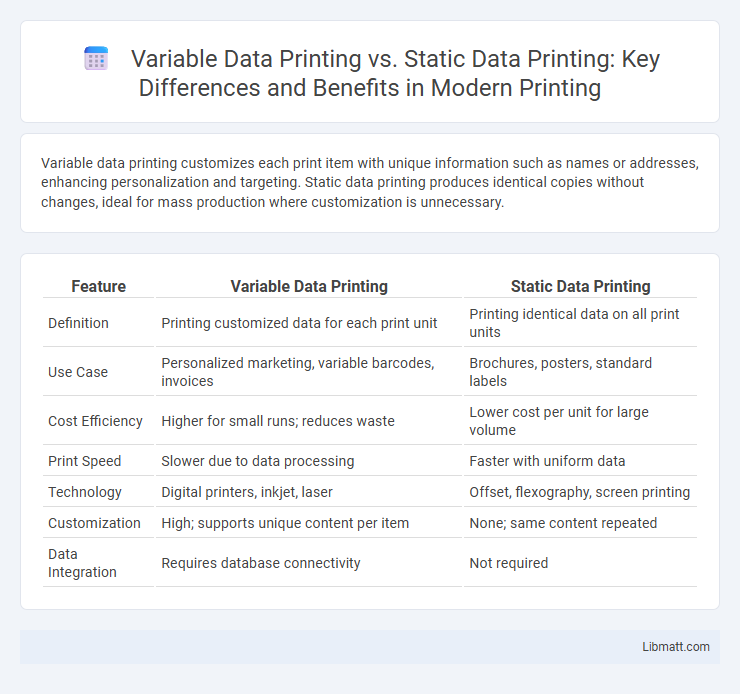

Variable data printing customizes each print item with unique information such as names or addresses, enhancing personalization and targeting. Static data printing produces identical copies without changes, ideal for mass production where customization is unnecessary.

Table of Comparison

| Feature | Variable Data Printing | Static Data Printing |

|---|---|---|

| Definition | Printing customized data for each print unit | Printing identical data on all print units |

| Use Case | Personalized marketing, variable barcodes, invoices | Brochures, posters, standard labels |

| Cost Efficiency | Higher for small runs; reduces waste | Lower cost per unit for large volume |

| Print Speed | Slower due to data processing | Faster with uniform data |

| Technology | Digital printers, inkjet, laser | Offset, flexography, screen printing |

| Customization | High; supports unique content per item | None; same content repeated |

| Data Integration | Requires database connectivity | Not required |

Introduction to Variable Data Printing vs Static Data Printing

Variable data printing (VDP) allows for the customization of printed materials by changing text, graphics, or images on each piece without stopping the press, enhancing personalization and targeting. Static data printing produces identical copies of a printed piece, maintaining uniform content and design across the entire print run, ideal for mass production. VDP leverages digital printing technology to efficiently manage dynamic data sets, whereas static printing typically relies on traditional methods like offset printing.

What is Variable Data Printing?

Variable Data Printing (VDP) is a digital printing technique that allows customization of each printed piece by changing text, graphics, or images from one print to the next without stopping or slowing down the process. Unlike static data printing, which produces identical copies, VDP enables personalized marketing materials, direct mail, and labels tailored to individual recipients. Your business benefits from increased engagement and response rates by utilizing targeted content through variable data printing.

What is Static Data Printing?

Static data printing involves producing identical information on every printed piece within a batch, such as fixed text, logos, or images used for mass production. This method is ideal for items like brochures, flyers, or labels where the content remains unchanged across all copies. Static data printing ensures consistency and cost-efficiency in high-volume print runs without individual customization.

Key Differences Between Variable and Static Data Printing

Variable data printing customizes each printed piece with unique elements like names, addresses, or images, enhancing personalization for targeted marketing campaigns. Static data printing produces identical copies, ideal for documents requiring consistent information such as brochures or flyers. Your choice depends on whether customization or uniformity best suits your printing needs.

Technology Behind Variable Data Printing

Variable data printing (VDP) utilizes digital printing technology that allows customization of individual pieces within a print run by altering text, graphics, and images based on stored database information. Unlike static data printing, which uses traditional offset or lithographic presses producing identical copies, VDP harnesses inkjet or laser printers controlled by software to dynamically modify content in real-time. This technology enables personalized marketing, direct mail, and transactional printing with increased efficiency and reduced waste.

Advantages of Variable Data Printing

Variable data printing offers significant advantages by enabling personalized and targeted communication that enhances customer engagement and response rates. With the ability to customize text, images, and graphics on each printed piece, it improves marketing efficiency and ROI compared to static data printing. Your campaigns benefit from increased relevance and flexibility, allowing real-time updates and reduced waste.

Benefits and Limitations of Static Data Printing

Static data printing offers high-speed production and cost efficiency for large volumes of identical items by using fixed images or text. Limitations include lack of customization, making it unsuitable for personalized marketing or variable product information. This method excels in applications where consistency and uniformity are critical, such as packaging and labeling in mass production.

Common Applications of Variable Data Printing

Variable data printing is widely used in personalized marketing campaigns, including customized direct mail, promotional materials, and product labels that change based on recipient information. This technology enables targeted communication by integrating unique customer data such as names, purchase history, or location, enhancing engagement and response rates. Your business can leverage variable data printing to deliver relevant offers and improve customer experience, unlike static data printing, which produces uniform copies without customization.

Cost Comparison: Variable vs Static Data Printing

Variable data printing (VDP) often incurs higher costs than static data printing due to the need for specialized digital printing equipment and customized workflows that handle unique data for each printed piece. Static data printing benefits from economies of scale, as identical copies can be produced efficiently using traditional offset or digital methods, reducing per-unit costs significantly. While VDP delivers personalized content that can boost engagement and ROI, businesses must balance these advantages against the increased expenses associated with data management and printing complexity.

Choosing the Right Printing Method for Your Project

Variable data printing offers personalized content tailored to each recipient, ideal for targeted marketing campaigns and customized product labels. Static data printing suits high-volume jobs with consistent content, such as bulk brochures or flyers, where uniformity and lower cost per unit are crucial. Evaluating project goals, print run size, and budget ensures the selection of the most efficient and cost-effective printing method.

variable data printing vs static data printing Infographic

libmatt.com

libmatt.com