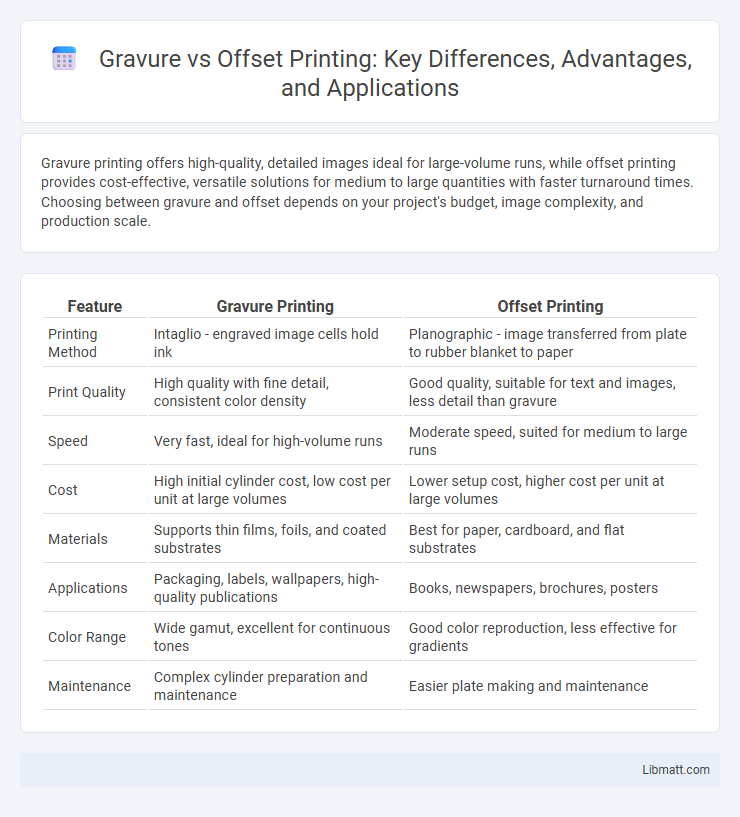

Gravure printing offers high-quality, detailed images ideal for large-volume runs, while offset printing provides cost-effective, versatile solutions for medium to large quantities with faster turnaround times. Choosing between gravure and offset depends on your project's budget, image complexity, and production scale.

Table of Comparison

| Feature | Gravure Printing | Offset Printing |

|---|---|---|

| Printing Method | Intaglio - engraved image cells hold ink | Planographic - image transferred from plate to rubber blanket to paper |

| Print Quality | High quality with fine detail, consistent color density | Good quality, suitable for text and images, less detail than gravure |

| Speed | Very fast, ideal for high-volume runs | Moderate speed, suited for medium to large runs |

| Cost | High initial cylinder cost, low cost per unit at large volumes | Lower setup cost, higher cost per unit at large volumes |

| Materials | Supports thin films, foils, and coated substrates | Best for paper, cardboard, and flat substrates |

| Applications | Packaging, labels, wallpapers, high-quality publications | Books, newspapers, brochures, posters |

| Color Range | Wide gamut, excellent for continuous tones | Good color reproduction, less effective for gradients |

| Maintenance | Complex cylinder preparation and maintenance | Easier plate making and maintenance |

Introduction to Gravure and Offset Printing

Gravure printing utilizes engraved cylinders to transfer ink onto various substrates, offering high-quality, consistent images ideal for long print runs such as packaging, magazines, and wallpaper. Offset printing employs a plate-based process where ink is transferred from a plate to a rubber blanket, then to paper, providing sharp, detailed prints suitable for commercial materials like brochures and books. Both methods serve distinct purposes by balancing factors like image fidelity, printing speed, and cost efficiency.

Core Principles of Gravure Printing

Gravure printing operates on the principle of engraving images onto a cylinder, where recessed cells hold ink that transfers onto the substrate during printing. This technique relies on varying cell depths and sizes to control ink volume and achieve high-resolution, consistent image quality. The continuous tone capability and precise ink deposition make gravure ideal for long print runs requiring rich color vibrancy and fine detail.

Fundamentals of Offset Printing Technology

Offset printing technology relies on the principle of lithography, where ink is transferred from a plate to a rubber blanket before reaching the printing surface, ensuring precise and high-quality image reproduction. This indirect printing method uses the immiscibility of oil and water to keep non-image areas ink-free, enabling sharp and consistent prints across large volumes. Offset presses excel in producing detailed text and graphics on paper, making them ideal for newspapers, books, and brochures.

Key Differences Between Gravure and Offset

Gravure printing uses engraved cylinders for high-quality, long-run production with consistent color density, making it ideal for packaging and magazines. Offset printing employs flat plates to transfer ink onto a rubber blanket before paper, excelling in short to medium runs with sharp detail and cost efficiency. Your choice hinges on run length, budget, and print quality requirements, as gravure suits large volumes while offset offers versatility and faster setup.

Print Quality Comparison: Gravure vs Offset

Gravure printing offers superior print quality with rich, continuous tones and excellent color depth due to its engraved cylinders that transfer ink directly onto the substrate. Offset printing delivers sharp and precise images through its indirect ink transfer process, ideal for high-detail work but may lack the vibrancy and smooth gradient transitions seen in gravure. Your choice depends on print volume and quality needs, with gravure excelling in large runs requiring consistent, high-fidelity output, while offset suits short to medium runs with fine detail.

Cost Implications: Initial Setup and Production

Gravure printing demands higher initial setup costs due to the engraving of cylinders, making it cost-effective primarily for high-volume production runs. Offset printing features lower initial setup expenses with the use of plates, offering better economical viability for shorter print runs. Production costs in gravure decrease significantly as volume increases, while offset maintains more consistent per-unit costs across different quantities.

Ideal Applications for Gravure Printing

Gravure printing excels in high-volume production runs such as packaging, labels, and magazines, where consistent, rich color quality is essential. Its ability to print fine details and photographic images makes it ideal for complex designs and long-lasting print jobs. Your choice of gravure ensures superior quality and efficiency for bulk orders requiring vibrant, durable results.

Best Use Cases for Offset Printing

Offset printing excels in high-volume production runs requiring consistent, high-quality images, making it ideal for newspapers, magazines, brochures, and books. Its ability to print on a wide range of substrates, including paper, cardboard, and plastic, supports diverse commercial applications such as packaging and direct mail. Cost-efficiency improves significantly with larger print quantities, due to the durability of offset plates and faster print speeds compared to gravure printing.

Environmental Considerations in Both Methods

Gravure printing uses solvent-based inks that can emit volatile organic compounds (VOCs), requiring effective ventilation and waste treatment to minimize environmental impact. Offset printing offers water-based or soy-based inks with lower VOC emissions, making it a more eco-friendly option in terms of ink composition. Both methods generate paper waste and energy consumption, but offset generally has less environmental burden due to its more efficient ink usage and faster setup times.

Choosing the Right Printing Method for Your Needs

Gravure printing offers exceptional image quality and durability, making it ideal for high-volume projects like magazines and packaging that require rich detail and vibrant colors. Offset printing is cost-effective for medium to large runs, delivering sharp images with versatile substrate options, perfect for brochures, flyers, and business stationery. You should consider the print quantity, budget, and desired finish to select the method that best aligns with your printing needs.

Gravure vs offset Infographic

libmatt.com

libmatt.com