties, while uniaxial orientation stretches the material in only one direction, improving tensile strength and flexibility primarily along that axis. Your choice between biaxial and uniaxial orientation depends on the specific mechanical and optical properties required for the end use.

Table of Comparison

| Feature | Biaxial Orientation | Uniaxial Orientation |

|---|---|---|

| Definition | Film stretched in two perpendicular directions | Film stretched in only one direction |

| Mechanical Strength | High tensile strength in both directions | High tensile strength in one direction only |

| Dimensional Stability | Excellent dimensional stability | Moderate dimensional stability |

| Clarity & Gloss | Superior optical clarity and gloss | Lower clarity and gloss compared to biaxial |

| Barrier Properties | Improved barrier against gases and moisture | Basic barrier performance |

| Applications | Food packaging, labels, medical films | Simple packaging, lamination, industrial use |

| Cost | Higher production cost | Lower production cost |

Introduction to Material Orientation

Material orientation in polymer films significantly impacts mechanical properties and performance, with biaxial orientation involving stretching in two perpendicular directions and uniaxial orientation stretching in only one direction. Biaxially oriented films offer enhanced tensile strength, clarity, and barrier properties, making them ideal for packaging applications requiring durability and flexibility. Understanding the differences helps optimize Your product design for specific end-use requirements by selecting the appropriate orientation method.

Defining Biaxial and Uniaxial Orientation

Biaxial orientation refers to the process of stretching a material, typically plastic film, in two perpendicular directions to enhance its mechanical strength, clarity, and barrier properties. Uniaxial orientation involves stretching the material in only one direction, improving tensile strength and stiffness along that axis but offering less overall dimensional stability. These orientation techniques are critical in manufacturing processes for packaging materials, where braxial orientation provides balanced strength and flexibility compared to the directional reinforcement of uniaxial orientation.

Manufacturing Processes Involved

Biaxial orientation involves stretching polymer films in both the machine and transverse directions during manufacturing, enhancing tensile strength and barrier properties. Uniaxial orientation stretches the material in only one direction, typically either the machine or transverse direction, resulting in anisotropic mechanical characteristics. The manufacturing processes include sequential or simultaneous stretching for biaxial orientation, while uniaxial orientation employs single-direction elongation techniques such as tenter frame or roll stretching.

Structural Differences and Properties

Biaxial orientation involves stretching a material, typically plastic films, in two perpendicular directions, enhancing strength, clarity, and barrier properties compared to uniaxial orientation, which stretches the material in only one direction. The biaxial process aligns polymer molecules in both directions, resulting in improved tensile strength and dimensional stability, whereas uniaxially oriented films provide strength predominantly along the stretch axis but less resistance across the other. Your choice between biaxial and uniaxial orientation impacts product durability, flexibility, and performance in packaging or industrial applications.

Advantages of Biaxial Orientation

Biaxial orientation enhances film strength by stretching the material both longitudinally and transversely, resulting in improved tensile strength and dimensional stability compared to uniaxial orientation. This process also provides superior clarity, barrier properties against gases and moisture, and better resistance to punctures and tears. Your packaging or manufacturing applications benefit significantly from biaxially oriented films due to these enhanced mechanical and optical qualities.

Benefits of Uniaxial Orientation

Uniaxial orientation enhances the mechanical strength and dimensional stability of materials by aligning polymer chains in a single direction, which improves tensile strength and resistance to stretching. This orientation is particularly beneficial for applications requiring targeted strength and flexibility, such as packaging films and industrial tapes. Uniaxial orientation also offers cost-effective production with simpler processing techniques compared to biaxial orientation.

Key Applications in Industry

Biaxial orientation enhances strength, clarity, and barrier properties of films, making it ideal for packaging applications in food, pharmaceuticals, and electronics, where durability and product protection are critical. Uniaxial orientation is commonly used in industries requiring stretchability and impact resistance, such as plastic strapping and rubber industry components. Your choice between biaxial and uniaxial orientation depends on the specific mechanical and barrier properties needed for optimal product performance in various industrial sectors.

Performance Comparison: Strength and Durability

Biaxial orientation enhances film performance by stretching the material in two perpendicular directions, resulting in superior tensile strength, improved impact resistance, and greater durability compared to uniaxial orientation, which stretches the film in only one direction. This multidirectional stretching provides better dimensional stability and resistance to tearing, making biaxially oriented films ideal for flexible packaging and high-performance industrial applications. Your choice of biaxial orientation ensures enhanced durability and mechanical robustness tailored for demanding environments.

Cost Implications and Efficiency

Biaxial orientation enhances material strength and clarity by stretching films in two perpendicular directions, leading to higher production costs compared to uniaxial orientation, which stretches in only one direction. This increased manufacturing complexity requires specialized equipment, impacting initial investment and operational expenses but yields superior barrier properties and dimensional stability. In contrast, uniaxial orientation offers lower processing costs and faster production times, making it efficient for applications where cost sensitivity outweighs advanced performance requirements.

Future Trends in Material Orientation Technologies

Future trends in material orientation technologies emphasize enhanced mechanical properties and improved barrier performance through advanced biaxial orientation techniques. Innovations such as multi-axial orientation and nano-engineered polymers are driving the development of lighter, stronger films used in packaging, automotive, and electronics industries. Uniaxial orientation remains relevant for specific applications requiring directional strength, but biaxial orientation dominates due to its superior uniformity and flexibility in performance characteristics.

Biaxial Orientation vs Uniaxial Orientation Infographic

libmatt.com

libmatt.com